Dictionary

What has been built with Sing Honeycomb Panels?

Sing Panels are versatile. The applications are virtually unlimited. They have been built into: doors, sliding doors, pocket doors, bi-fold doors, museum display walls, movable walls, stage floors, portable floors, mezzanine floors, clean room floors, posts, beams, trade show panel, dressers, armoires, bedframes, floors, ceilings, stairs, tables, benches, cabinets, pallets, Tiny Houses, and log homes. Shop for Sing products in our online store. You may custom design your products and fill out our Work Order to get a fast price quote.

Take Sing Panels to build your own new product lines and promote lightweight, long lasting, Eco-friendly products; take a positive action to make the world a better place to live.

Nearly Limitless possibilities

With so many design options of Sing Core products the ideas are nearly limitless. Click here to see just some of the ideas that have been used with our products.

Aluminum Panels

Aluminum honeycomb panels, aluminum honeycomb panel price, honeycomb aluminum sheets, Aluminum Decking, aluminum honeycomb panel, honeycomb aluminum sheets, aluminum panels for trailers, aluminum composite panels, aluminum panels for art, aluminum patio roof panels See: Aluminum Panels Photo Gallery

Architectural Applications

Ceiling panels, custom shapes, large custom panels, curved honeycomb panels, false beam, sign graphic displays panels, Signage, self adhesive surfaces, sandwich board panel, sign display, dry erase board, sandwich board, outdoor sandwich board, trade show crate, booth panels, sign panels, pool covers for swimming pools, & Jacuzzi cover industry. Shelving, lightweight strong shelf, long span shelf, garage warehouse shelving, industrial strength shelving, storage shelving rack, garage work table, bench, heavy duty shelving, garage storage rack, inlay work, exotic hardwood, and fine veneer butcher block, chopping block, stainless work table, counter top. See: Architectural Application Photos

Bench

Park bench, school bench, church bench, hospital bench, shop bench, aluminum bench, metal bench, lightweight bench, interior bench, exterior bench, weatherproof bench, outdoor bench.

Bi Fold Doors

Industrial bi fold doors, schweiss bi fold doors, large bi fold doors, industrial sliding doors, building a sliding garage door, express bi fold doors, wickes bi fold doors, bi fold doors lowes, eurocell bi fold doors

Boat and Marine Industry

Boat builder supply material, marine panel, marine bulkheads.

Building Materials

Bamboo stair treads, hardwood stair treads, post, beams, lightweight plywood, lightweight trusses, ceiling decoration, plank beam, work platforms, equipment enclosures. Honeycomb lightweight torsion box sandwich panel, balsa wood, plastic honeycomb, tricell paper honeycomb, paper honeycomb panel. Aluminum nomex core, divinycell, dura composite. Balsa wood door, hurricane panel, honeycomb core, paper door core, panel core, core panel, door core honeycomb sheet, creative aluminum honeycomb panels, lightweight panel solutions, aluminum honeycomb test panels, end grain balsa wood, balsa wood blank, balsa wood plywood, paulownia lumber, basswood.

Building System

Clean rooms, digital x-ray systems, modular implant building tiny house, small cabin, small house, post and beam structure, CMM rooms, cold storage rooms, controlled & critical environments, interior and exterior cladding, panel house, tiny house on the trailer, tea house, garden shed, pole barn, garage, tiny house design, prefab pump house, ice fishing house, hunting cabin, refrigerate truck body, Johnson refrigerated truck body, lofts , loft design idea, conversion warehouse, factory loft, shipping container, honeycomb panel enclosures clean room floor, walls and ceilings.

Door

Specialized Doors, Balsa wood door core, panel core, core panel, door core suppliers. garage door supply, garage door part supplier, garage door installation and repair service. Overhead carriage door, sliding door, cold storage sliding door, sliding door hardware, sliding barn door, movable wall, truck door, sliding door track. Book shelves, exterior door, entry door, interior door, pocket door, wall panel, moveable wall room divider, flush door supplier, solid wood door, solid core door, carriage door, overhead carriage door, sectional garage door, garage window insert, canopy, garage door, warehouse door, cold storage door, sliding door mfg, sliding hardware, kitchen cabinet door, closet door, hollow metal door, aluminum sliding door, stainless sliding door, folding, pocket sliding door, sliding door hardware, sliding gate mfgs, hanging sliding door, church door, large industry door, hangar door, particle board door core, hardwood door, solid wood door core, lvl door core, mdo mold door, aluminum bench, chi distributors, truck overhead door, pivot door, walk in freezer door, industry sliding door, residential sliding door/system, pocket door track, wood carriage door, wood garage door, hurricane door, front door solid wood, solid cedar barn door, solid wood pocket door, solid wood sliding door, panel sliding door, sliding doors, solid wood bookcases, sliding cupboard door, sliding wardrobe door, sliding closet door, solid core wood door, honeycomb door core, flush door, slab door, slab door solid core, hollow core door, door parts, sliding door guide, sliding wood, barn door, custom door particle, board door core, mineral core, stainless door, steel door, closet door, folding door, v.t. industries architecture wood door, lightweight pantry door, oversized large doors, cellar doors, roof hatch, access panels, wine cellar door, home security door.

Elevator

Elevator panels, elevators.

Floor

Flooring, moveable floors and covers, walk ways and platforms, step platform. platform floor substrate, insulated floor, garage floor, basement floor, portable floor, raised floor, commercial raised floor, basement sub floor, mezzanine floor, timber floor, loft floor, beam floor, storage floor, dance floor, folding raised floor, clean room floor, factory loft floor, outdoor decking, lightweight decks, patio, pergola, tent flooring, outdoor wedding flooring, outdoor flooring, garden show walkway, plant nursery display area, ice arena, beach flooring, outdoor special event flooring, home gym flooring, heavy equipment runways, temporary roadway, raised decking, leveled flooring, concert flooring, trade show flooring, fitness club flooring, sports flooring, trade fair grounds, exhibition flooring, disco floor, adventure catering floor, temporary basement flooring, special event flooring, temporary wheelchair ramp.

Floor and Stage

Portable stage, portable floor, stage floor, portable stage floor, choir riser, mezzanine floor, loft floor, raised floor, commercial raised floor, lightweight floor, movable floor, movie theater screens, large digital displays

Furniture

Kitchen furniture, kitchen, hutch, hoosier kitchen cabinet, base cabinet, wall cabinet, cabinet door, island, island counter top, butcher block kitchen island, micro wave cart, cutting board work bench, utility cart, island cart bed room furniture: 3 drawer dresser, 5 drawer dresser, dresser with large drawer, deep drawer, collapsible dresser, captain platform bed, nautical skipper bed, custom bunk bed, stackable loft, collapsible storage box storage bed, hideaway bed, bookcase bed, cabin bed, cabin bed with cabinet desk and book case, wall bed, cabin bed with desk, cabin bed with build in wardrobes, H 155 x w 94.4 x L 194 cm (61.02 x 37.16 x 76.37), platform bed 54″ x75″ x 10″ lightweight shelf, book case, collapsible carcass, cabinet maker.

Honeycomb Composite Panels

Honeycomb sandwich panel, marine honeycomb panels, marine composite panels, stock honeycomb panels, honeycomb core, honeycomb panels for sale, cardboard honeycomb panels, honeycomb core material, honeycomb building material, honeycomb material properties, honeycomb material aluminum, marine honeycomb panels, marine composite panels, stock honeycomb panels, honeycomb sandwich panel, honeycomb panel manufacture.

Plastic honeycomb panels, fiberglass honeycomb panels, FRP honeycomb panel, Manufacturer FRP Panels, How to Install FRP Panels, FRP Ceiling Panels, Smooth FRP Panels, plastic honeycomb material, pp honeycomb core, frp honeycomb, frp honeycomb sandwich panel, frp honeycomb product, fiber glass supply, frp door, trailer, exterior fiberglass entrance doors. Frp beam, frp honeycomb beam, frp beam connector, post connector.

Industrial and Material Handling

Mezzanine rack, material handling, display rack, industry rack, shelving unit, wall shelf, shipping container, heavy duty pallet, oversized heavy duty pallet, industrial shop cart on wheels, industrial load wood shelving cart, service cart with cabinet, car ramp, utility trailer ramp.

Lightweight panels

Lightweight panel, Lightweight Composite Wood Panels, Lightweight Plastic Panels, Indoor Faux Stone Panels Lightweight, Lightweight Panels Foam Core. Lightweight Panels Plywood, Lightweight Slatwall Panels

Pools

Swimming pool cover, hot tub cover, lap pool cover, moveable floors and covers.

Restaurant Institution Furniture

Table desk restaurant table, top legs, wood table top, folding table.

Sandwich Panel

Carbon fiber sandwich panel, sandwich panel mfg, sandwich panel walls, sandwich panel suppliers, sandwich panel manufacturers, sandwich panel roofing, sandwich panel for sale, sandwich panel design

Room Divider

Apartment room dividers, movable room divider ideas, ikea sliding doors room divider, sliding room dividers ikea, glass room dividers ikea, ikea pax doors room divider, ikea hack room divider, ikea hack sliding door

Sliding Door

Sliding doors, sliding barn door, exterior sliding door, interior sliding door, sliding closet door, industrial sliding doors, industrial garage doors, commercial doors, steel doors, roll up doors, industrial exterior doors, industrial glass doors. Exterior sliding barn door, exterior sliding door hardware, exterior sliding door hardware kits, exterior sliding door systems, exterior sliding door hardware barn, exterior sliding door track hardware. Interior sliding doors, sliding barn doors interior, sliding doors exterior, sliding doors interior ikea, sliding doors interior, sliding doors interior design, sliding doors interior track, sliding closet doors, wall slide doors

Sliding Glass Door

Interior glass door, interior glass wooden door, solid wood frame door, stainless steel door and frame, wood frame glass door, wooden glass door, frosted glass interior door, steel glass door, modern glass door, modern wood door, sliding glass door, modern wood glass door, wood frame sliding glass door, modern large glass door, glass sliding door with wood frame, sliding wood door, contemporary wood door, modern single wood door, interior wood sliding door, sliding door design.

Tables and desks

Drafting table, metal table, banquet tables, folding table, table top, heavy duty table, table base, table leg, outdoor table, bbq post and beam structure.

Tank

Liquid transport tank, water storage tank, portable water tank, fiber glass tank, aluminum tank.

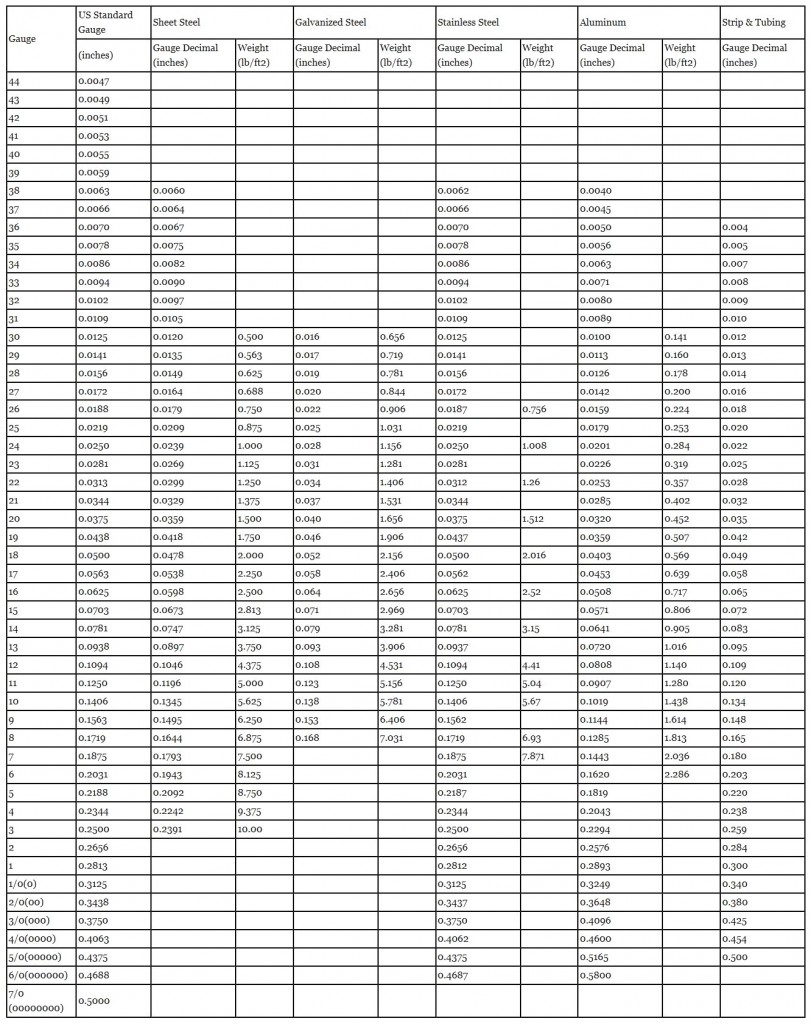

Technical

Clean room walls, cleanrooms, cold storage rooms, controlled & critical environments, digital x-ray systems, equipment enclosures, inspection rooms, laboratories, machine enclosures, nano technology, reflector panels, sporting electronics.

Torsion box

Shelf, shelves construction work table, assembly table, bench, table platform, construction, grid, router table beams, work bench top, door, honeycomb plywood, desk, wall shelving, bracket shelving, modular shelf, wall mount book case, block wall shelf, spine wall shelf, s wall shelf, box shelves, floating shelf, torsion box shelf, torsion box bench, torsion construction, torsion box honeycomb, wood torsion box, sandwich torsion box, sandwich sing core, sing sandwich panel, super sandwich panel.

Trade Show

trade show booth, display booth, panel display booth system, panel display board system, display cases, display tables, display booth flooring, display booth furniture, display booth walls, slatwall, trade show booth furniture, trade show booth walls. Tradeshow booth wall panels, tradeshow booth wood flooring, tradeshow booth wall system, display booth wall panels, display booth wood flooring, display booth wall system

Transportation

Truck/trailer doors, Truck bed, trailer bed, truck door, van truck wall, roof, van trailer, cover box van, enclosed trailer, box trailer, RV panels, train floor, rail floors, car ramp, aluminum lightweight trailer, covered trailer, box trailer, utility trailer ramp.

Veneer Laminate Industry

Veneer substrate. Veneer mfg, suppliers, vacuum door skin architecture panel vacuum table. Veneer suppliers, Brookside veneer, exotic veneer faces, custom laminate, the woodworking and laminating industries, door-sized faces of exotic veneer, edge banding, furniture and panel manufacturers, thick edge bandings, substrate materials. Exotic flitch stock, flitches, exotic paperback, architectural grade veneers, paperback veneer, polyflex.

Wall

Folding wall, portable room partition, movable wall panel, moveable wall, partition wall, room partition wall, room divider sliding door, portable wall, curtain wall panels, portable room, clean room walls, toilet partition, toilet partition parts and hardware, bath room stall, hufco partition wall, modern fold. Museum, museum artifact display tables, art panels, wall signage, system, signs, showcases, shelf, display/museum. Assorted art museum, art curators, museumusa.org, exhibit designer, tech provider, pedestal display, panel display art display, art stand, pedestal showcase and stand, display pedestal store floor fixture, lightweight slatwall, store wall fixture. Store fixture, custom counter and showcase, display show case wall showcase and tower, pedestal show case and stands, custom wall cabinet, store fixture display case slat wall gondola shelves, free standing shelf unit, traveling museum, traveling exhibit mobile museum furniture, hanging hook clamp lamps brackets image graphic digital solutions for large format graphic, art gallery supply, studio display, trade display, museum exhibit design, museum display supply, stand design, case product, wood display case cabinet. Lightweight display, trade show display wall shelf sculpture stand, art hanging system, museum resource art organization, museum marketing. Museum vendor, museums USA.com, access, canvas for museum panel, fixture panels, airports art, trade show store fixture display, retail store fixture displays, retail store fixture tables, free standing wall, free standing partition wall, free standing museum wall

Wood Working Shop

Lightweight strong panels for cold press, lightweight true flat, cold press beam, cold press panel, vacuum table, torsion box router table, torsion box work table, torsion box work bench, super large storage pallet, lightweight large dunnage, utility cart, heavy duty lightweight shelf, plywood storage rack, lumber storage shelf, machinery enclosures, marker board panels, solar collector panels, architecture components, gang plank fixturing panel, insulated header, impact attenuation panel stiffener panel work platforms.

Marketplace

Aerospace, Agriculture & Forestry, Airline, Art Supplies, Arts and Crafts, Backyard Poultry Supplies, Bath, Bedding, Boats, Business & Industrial, Businesses for Sale, Campground & RV Parks, Camping, Cars & Trucks, Construction, Crafts, Cruise Ships, Dog Supplies, Electrical & Test Equipment, Electronics, Entertainment, Exercise & Fitness, Farm and Garden, Fish & Aquariums, Food & Beverages, Fuel & Energy, Furniture, General, Greenhouse, Handcrafted & Finished Pieces, Healthcare, Lab & Life Science, Heavy Equipment, Heavy Equipment Attachments, Heavy Equipment Parts & Accs, Holiday & Seasonal Décor, Home & Garden, Home Arts & Crafts, Home Décor, Home Improvement, Horse Supplies, Household, Hunting, Indoor Games, Kids’ Crafts, Kitchen, Dining & Bar, Light Equipment & Tools, Lodging, Luggage, Luggage Accessories, Manufacturing & Metalworking, Materials, Motorcycles, MRO & Industrial Supply, Multi-Purpose Craft Supplies, Office, Other, Other Crafts, Other Vehicles & Trailers, Outdoor Sports, Packing & Shipping, Parts & Accessories, Party Supply

Pet Supplies, Powersports, Printing & Graphic Arts, Rail, Religious Products & Supplies, Reptile Supplies, Restaurant & Catering, Retail & Services, RV, Solar, Sporting, Sporting Goods, Team Sports, Tools, Transportation, Travel, Travel Accessories, Water Sports, Wedding Supplies, Wholesale Lots, Window Treatments, Winter Sports, Wood Working Machines, Yard, Garden & Outdoor Living

Sing Core Attributes

Lightweight, Honeycomb, and Sandwich