When it comes to exterior doors, durability, security, and aesthetic appeal are paramount. SingCore exterior doors stand out in the market as a revolutionary choice, offering a unique blend of strength, lightweight construction, and eco-friendly materials. In this article, we will explore the innovative features that make SingCore exterior doors a top choice for homeowners and builders alike.

Unparalleled Strength:

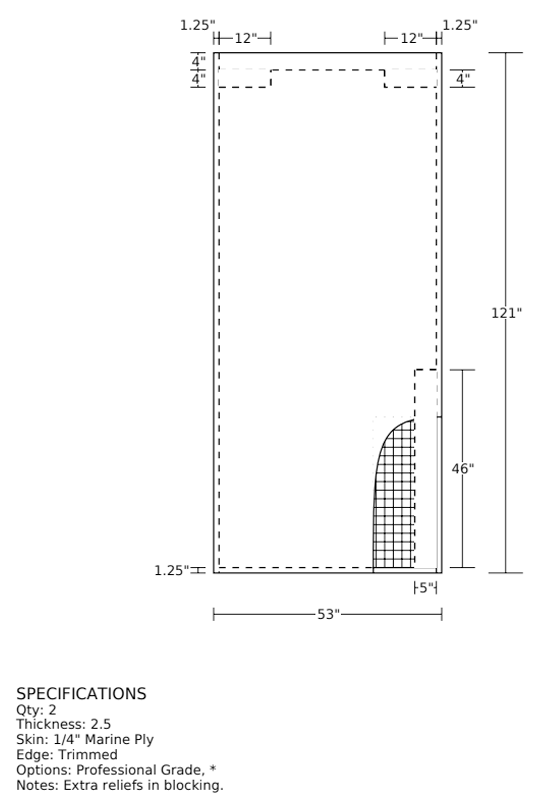

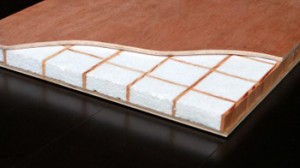

SingCore exterior doors are renowned for their exceptional strength. The secret lies in the core material – a patented Sing Core. This core is a composite of vertical grain torsion box structural grid and foam, resulting in a door that is incredibly lightweight yet stronger than traditional solid wood doors. This design ensures that the doors are resistant to warping, bending, and other common issues associated with wooden doors, providing long-lasting performance and structural integrity.

Lightweight Construction:

One of the standout features of SingCore exterior doors is their lightweight construction. Traditional solid doors can be heavy and cumbersome, making installation and daily use a challenging task. SingCore’s innovative design significantly reduces the weight of the door without compromising on strength. This makes installation easier and ensures that the doors are easy to handle on a day-to-day basis. The reduced weight also puts less stress on hinges and hardware, contributing to the overall longevity of the door.

Eco-Friendly Materials:

SingCore is committed to sustainability, and their exterior doors reflect this dedication. The use of eco-friendly materials in the construction of SingCore doors makes them an environmentally conscious choice. The torsion box core is made from renewable wood sources, and the manufacturing process minimizes waste. Choosing SingCore exterior doors not only benefits homeowners with a high-quality product but also contributes to a greener and more sustainable future.

Versatile Design Options:

SingCore exterior doors are not just about strength and durability; they also offer a wide range of design options to suit various architectural styles. Homeowners and builders can choose from a variety of finishes, veneers, and styles to match the aesthetics of any project. Whether you prefer a classic wood finish or a modern, sleek look, SingCore doors can be customized to meet your specific design preferences.

In the world of exterior doors, SingCore stands out as a game-changer. With a focus on strength, lightweight construction, eco-friendly materials, and versatile design options, SingCore exterior doors provide an innovative solution for those seeking a durable, reliable, and aesthetically pleasing entryway. As the demand for sustainable and high-performance building materials continues to grow, SingCore doors represent a forward-thinking choice for residential and commercial projects alike.

Barn doors constructed with Sing Core offer

Barn doors constructed with Sing Core offer  Unparalleled Strength and Lightweight Construction

Unparalleled Strength and Lightweight Construction Versatile Design Options

Versatile Design Options Large Panels and Seamless Integration

Large Panels and Seamless Integration Acoustic and Thermal Insulation

Acoustic and Thermal Insulation Durability and Low Maintenance

Durability and Low Maintenance