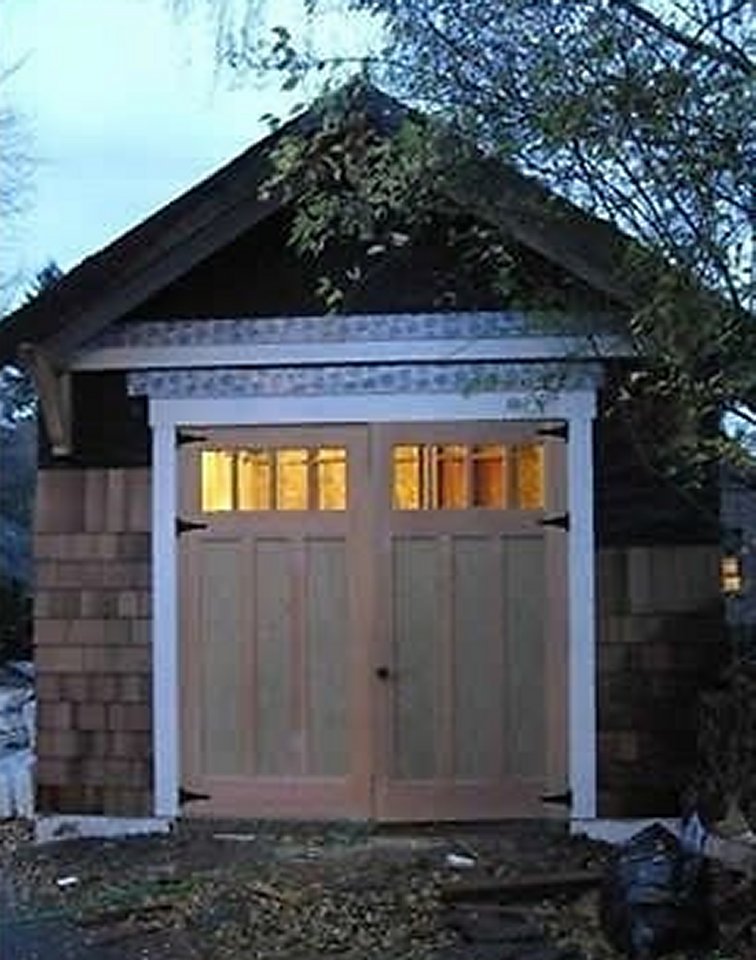

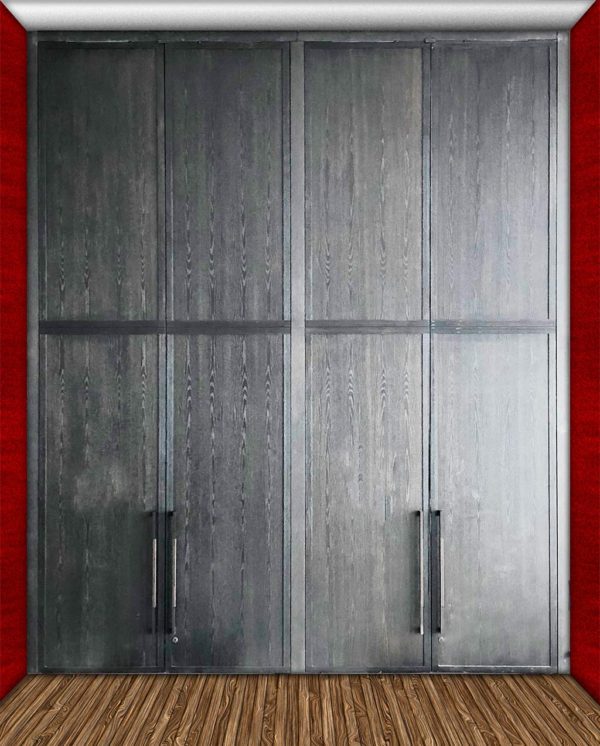

A pivot door rotates on a pivot box in the floor and the top jamb rather than traditional door side hinges, which is common in most homes. Pivot Doors have become a popular choice for entrances, creating a bold statement at your first point of contact.

What makes pivot doors so unique? The pivot door or pivot window is an opening system with a central or lateral rotating axis that allows for very large door panels. The craftsmanship and technology of a pivot hinge allows for a larger opening than most other types of doors since traditional hinges cannot carry the same kind of weight. Pivot doors are fantastic options for where there is a large amount of space and enough floor room for the door to be able to swing all around.

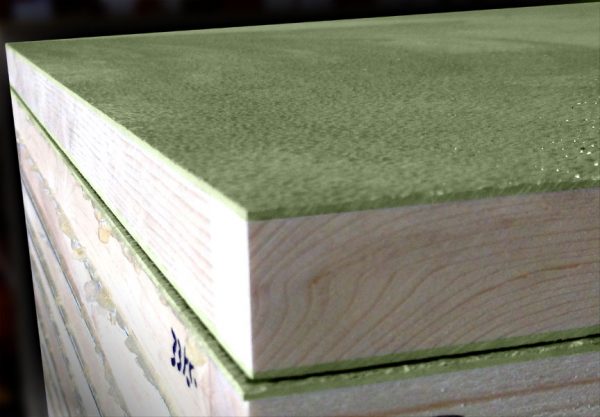

Grounded in the principles of modern architecture, a pivot door emphasizes clean lines and simple shapes. Pivot doors are well suited for pivoting walls and can also be used as room dividers. Until now, affordable pivot doors are thicker than average doors and heavy in weight. The large size and heavy weight causes extra costs associated with shipping and handling. Shipping is more expensive because shipping costs are calculated on weight. Handling is more expensive because heavy equipment is necessary for transporting and manipulating the pivot door into place for installation. Pivot door hardware is also based on the affordable pivot door’s weight, so a heavier pivot door will require more expensive and heavy duty hardware. Here at Sing Core we manufacture custom premium wood pivot-hung entry doors for exterior and interior use. Our pivot doors feature our patented lightweight insulated torsion box pivot door core inside. Which imbues each door with the unique characteristics of a solid core pivot door featuring the exact size, material and appearance of any style of pivot door, while remaining extremely lightweight and incredibly strong. Independently University tested at 660 PSI, makes Sing Core’s pivot door core stronger than steel pound for pound. The pre-insulated core also means greater climate control and noise cancellation between spaces. Also, the lightweight of Sing Core’s pivot doors, means less shipping, handling, transportation and installation costs, requiring less expensive hardware.

A pivot, not a hinge rather than hanging from hinges in the frame, a pivot-hung door swings on a set of pins mounted in the top and bottom of the door. Transform the look of your home or office by opting for Sing Core’s affordable pivot doors. Pivoting front entry doors provide an elegant look and appear to float inside the door frame. We are offering premium wood pivot-hung entry doors for exterior and interior use that cannot be found anywhere else. Let Sing Core build your custom pivot doors, custom modern entry doors, exterior mahogany wood doors, or any other custom door you can imagine! If you can create the idea, we can create the door. Every Sing Core door comes with a 50 year structural guarantee, something that no other door company has been able to offer.