The best door distributers represent the best in trusted door manufacturers across America for high confidence and superior door manufacturing ethics which translate to high quality and performance standards for upholding your credibility and professional ability to deliver only the best doors for your clientele.

What About Large Doors?

If you are like other distributors of the top selling doors from companies like VT Industries, you are getting some of the most coveted door jobs in your area of expertise. That is, for everything within the standard door size-range. Large doors are another thing altogether.

Large Doors

Large doors in your door schedule are going to be a problem. First off, your regular door supplier does not carry them, doesn’t want to build them, and doesn’t want you to sell them.

Why?

Because large doors fail. Even in the best of circumstances, with all the talent and expertise in making and installing millions of standard-sized doors, your supplier is unable to provide you with a door that will not fail after installation if its dimensions exceed 4×8.

Any door over 4×8 is going to present your valued client with problems. This is why large oversized doors are excluded from your standard warranty which covers the rest of the door schedule, because everyone knows that a large door will warp if it is over 4×8.

Where Does Your Door Supplier Go for Large Doors?

Every once and a while your door manufacturer takes on a large door job, which may include hundreds of standard-sized doors and a few large pivot doors, large sliding doors, or large hinge doors. What then? They don’t want to lose the job due to only a few large doors.

So, what do they do?

The biggest and best door manufacturers in the world know there is only one trusted door manufacturer in the world that can make a large door that will not warp, bend, twist, cup, or otherwise fail, and that is Sing Core.

Sing Core Warp-free Large Oversized Doors

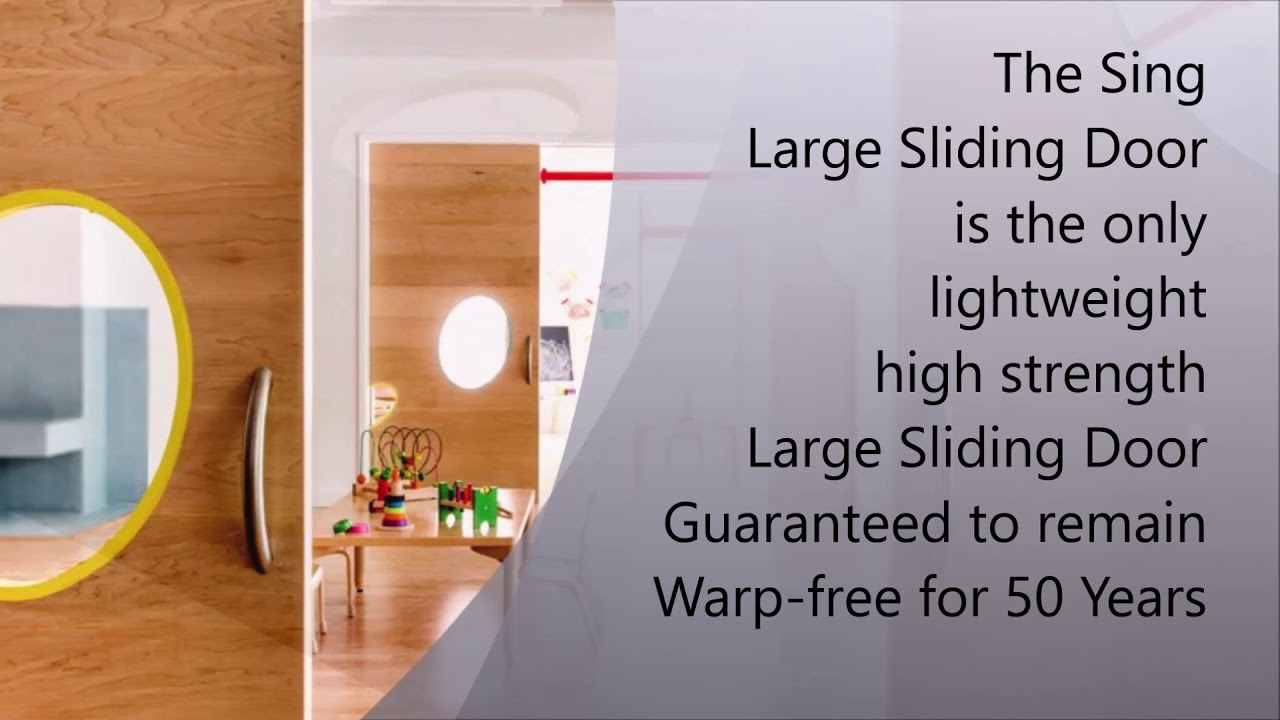

Enter Sing Core, the only large architectural door manufacturer in the United States who can build a large oversized door of any type or style that can build a large door of any material specified by your architect that can be lightweight, high strength, fully insulated, and can be guaranteed warp-free, not to fail, including a full structure warranty for fifty years.

Made in the USA

Sing Core doors are sustainable Eco-friendly doors which are proudly made by hand using safe domestic materials via our patented manufacturing methods using less energy, with very little waste, and a highly honorable respect for managing the best of nature’s materials and recycled materials for long almost service-free long life now and for generations to come.

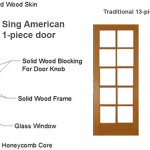

Sing Core Door Characteristics

Besides being lightweight, warp-free, and stronger than steel pound for pound, Sing Core Eco-friendly doors bring many other high-end attributes to the end product which will be enjoyed by your clientele for years to come, adding even more value to your Sing Core door.

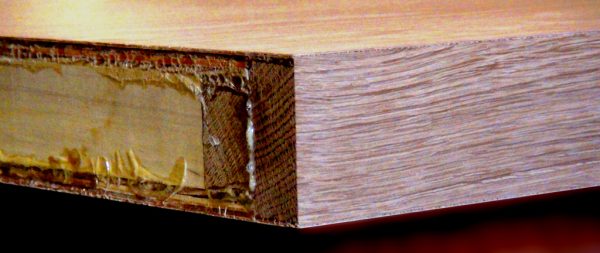

Some of the advantages of having a Sing Core door include being fully insulated for climate control and sound deadening qualities thanks to the high-precision (+/- .006 in. tolerance) patented and patent pending composite reinforced door core.

We Don’t Make Doors

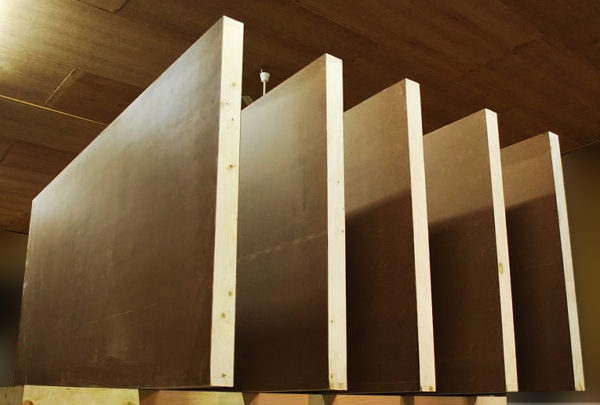

Even though the best doors in the world are made with Sing Core inside, we don’t actually make doors at all. What we build is the best non-warping insulated door blanks in the world. We work hand-in-hand with the best door manufacturers in the world to provide your clients with the best doors in the world of any size, even huge mammoth-sized doors.

In this arrangement, as we help support the best door builders, we provide them with the non-warping substrate (what we do best) as we trust them with handling the door finishing, hardware, and installation (what they do best).

What We Can Do

We do provide your biggest and best door manufacturers with the best support system and can provide them with door blanks in various stages of readiness for them to complete in their door factories.

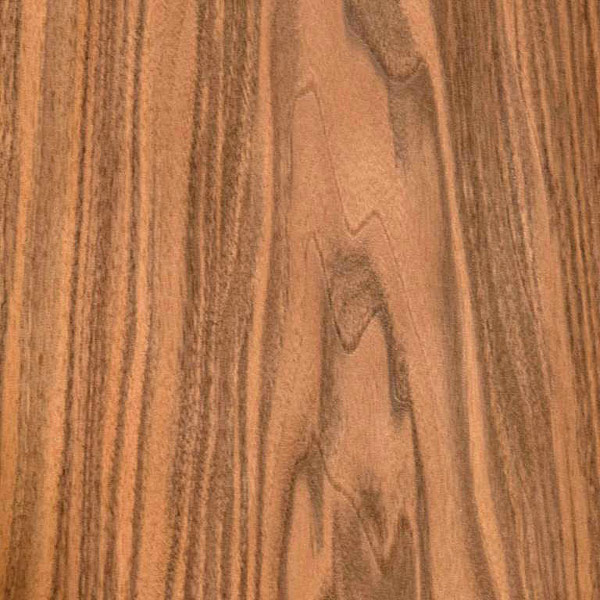

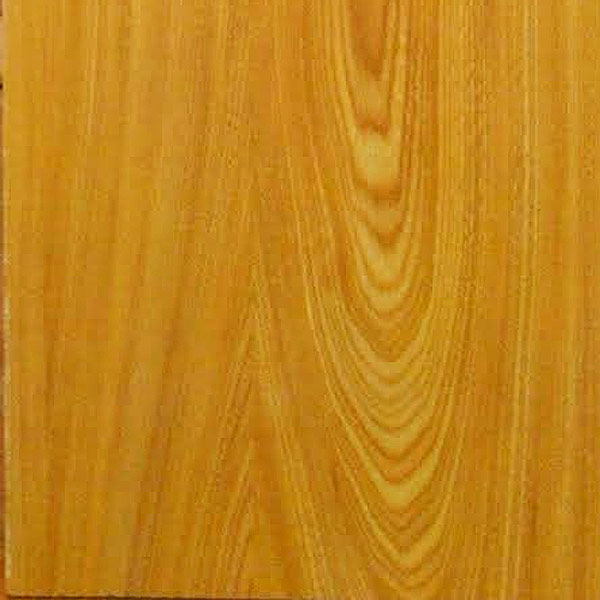

We are often called upon to make bulk runs of standard door blanks quickly, provide door builders with ready-to-finish door blanks prepared by attaching any available flat building materials, such as any species of natural wood grain veneer, natural wood planks, aluminum, cold rolled steel, concrete, fiberglass, FRP, galvanized steel, hot rolled steel, HPL, LVL, MDF, MDO, plywood, stainless steel, just to name a few, ready for your favorite door manufacturer or millwork to finish.

What We Can Do for You

If you have a good local custom door manufacturer or millwork that you work with locally you can order your Sing Core door blanks and have them sent directly to your favorite millwork or custom door maker for finishing, installation of hardware, and installation.

How to Get a Sing Door

You can get your Sing Door blank custom built to your architectural specifications by clicking on the orange Pricing button at the top of the page.

Thank you for supporting Sing Core

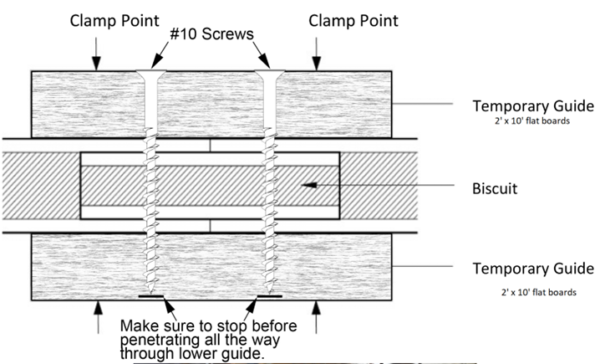

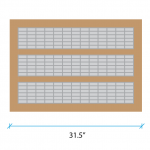

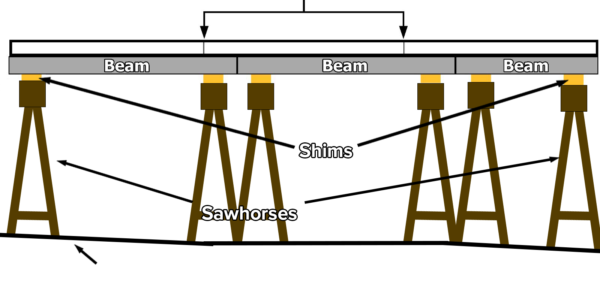

Each biscuit and slot are precisely cut to join with the greatest strength. After applying the glue to the slot and biscuit, do not use an excessive amount of glue. If the air is very dry a light misting of water can help the bond and cure time of the glue. Carefully push or hammer each biscuit lightly in place into the edge of one panel. Tap in with a rubber mallet.

Each biscuit and slot are precisely cut to join with the greatest strength. After applying the glue to the slot and biscuit, do not use an excessive amount of glue. If the air is very dry a light misting of water can help the bond and cure time of the glue. Carefully push or hammer each biscuit lightly in place into the edge of one panel. Tap in with a rubber mallet.