Common FAQ|Doors|Trade Show Panels|Tinyhouses|Log Homes

Sing Trade Show Panels FAQ

What makes Sing cores different from paper honeycomb trade show panels?

A: Our trade show panels use recycled eps foam and our patented vertical grain grid system, which provides much more strength and is as light/lighter than paper honeycomb.

How can I get Sing trade show panels?

A: There are three ways to order Sing trade show panels, 1) Order one or more pre-congfigured trad show display kits (easiest way, buy with one-click). 2) Build Your Own Booth. Create your own DIY customized trade show display kits using patented Sing Core trade show panel kit components, or 3) Create your own custom trade show display design and we build it to your specs using patented Sing Core inside (requires drawing).

What makes Sing cores different from paper honeycomb trade show panels?

A: Our trade show panels use recycled eps foam and our patented vertical grain grid system, which provides much more strength and is as light/lighter than paper honeycomb.

How much is a custom trade show drawing?

A: If we create the drawing for your custom trade show display the cost is $60, whereas if you attach your drawing (your drawing doesn’t have to be professional, it could be simply sketched on a napkin) to your quote request form, there is no charge for the drawing. The reason we require a drawing is so that we can know the basic shape of your structure which will help us to better quote your trade show display.

Can our company purchase only the Sing Core to make our own trade show panels?

A: The different options of our Sing Core and Sing Core Panels and our Sing Trade Show Panels allow you to decide how you want to work with our technologically advanced core material. You can choose how much or little work you want to apply to the core*. (*when applying skins you will need to use a cold-press method)

- Purchase just the core, you would then apply the skins on both sides and solid wood edging* (*place edging before apply top skin) or

- Purchase core with skins* (*birch or luan) and apply the edge-banding yourself or hire someone to do it

- or

- Purchase the core as an all in one component* (core, skins [birch or luan ] & solid wood edging)and receive your panels complete, just paint/seal and finish as you desire and install hardware.

How strong are your museum panels?

A: Our Sing Trade Show Panels 4’ x 8’ x 1 3/8 standard trade show panels can support the weight of 4 people between 2 saw horses with no other support and with negligible bending.

Are significantly more water resistant than paper honeycomb museum and trade show panels.

Our Sing trade show panels come with a 10 year limited structural warranty. Limited warranty

How light are your Sing trade show panels?

A: Our Sing trade show panels are at least one-third or more lighter in weight.

How much do your Sing cores, Sing panels and Sing trade show panels cost?

- That is an excellent question and one that cannot be answered here on our Q & A page as our pricing depends on a number of factors

- Do you want Sing Cores only, Sing Core Panels or Sing Trade Show Panels?

- How many would you like to purchase?

- How thick would you like the panels to be?

- Please email us your questions and we will respond within 1 business day.

What types of material can I laminate to Sing Core?

A: Any substrate (skin) that is capable of carrying a load.

How do you ship?

- LTL Freight Company – common carrier,

- Arrange for pickup by your preferred carrier

- Customer pick up from our facility here in McCleary, Washington

What is your lead time?

A: Usually four to six weeks, but this has been known to extend out to five or more weeks on occasion. For our regular contract customers, we block out production time for them and for others we will “work with them” as our production schedule allows.

How does my company become a “Regular Contract Customer”

A: You can become one of our “Regular Contract Customers” by entering into a contract to order at least 50 cores per month with our company (this allows you to receive better discounts and reserved production and shipping times)

What size are your panels?

- We can manufacture panels up to 20’ x 50’. However, the most commonly ordered size is 4’ x 8’* (*finished size is 47” x 95”) and are usually determined by the size of the skins available. Sizes are limited somewhat by shipping company restrictions as well.

- We also offer oversize Sing trade show panels, these would be done in 4’x8’ sizes and then you would attach using biscuit joints

How do we assemble a large Sing trade show display?

- We will ship your trade show panels in crates to ensure their safe arrival.

- Our largest panel can come 12’ x 10’, but you can combine these to make almost any size trade show wall you desire.

- Once your trade show panels have arrived, take the panels to the room they will be assembled in and do the following:

- 1st: arrange your panels either on the ground or place on platform but ensure that it is being assembled on a level plane so that they can be joined precisely.

- Next, join the panels in the horizontal position using our biscuit joints and applying glue in the grooved “biscuit” cut, then insert biscuit joint to one side of panel, apply glue to groove in second panel that will be attached to the first panel, slide panel so that the other half of biscuit is inserted into the biscuit groove and allow all glued areas to dry completely.

- Once all of the panels have been assembled together to make your oversize wall and glue has completely dried you may then lift and begin installing your wall with your hardware

- “Call us if you have any questions/concerns on how to install our Sing trade show wall panels” 360-459-3577

How much pressure to I use to apply skins myself?

A: Enough for intimate contact with our Sing Core with or without solid wood edging but too much pressure can cause damage to the core.

Do you have distributors?

A: No, at this time everything is sold directly by us from our manufacturing location in McCleary, Washington.

Do you keep any panels in stock?

A: All of our Sing Cores, Sing Panels, & Sing Trade Show Panels are made to order for each of our customers.

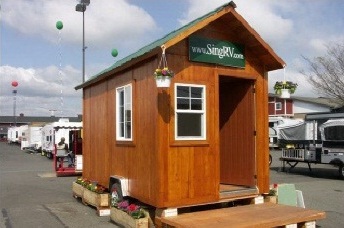

It’s so easy to use Sing Panels to make beautiful

It’s so easy to use Sing Panels to make beautiful

/dsc_0191_ew7m.jpg)

/dsc_0194.jpg)

/dsc_0199.jpg)