|

Pricing for Homeowners

Many educated homeowners demand that their trade professionals use Sing Core products in their home projects. (See our Homeowner’s page for more information.)

Regrettably, we are unable to provide patented Sing products for retail or directly to homeowners as we only support architects, millworks and door companies. See full apology.

If you do not have a millwork or door company in mind, please check out this online map to help find one near you.

Note: We do not sell complete finished doors to retail customers. No hardware, no finishing. We only support other trade professionals, like millworks and door companies who make doors with Sing Core inside look beautiful and perform elegantly. If you are a retail customer, please contact your architect, designer, contractor, door company or millwork and tell them you want, “Sing Core inside.”

To Get Sing Core in Your Home

- Know what you want

- Have at least an idea or drawing of what you want

- Determine how many and what size of panels you will need for your project

- Know what exterior material you want on your panels

- Congratulations!

- You are the proud owner of your new completed project that is

- Eco-friendly

- Lightweight

- High-strength

- Insulated

- High-performance (non-warping true flat doors, walls, furniture, etc…)

- Will last longer than anything made with any other material with these benefits

- Decide how you will manufacture your project

- Seek out a professional

- Architect, Designer, Design/Build, General Contractor, Mill Work, etc…

- Give them your drawing

- They will deal directly with us.

Since Sing Core is a manufacturer, we do not provide customer support for retail clients. If you are looking to build a tiny house, carriage door, etc., please seek out qualified trade professionals (such as architects, general contractors, mill-works, door manufacturers, and woodworking professionals) for help using Sing Core products for your project. Sing Core is the manufacturer of our patented invention and as such we are not qualified or staffed to teach all the uses for, or handling of, Sing Core building materials.

Sing Core does make the best reinforced structural insulated panels (RSIP) for use in applications such as walls, floors, ceilings and roofs; however, we offer no support or training or guarantee for unskilled users of Sing Core products.

For more information click Tiny House, No Permit for 800 sq. ft. Houses.

Home Owner Resources:

Take a look at some Sing Homes (made entirely of Sing products)

LEARN MORE…

SING CORE GRADES:

Sing products are available in your choice of three formats to accommodate your specifications and expectations:

Standard: The strongest, lightweight Eco-friendly building material invented

Professional: Specially formatted for non-warp performance and guarantee

Hot Press Ready: Hot-press-ready (for thin veneer)

SING CORE GRID SIZE:

Our grids come in small, medium and large sizes.

INSULATION VALUE:

R-value 3.5 (EPS foam)

R-value 5.7 (urethane foam)

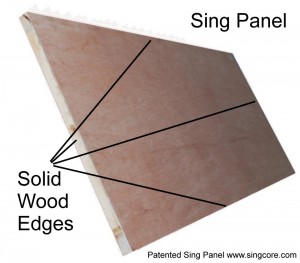

SOLID WOOD EDGE AND LOCK BLOCKS (HARD POINT):

Customizing options that can help make your order more specific are size and location of internal wood (or other specified material) such as implants, stiles and/or rails (solid wood edges on 4 sides of the Sing panel) and lock blocks or nailing for added siding over the surface of the Sing panel. The best way to show us what you need is to by provide us with a simple drawing to show the location of hard point.

SKIN CHOICE (SURFACE MATERIAL):

There are many options for Sing Core panels. (See: Material Options)

Paint Grade: 1/4 inch or thicker plywood, mdf, Masonite

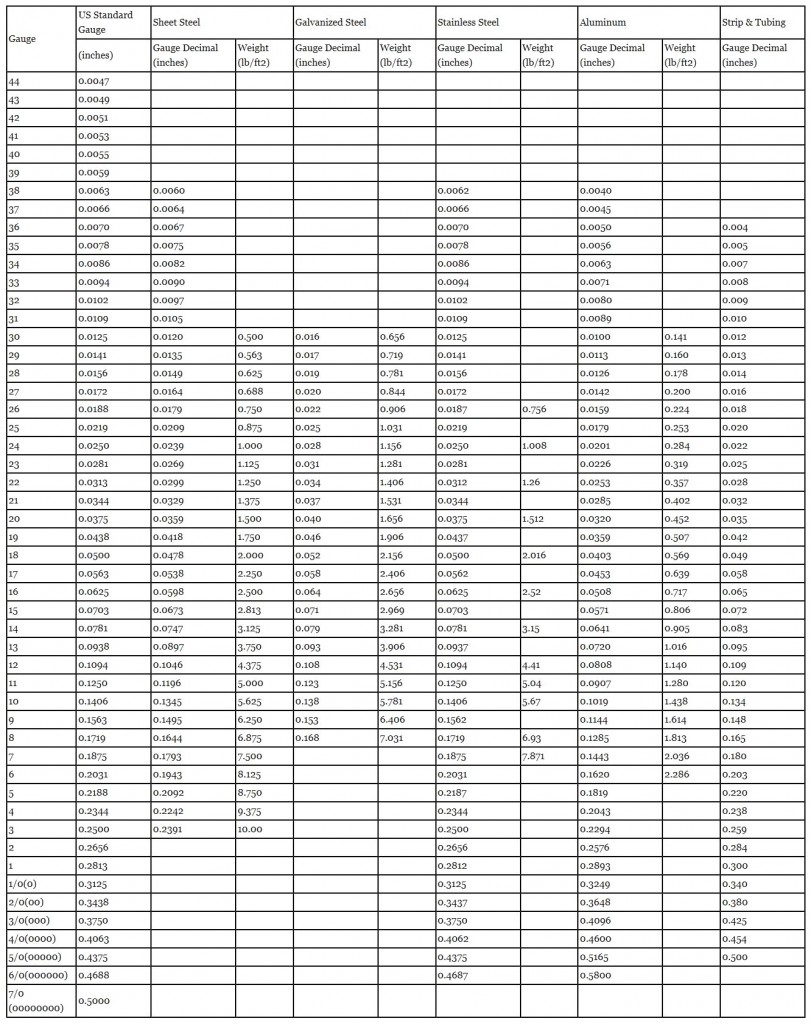

Metal: .20 inch to .125 inch aluminum, cold rolled steel, galvanized steel, hot rolled steel. HPL, FRP

Wood Grain: Thin wood veneer .020 inch on top of .125 inch mdf over top of aluminum Sing panel

Wood Stave: .125 inch applied over the top of aluminum the Sing panel substrate or on top of the .125 inch mdf over the top fo the aluminum Sing panel

Skin: There are many options for Sing Core panels. (See: Material Options)

- Paint grade panel skin

- Unfinished wood grain panel with veneer

- Wood grain with wood planks

- FRP galvanized steel

- Aluminum

- Magnesium board

- Marine grade plywood

- MDF metal

- Plastic

- Stainless steel

- Fiberglass

- Ceramic

- Concrete

Please use the work order form in the “How to Buy” section below to obtain a price quote.

WINDOW AND DOOR CUTOFFS:

Sing Core provides Sing panels with window and door pre-cut and ready for installation. We will cut 1/8 larger in width and 3/16 inch wider in length to fit your window glass. We build a frame using 1.25 inch solid wood to your specifications. You may create any size or shape of window or door with our simple method just by providing a simple drawing.

MOLDING/TRIM:

Sing Core windows and doors are profile ready for CNC routing. You may add molding or trim to create your own window or door design, otherwise we will provide you with thicker skin — such as 1/4 inch or thicker mdf, hardboard, etc. — for you to carve or profile by CNC machine. With Sing Core windows and doors you can create a true raised-panel door or any design you desire.

TRIMMED OR UNTRIMMED:

The standard ready-to-ship panel condition is, “untrimmed.” This leaves unfinished exterior edges that may have exposed adhesive and might require being built ½ inch over-sized for trimming at your location. An additional fee will be assessed for trimming and sizing in our factory. All trimmed edges are 1/2 inch over width and 1/2 inch over length. After trimming, your Sing Panel will be 1/2 inch less (4 x 8 will be 47.5 inch x 95.5 inch). Standard solid wood edging with 1.5 inch will be reduced to 1.25 inch after trimming.

SING PANELS FEATURES:

Note: Sing Core products are available wholesale only to professional trade professionals, architects, designers, design/build, general contractor, mill work, lumber yard, distributors, door reps and industries.

Best Selling

Our most popular standard product:

Sing Sandwich Core 2×4

48 in. x 24 in.

Sing Sandwich 2×4 is a 2 ft x 4 ft pre-built reinforced torsion box substrate that is 1.5 inch thick and features a lightweight plywood surface material that is easily bonded with other products. It’s universal convenient 2 ft x 4 ft size is easy to handle and transport and ships in minimum 4-piece bundle.

It’s a standard Sing Sandwich 4×8 pre-cut into 4 pieces that you can throw in the front seat of your car and turn into anything for endless applications.

The Sing Sandwich Core 2×4 is by far the most versatile Sing product to be released to the world.

Note: Sing Sandwich Core 2×4 is only available in 1.5-inch thick 2 ft x 4 ft size with lightweight plywood facings.

Minimum order $4,000 on 2×4 (48 in. x 24 in. x 1.5 in.), crate optional. For any other alteration, see Sing Panel

Sing Sandwich Panel 4×8

96 in. x 48 in.

The Sing Sandwich 4×8 panel comes in standard 4 ft x 8 ft size panels, with 1/4″ plywood skin:

- 1.5 inch

Minimum order $4,000 on Sing Sandwich 4×8 (96 in. x 48 in. x 1.5 in.). Final price includes shipping and crate.

Standard exterior surface material is lightweight plywood making it easy to apply other surface materials using standard carpenter’s wood glue and clamps.

Sing Sandwich features no solid wood edging, are unfinished and may be edge-banded to hide the visible exposed Sing Core material.

See: Sing Sandwich for more information

See also: How to Close the Edge of Sing Sandwich

The most economical way to access the Sing Core product line it to utilize our basic building material which would be our standard 4 ft. x 8 ft. sandwich panel (like the one[s] featured above). Anything else would require a custom order, please see “Custom Sing Panel” that follows.

Base price does not include shipping, crate and/or handling charges depending on quantity and stock on hand.

Custom Design Your Own Sing Panel

Like our regular custom clients you must know:

- What Size Sing Panel (the length, width & thickness) You Want

- What Exterior Skin (lightweight plywood is the default) You Want

- What Size Solid Wood (standard 1.5 inch) Edges (or specify other material)

- How Many Sing Panels (affects ship & crate cost and quantity may qualify for extra discount)

- Do You Want Untrimmed (default) or Trimmed

- How the Panel Will be Finished (all Sing Panels are unfinished)

Once you have provided the necessary information, they will be able to make sure you get the custom Sing Panel that you desire.

Regularly stocked items have a 1 week turnaround (continental USA) while custom Sing Panels have a 4 to 8 week turnaround. Since all Sing Panels are unfinished, we suggest that you contact a local high quality millwork to do the finish work on your Sing Panels to achieve satisfactory results.

You asked for it; Sing Core gives you what you’re looking for. –>

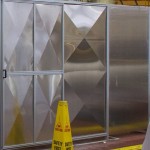

TRADE SHOW PANEL SPECIAL

Standard Professional Trade Show Panels are 90 inches tall, 2 inches thick with pre-primed HPL, available in the following sizes only:

Panel A: 30 inches wide, cam locks installed

Panel B: 24 inches wide, cam locks installed

Panel D: 30 inches wide w/door, cam locks installed

L Corner: 2 inches wide. Attaches two panels together, cam locks installed

T Corner: 2 inches wide. Attaches three panels together, cam locks installed

Special Professional trade show panels (above) are available ala carte; pick and choose what you would like. Pre-design and pick out the components you want from the above list only. Enjoy the savings.

Remember, you can create your more economical DIY trade show booth using standard Sing Sandwich panels available in convenient 4 ft. x 8 ft. size.

CUSTOM ORDERS

Custom Order or purchase Sing Panel please click here —this is only for the trade professional or qualified business-to-business and not available elsewhere at this time.

Sing Core is in the business of providing high-end true flat solutions to the most exquisite architects, designers, millwork, and industrial suppliers in the world. We only provide these services to our commercial accounts.

To obtain a custom order product (anything besides 4×8 or 2×4 Sing Sandwich) see your local trade professional, millwork and/or door company and tell them that you want, “Sing Core inside.” We can work with them to make sure that you get what you want.

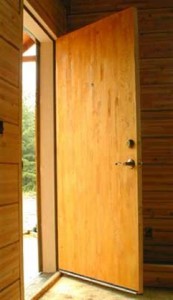

Sliding Doors for Homeowners

Imagine all the possibilities at: Sliding Door Gallery Many educated homeowners demand that their trade professionals use Sing Core products to build their dream homes. Sing Core does not make the doors themselves, but after researching our patented Sing Core materials many homeowners will not allow other building materials to be used. See our new C Series line of Affordable Barn Door and Sliding Closet Doors. (Visit our homeowner’s page.)

Regrettably, we are unable to provide patented Sing products for retail or directly to homeowners as we only support architects, millworks and door companies. See full apology.

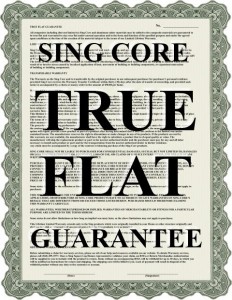

Doors are a very critical component and must withstand constant impact, use and weathering, be sound-deadening and long-lasting. The solution is our patented Sing Core materials. No matter what style doors you envision for your home, or if you need a barn door for your barn, patented Sing Core panels can build the strongest yet lightweight, long-lasting, insulated, and true flat doors. This means Sing Core doors are not dangerously heavy or difficult to use, they never warp or twist (which prevents damage to hinges and fingers), and they will last for many decades with normal use.

Doors are a very critical component and must withstand constant impact, use and weathering, be sound-deadening and long-lasting. The solution is our patented Sing Core materials. No matter what style doors you envision for your home, or if you need a barn door for your barn, patented Sing Core panels can build the strongest yet lightweight, long-lasting, insulated, and true flat doors. This means Sing Core doors are not dangerously heavy or difficult to use, they never warp or twist (which prevents damage to hinges and fingers), and they will last for many decades with normal use.

Our patented Sing Core panels are made with our patented water-resistant, formaldehyde-free, eco-friendly glue and made in the USA. If you need a sliding door for your barn, barn doors made with our patented Sing Core panels are the most long-lasting, insulated and sturdy.

Exterior sliding barn doors can be beautiful following installation, but after time, problems develop due to expansion and contraction from weather exposure causing them to warp, twist, and crack and compromising the overall performance of your sliding barn door. Even a 1/4″ deflection can compromise a barn door’s function and aesthetically pleasing quality.

Sing Core’s true flat guarantee is why high-end millworks and designers seek out Sing Core for extreme weather and temperature-controlled environments, and that guarantee will ensure your barn door works well for many decades.

To order Sing Core sliding door materials please see our pricing page.

Rush orders: within 2 business days, subject to skin material availability, with a rush charge. – See more at: http://singcore.com/sing-core-sliding-doors

InPlant Offices

Proudly made in the USA, Sing Inplant Offices are fully insulated lightweight and high strength modular office systems that help streamline plant operations. We work with architects, engineers and oplant managers to achieve the prefab results that you desire.

Your inplant office specifications determine what goes into your modular inplant office panels which are a special composite structure design to achieve the best results while coming within your budget parameters.

Patented Sing Core creates the best prefab metal buildings resulting in reduction of industrial maintenance that can be reconfigured on-the-fly to be expanded or reduced based on our unique modular technology.

Sing prefab steel buildings are a fraction of the cost of solid steel, while delivering the highest precision results for convenient control of portable buildings prices.

Your plant manager will thank us of helping create such an amazing modular inplant office system, that can be conveniently stacked and stored in between uses.

Assembly of your temporary Sing industrial building is quick, easy and painless if you use our T slot panel and/or cam lock designs.

Plant operations become more effective using sing inplant offices that can be used for anything from a guard shack or powder coating booth – to – prefabricated metal buildings or even a complete prefab warehouse.

T Slot Training Facility

Even do-it-yourselfers can get in on the economy inplant office structures made of our economical standard Sing Sandwich panels available from Lowe’s for a convenient and low cost DIY option.

Sing Core Inplant Offices are lightweight, modular, insulated and high strength

Butcher Block Table Top Gallery

- Honeycomb insulated butcher block table top

- Insulated high strength honeycomb butcher block table top

- Over-sized lightweight butcher block table top

- Insulated non warp lightweight honeycomb butcher block table top

- Lightweight portable over-sized butcher block table top

- Patented lightweight non warp butcher block table top

- Large patented honeycomb sandwich table top

- Walnut skinned lightweight honeycomb table top

Made in the USA

Sing Core is committed to our strict US made pledge.

Sing Core is committed to our strict US made pledge.

All Sing Core products are made in the USA using locally-sourced materials using sustainably honorable low energy creation processes with very little waste, and no toxic chemicals or manufacturing methods.

Many architects, designers and builders are also committed to doing their best to buy American seeking what is made in the usa.

In a time when many of the components that we use in construction and manufacturing in the Unites States are imported from offshore sources due simply to the reduced cost.

For instance, in the United States the average manufacturing job hourly rate of pay is $34.74, in comparison to China’s $1.36 per hour and even less in India (according to the BLS) making it extremely difficult not to be seduced by offshore’s cheaper materials.

According to Sing Core inventor, Peter Sing, “It is difficult to compete with imports, but we know that people want high quality and something that will last for lifetimes; not like disposable cheap imports.” Yet, many Sing Core products are actually exported outside the USA.

Given a choice between a product made in the U.S. and an identical one made abroad, 78 percent of Americans would rather buy the American product, according to a new nationally representative survey by the Consumer Reports National Research Center.

In these tough economic times, Americans are starting to join the Made in the USA movement. American businesses and the US citizenry are making it a point to demand American made products and materials.

“We are committed to bringing pride back to the phrase, ‘Made in America’,” says Sing. There was a time when ‘American made’ was synonymous with high quality, “and we’re putting America back to work, starting right here…” and empowering other Americans to join our growing number of crowdsourcing manufacturers.

“We are committed to bringing pride back to the phrase, ‘Made in America’,” says Sing. There was a time when ‘American made’ was synonymous with high quality, “and we’re putting America back to work, starting right here…” and empowering other Americans to join our growing number of crowdsourcing manufacturers.

We are seeing a grass roots revolution in American made manufacturing. As jobs are on the decline, we are seeing individuals with basic woodworking skills and craftsmen taking charge of their economic destinies by birthing bootstrap operations. “We’re helping people start their own manufacturing facilities at home,” and all you need is as little room as a single car garage to start.

There is a huge movement to manufacture green, sustainable building materials and products locally.

Imagine being able to get locally made building products or furniture with Sing Core as the base, making your American Made end products not only Made in the USA, but also green and sustainable, making the world a better place.

Sing Core has created a ripple effect that affects the local economy and grows to affect the national economy as they create jobs including supporting local drivers, shipping and packaging companies, as well as helping craftspeople replace lost income due to downsizing, or our declining fiscal outlook.

In a time when just one full-time income-earning American supports five other jobs in the United States, Sing Core is recycling an economic impact through our economy and creating more jobs for Americans

SING CORE METAL SKIN OPTIONS

Finished Sing Core panels are composed of a patented Sing Core honeycomb/torsion box made with our patented formaldehyde-free glue and R3 insulated foam enclosed in the outer skin of your choice.

2-8-1 Sing Aluminum

|

– See more at: http://singcore.com/product/sing-composites/sing-core-metal#sthash.sCNEnc6t.dpuf

Sandwich Panel Applications

Sandwich Panel Substrate Method & Applications

Experience the wide range of applications for different styles of functionality and the exiting creative ideas that multiply the expansive ways that the Sing Sandwich Panel can be used as substrate.

For instance using the “drop-in method,” you can cut or rip your Sing Sandwich into substrate material to be the core value of any product that you like, increasing the effectiveness of your design or end-product with now becomes:

- More dimensionally stable

- Lightweight

- Stronger than steel pound for pound

- Durable and long-lasting

- Eco-friendly

The resulting wood panels made in your shop or by the do-it-yourselfer can be used in many ways, to make:

- Butcher Block

- Counter Tops

- Doors

- Shelving

- Stairs

- Staircases

- Table Tops

- Trade Show Displays

- Wood Ceiling

- Wood flooring

- Wood plank walls

- Wood Siding

- Wood Scaffolding, etc… (see photos below)

The applications are virtually unlimited!

Here is a visual example of our DIY drop-in method using Sing Sandwich Panel as substrate material:

|

|

|

|

|

|

|

|