Hot Press Veneer Professionals are More Successful and Profitable with Sing Core

For years, Sing Core has been providing high-end local and nationwide hot press veneer professionals with premium core material that eliminates the need for crossbanding.

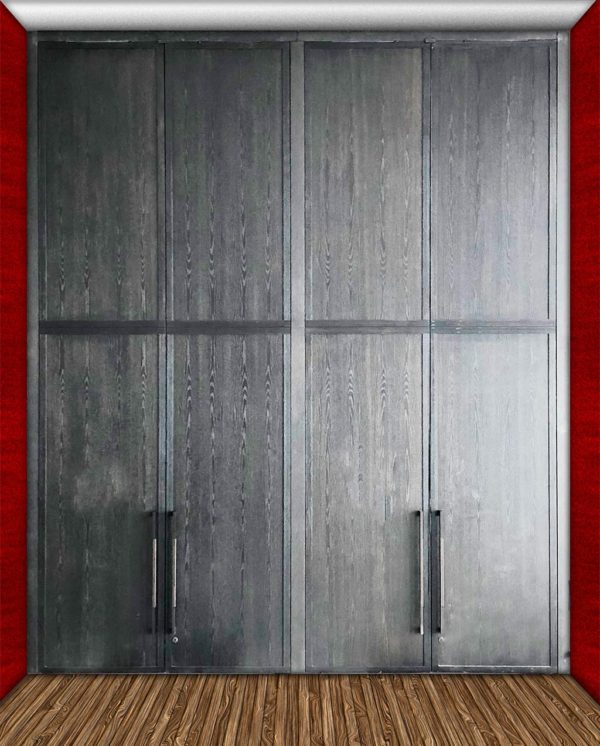

Let’s face it, nothing can compete with the beauty and elegance of a perfectly hot-pressed panel, and for that sweet-spot in the marketplace, those clients that demand the best and are willing to pay for it. The manufacturers and millworks that have Sing Core inside their hot-pressed products are making bank by specializing in these ultra-high-end projects.

For general contractors, we recommend using your local millwork to lay veneer, as it requires a skilled professional.

From the Inventor of Sing Core

I get asked by hot press veneer shops, if we are in competition with them? And the answer is, “No.” Even though we are specified by architects all over the country in large veneer projects, and mostly in huge veneer doors, we do not do the veneer. What we do is to provide our substrate to the best hot press veneer professionals we know. If a contractor contacts us first because we were spec’d on the job, we have him tell us which veneer company he wants us to work with, and my team is willing to help match up the best material and veneer services if they ask us for their advice, and that’s what we do.

I have invented patented and patent-pending solutions for high precision veneer projects that take the pain out of the challenges normally associated with big, long-spanning high-end jobs, anywhere from the San Francisco MOMA to the top of the World Trade Center’s Freedom Tower.

The top reasons the architects specify Sing Core is because

- We use only the best hot-press veneer companies to apply the best veneers, because I understand that doing veneering really great is an art, and we suggest only using the best artist, as you would on any important project.

- My company does what we do best, that is to provide the best substrate for veneer specialists to lay high quality veneer with the best guarantees in the woodworking industry.

- The people and companies that I work with are the best in their field and they don’t have to worry anymore about if this will work or how to solve problems associated with weight, dimensional stability, warping, or long lifespan. We’ve spent years in R&D to make sure that the biggest doors in the world do not have to warp anymore, and the biggest door companies trust me to make it so. In the last 10 years, they have not reported a single failed door, even including doors of immense size. Not one.

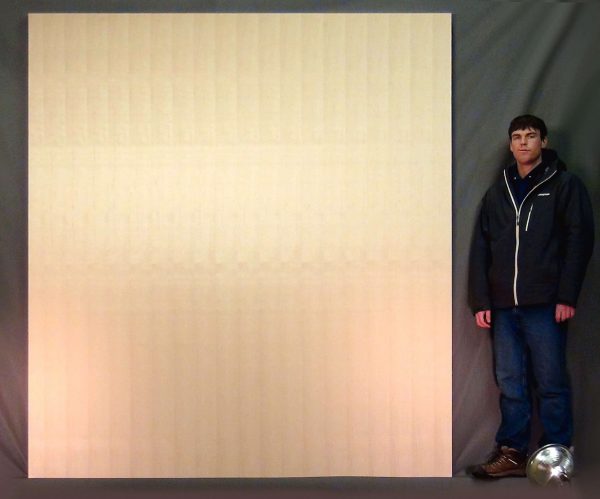

- My core is stronger than steel pound for pound and less than 1/3 the weight of doors made of solid wood core. Sing Core provides a high precision strong full bonding surface for veneering to that is so smooth crossbanding is not required. How high precision? Try +/- .oo6 inch, compare that to any other core material.

- Sing Core has insulation for enjoying warmth in Winter and cool Summers, is sound deadening for peace and quiet, and more dimensionally stable than other type of core such as foam core, honeycomb core, wood-based core.

You may not see everything we do because it is hidden deep inside the door or panel, but it’s there and many people can sleep soundly at night knowing that we have done all the hard work in advance, so that you don’t have to worry about endless maintenance calls.

I am so proud of my invention, that I put my name on it: Sing Core

~ Peter Sing

What makes a hot-pressed panel worth so much more with Sing Core inside?

Architects are increasingly specifying their large high-end hot pressed veneer panelized walls, features, and doors have Sing Core inside (accounting for about one-third of all our products which are sent to the greater New York-area). The contractors generally contact Sing Core directly first, due to being specified. Though Sing Core does not actually do the veneering. Sing Core provides the high precision substrate that is shipped 3,000 miles from the manufacturing location in Washington State, to the high end millwork in New York (or wherever the nearest hot press specialist is near the construction site) to do the veneering there.

You will find Sing Core inside high-end hot pressed veneered ceilings, walls, floor, and doors in the most demanding architectural designs and projects.

Why?

Why must architects and designers go through such an unusual process to meet the needs of these high production and precision projects? According to those who are specifying and using Sing Core in their projects,

“There’s just no other way to do it.”

Large Size Concept Consideration

In an age when the biggest projects often include large spanning surface areas wrapped in beautiful wood veneer, the large scope of such a project is problematic. You are dealing with immense spans of material which is difficult to maintain straight and true, because at that size, most material will begin to move with changes in temperature, humidity, or other environmental variations. Sing Core is the only known method of keeping these spans straight and true. That is why the biggest door companies use Sing Core inside their doors that are over 9 ft. tall, because it doesn’t take much movement in a large door to render it inoperable. Then you do not have a door, you have an obstacle, or a bowed wall that needs to be dealt with. This leads to Sing Core’s primary function in these huge projects,

Warp-Free Hot Pressed Veneer

Particularly in high-end designs featuring the beauty of hot pressed veneer, the last thing you want is your project to express variances or changes. The desire is to have a completely flat surface that can span great length without warping. This is what Sing Core provides. It is the reason large doors (even extremely large doors) are guaranteed not to warp, bend, twist, or otherwise fail for 50 years, because they have Sing Core inside.

Highest Precision

High precision is a sought-after attribute of some of the most demanding clients, and Sing Core’s high precision (+/- .006 tolerance) gives them the high end performance that your clients are willing to pay extra for.

Lightweight Veneer Panels

Hot pressed veneer panels with Sing Core inside weigh less, not much more than a hollow core panel, but feature a fully insulated warp-free solid hybrid core that is 100% surface-area bondable. We do not provide hardware or veneering. If asked to lay veneer, we subcontract out to the best veneering professionals.

100% Surface Bondable

That means, no weak spots like you might see in honeycomb-type cores, which offer only 10% or less surface bonding area. This full-bonded surface area inside the panel eliminates delamination over time.

Fully Insulated Veneer Panels

The insulation value is important in high-end hot pressed veneer applications for both climate control and sound deadening capabilities within expansive structure designs.

Less Expensive to Deploy and Install

Keeping these hot pressed veneer panels lightweight translates to less expensive shipping, handling, and hardware. They are easier to and less expensive to transport, manage and install on site with fewer risk of injuries, even if the panel is exceptionally large.

50-Year Guarantee

The non-warping hybrid core allows large door companies to build large doors that can be guaranteed not to warp, bend, twist, or otherwise fail, including delamination.

We Do Not Veneer

We always recommend using your local veneering professionals for custom veneer doors. We do not provide veneer or install it. It is our policy to subcontract veneering jobs to the best veneering professionals in the USA.

If you offer hot-pressed veneer services or cold-press veneering to your clientele, your highest paying customers will gladly pay you more if your panels have Sing Core inside.