Sing Core and Your Build

Sing Core provides many benefits to permanent structures and designs, but what about portable ones? What value comes with using Sing Core for your tiny house, expo setup, or other portable structure? In this article we will answer that question, and explain how Sing Core can make your portable build so much better.

What are Portable Structures?

Portable structures are builds, projects, and other miscellaneous designs that are made to be portable. While different people may have different opinions on what makes things “portable”, it ultimately comes down to a few key requirements: size, weight, and durability. Portable things are hardly portable if they’re too big and heavy to move, and you wouldn’t even want to bother with a “portable” object that’s going to break within just a few uses.

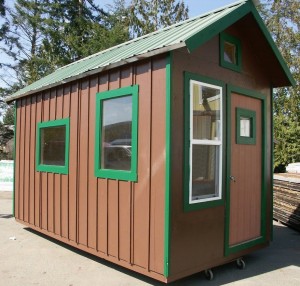

A few examples of portable structures include: tiny houses, trades show/expo booths and displays, teardown buildings, etc. In general, portable structures need to be able to be moved either with or without disassembling them, and this presents a number of problems and possible complications.

Portable Structure Problems

Portable structures face many potential issues, particularly when being transported. Structures like tiny houses must be stable, well crafted, and tightly secured otherwise they risk severe damage during travel. Trade show walls need to be lightweight enough to be moved and assembled by one person, but sturdy enough to support product and sign boards. No matter the portable structure, it presents a significant chance of being damaged or destroyed if not built and handled properly. That’s where Sing Core comes in.

The Sing Core Solution

Sing Core alleviates the pains of dealing with portable structures significantly. Sing Core is already used to build high end tiny houses and the best trade show panels out there, and it can be used to build many more projects as well. The lightweight and strong nature of our product lends itself to being used for portable structures, as it reduces the risk of the previously mentioned complications.

Sing Core panels are much lighter than the standard building choices, no matter the size of the panel. Not only does this make transporting large portable structures possible, it also makes assembling and disassembling them much simpler and less dangerous. Trade show displays can be easily moved and assembled, pop-up structures can be put up and torn down much quicker and safer, and more. The lightweight benefits to using Sing Core for your portable structure are significant, but it doesn’t just end there. Our panels are also pound-for-pound stronger than steel, so you don’t have to worry about sacrificing strength for ease of use and transport. You also don’t have to worry about your structure warping or breaking, as all of our panels come with a 50 Year Warp-Free and Structural Guarantee.

So, by using Sing Core for your portable structure, you get a lighter, stronger, and easier to use end result, as well as a guarantee that it will last for at least 50 years. If you’re considering using Sing Core for your project, feel free to submit a quote request from our pricing page, and we’ll get in touch!