There is no doubt that Sing Core is responsible for the best doors in the world that can be built in any size for any functional purpose that can be guaranteed to not warp, bend, twist or otherwise fail for a full fifty years of regular use, even though Sing Core does not build doors.

Some individuals can be confused when they visit Sing Core and expect to just buy a pre-hung door that is the best door in the world, only to find that Sing Core does not actually make the door. Sing Doors are made of Sing Core, although we only supply the pre-configured base door material to achieve the results sought by the most demanding clients in the world.

Standard Size Sing Door Blanks

By popular demand SingCore introduces patented door core in economical and easy-to-use standard door width door blanks.

How does it Work?

In the real world, an architect, engineer, designer or the client conceives of the concept of their desired door. In many cases the high concept doors are problematic; some of them are large doors, which tend to fail due to their enormous size, while others may feature exotic materials that are susceptible to warp. Sing Core has the technology to create a lightweight substructure that is stronger than steel pound-for-pound and can be structurally guaranteed for 50 years under normal designed and manufactured use.

It might be helpful, for you to follow us on a journey through the making of a Sing Door.

A Day in the Life of a Sing Door

1 STARTS WITH THE DESIGN

1 STARTS WITH THE DESIGN

The first step is the idea of the door, that beyond conceptual design is reduced to its most simplest form: The height, width, thickness of the door and the exterior material that is to be featured on the exposed surface(s) of the door.

2 SUBMIT TO SING CORE

2 SUBMIT TO SING CORE

The idea is then submitted via trade professional (possessing wholesale privileges) via our online quote request. The doors’ specifications are reviewed by our Non-warp True Flat Specialists, who can help determine what materials will be used inside the door to achieve the results expected by the end user.

If the client’s expectations include trouble-free high performance over a long life, the resulting design will be given special treatment resulting in a professional door base.

3 CREATION OF BASE DOOR

3 CREATION OF BASE DOOR

The resulting specifications are sent to Sing Core’s factory to custom assemble all the substructure components and composite materials necessary to achieve the results sought by the client.

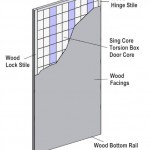

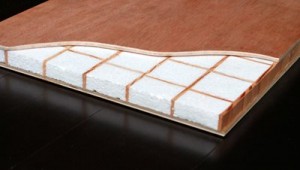

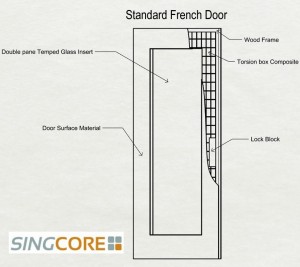

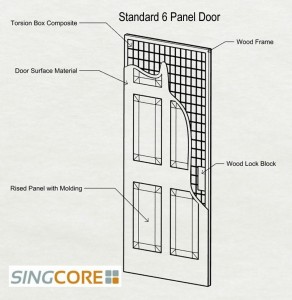

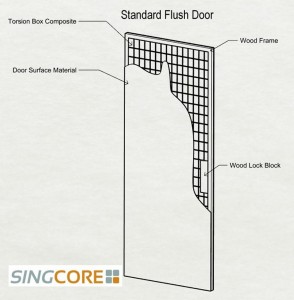

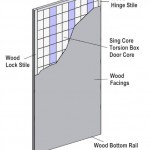

This includes interior framing, insertion of Sing’s patented torsion box core material, solid inserts, lock blocks, fusion of other inner and surface materials plus any specified lite cutouts for installation of glass windows.

4 DOOR FINISHING

After the Sing Core factory has created the base door (door blank) it is sent to the door finisher; this could be a door manufacturer, custom millwork, industrial engineers or high end craftsperson specializing in ornate doors for elite consumers.

After the Sing Core factory has created the base door (door blank) it is sent to the door finisher; this could be a door manufacturer, custom millwork, industrial engineers or high end craftsperson specializing in ornate doors for elite consumers.

The door finisher applies the final finish to the door (trimming, edge routing, painting or other finish treatment), drilling, preparing the finished door for hardware and will likely install the glass (if specified, though sometimes this is done on site depending on the project).

The door finisher may (or may not) pre-hang the door (install all hardware and attach frame).

5 DOOR INSTALLATIONS

Then the door is packed up and sent to the job site, where the attending licensed contractor installs the final door.

Sing Crowd Manufacturing

In this sense, each and every Sing Door is a crowd manufactured project; it is a cooperative effort of many individuals from concept-to-installation, without whom no Sing Door would ever be made.

So, How Can I Get a Sing Door?

The process is simple; if you are a door company or qualify for a wholesale account, you deal directly with us, otherwise, you must seek out a professional anywhere within the Sing chain who will contact us and deal with us directly and they will partner with us by submitting your request to make sure you get the best door in the world custom-designed for the high performance that you demand.

If you are seeking out a Sing Door, we know who you are; you desire only the very best and will not settle for less and we are proud to be the only door partner in the world who can help to make you a door of any size using any material and meeting or exceeding your expectations, guaranteed.

Sing door blanks are created at our factory

-

-

Door blanks

-

-

Pre cut French doors

-

-

Custom lite cut outs

Then they go to the door shop

-

-

Drill and prep non warp door blank

-

-

Holes drilled for hardware

-

-

Router for hardware intallation

-

-

Hardware installed

-

-

Installing more hardware

-

-

Preparation for glass install

Delivery to job site for installation

-

-

Paint ready with lite cut outs

-

-

Finish and/or paint doors to specs

-

-

Framing and hanging doors

-

-

Installed non warp French doors

-

-

Double custom lite doors

-

-

Custom door lite cut outs

You could be one of the best door builders by outsourcing your OEM non warping door blanks.

You could be one of the best door builders by outsourcing your OEM non warping door blanks.

Sing Core has served the building industry by providing the only Eco-friendly, insulated non-warp high-strength, lightweight door. Contractors who build Sing Homes (entire homes built of Sing products) want the added strength, stability, insulation and non-warping doors in all egress points for added safety and security.

First, we have to talk about what makes the best door in the world; it has to be:

1 Non Warp

Even the very challenging doors, large doors, sliding doors, pivot doors, all can be professional SingCore warp-free guaranteed for 50 years. The secret of the best door makers in the world is that they can use the Sing solution as their door’s base material to create a warp-free door, which is the best solution to the problem of warping doors, especially large doors which would otherwise be extremely prone to warp.

2 Lightweight, high strength, insulated and Eco friendly

The strongest lightweight door in the world is made with Sing Core inside. This revolutionary Eco-friendly building material is based on patented technology that is the best of old wood craftsmen’s technology (torsion box) and new composite technology (recycled rigid foam insulation) fused with advanced adhesives and enhanced with patent pending non-warp stiffeners. The result is an extremely lightweight panel that can span distances without deflection that has not been accomplished before in any affordable manner.

3 Easy to Install

Even the largest strongest sound deadening door can be installed in half an hour. This 500 pound Sing pivot door panel measures 10 ft. tall x 12 ft. wide x 3.5 inch thick and took less than half an hour to install in the Seattle Center for Architecture and Design.

Then, we will explain how to build the perfect door, step-by-step, showing the pictures of the entire process (even the most complicated French door, sliding door, pivot door, exterior door, etc…) with all types of skins/surface material.

How to build a patented Sing French door

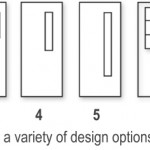

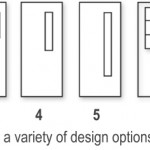

Here’s how it’s done: Purchase a Sing door panel decide on custom lite cutout design and hire a pre-hung door company or millwork to install lite, hardware, sand and finish, then deliver the resulting door to your job site or customer.

Photo Tutorial

How to create lite openings for glass installation

-

-

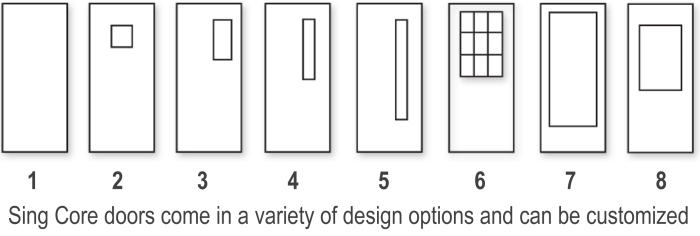

Pick a lite cutout design or create your own

-

-

-

Install glass in non warp door opening

-

-

Finish and/or paint doors to specs

-

-

-

Pre-hung large French doors ready to install

How to Get Sing Core to Build Your Best Door

- Know what you want

- Have at least an idea or drawing of what you want your best door to look like

- Determine how many and what size of panels you will need for your door project

- Know what exterior material you want on your door panels

- Decide how you will manufacture your project

- Seek out a professional

- Door Manufacturer, Architect, Designer, Design/Build, General Contractor, Mill Work, etc…

- Give them your drawing, specifying Sing Core inside

- They will deal directly with us

- Congratulations!

- You are the proud owner of the most advanced door in the world that is

- Eco-friendly

- Lightweight

- High-strength

- Insulated

- High-performance (non-warping true flat doors, walls, furniture, etc…)

- Will last longer than anything made with any other material with these benefits

Mini Large Door Gallery

The size of the average non-warp guaranteed Sing door is 9 to 14 ft tall and/or 6 to 8 ft wide.

How to build a hinged door – How to build a non warp hinge door – How to build a sliding door slab with glass – How to build a pivot door panel – How to build a flush door – How to build a carriage door