Exterior French doors are all the rage because if they’re done right, they offer superb safety and security while being Eco-friendly, lightweight, and fully insulated for increased sound deadening and climate control. The only way to create a sustainable lightweight pair of large double front doors that possess these double French doors exterior characteristics, which are also stronger than steel and guaranteed not to warp for 50 years, is with Sing Core inside.

Why is Sing Core so important for the most particular door afficionados in the world?

Granted doors with Sing Core inside may not be necessary for the masses, as standard doors available in standard door sizes are less expensive and adequate for normal everyday use. “Normal” doors move. The AWI standard for a normal 3-0 7-0 door is one-quarter-inch of movement, and the normal door industry from the door manufacturing companies, the hardware industry, and installation contractors all follow the guidelines of allowing a quarter-inch of movement without affecting normal door operation.

FRENCH DOORS

While you may think that glass is fairly stable, the frame which holds the glass (the French door) is subject to movement. It is the unforgiving glass which makes French doors more prone to failure, for if one corner is the slightest bit out of plum, the opposing diagonal corner will stick out like a sore thumb.

DOUBLE DOORS

Multiply the potential for failure times two, if you have two times the doors. A double door, two doors side by side, can potentially have uncooperative movement, even in normal-sized doors of 7 ft heights, double doors can have up to one-half inch of potential movement and still not be considered officially as warped doors, yet this exceeds the efficacy of the hardware, rendering the double doors inoperable.

EXTERIOR DOORS

To further complicate the problem with door movement over the life of a door which is more likely to move more often according to changes in the environment, and even more so, if one side of the door faces the structures interior and the other is exposed to the elements. This is the recipe for the perfect door disaster. That is why interior doors cannot be used as exterior doors. Exterior doors need to be made to different specifications to maintain the same “normal” quarter-inch movement allowed.

DOUBLE FRENCH DOORS EXTERIOR

As you may have guessed, by putting all these elements together in one set of doors, you have the makings of the greatest numbers of challenges associated with a single point of entry. Incredibly special attention should be in place when considering double French doors in an exterior front door application.

DOOR MATERIALS

While French doors may look like there is little at risk of compromising your egress point, there is much to take into consideration as each of the materials used in the construction of your exterior French doors has its own unique set of challenges as in integrates with the glass and its response to changes in environmental surroundings.

BIG DOOR PROBLEMS

The biggest problem with the door industry is with size. Normal movement of a door may be tolerable in a door that is 7 ft tall but once the door exceeds the 7 ft height, the rate of movement increases exponentially. The biggest problem with bigger doors is this increased movement which is referred to as door warp.

THE BIGGEST DOOR SOLUTION

Solving the problems associated with double French doors exterior is not a one-size-fits-all solution. Inventor Peter Sing’s patented and patent-pending door technologies are changing the way door are made around the world, and his True Flat Team is prepared to take on any unique and challenging combination of sizes, styles, and materials.

WHO TRUSTS THE SING SOLUTION?

The largest door companies in America trust Sing Core with their modern double front door solutions to provide their customers with the best in high-end double French doors exterior or interior, especially if they are very large in size, and they are backed by the best guarantee in the door industry: 50-years of flawless service.

50-YEAR GUARANTEE

Double front doors made with Sing Core inside can be guaranteed not to warp, bend, twist, or otherwise fail for 50 years, including full structure warranty and guaranteed not to delaminate. 50 years! No other door company can do that.

SUSTAINABILITY

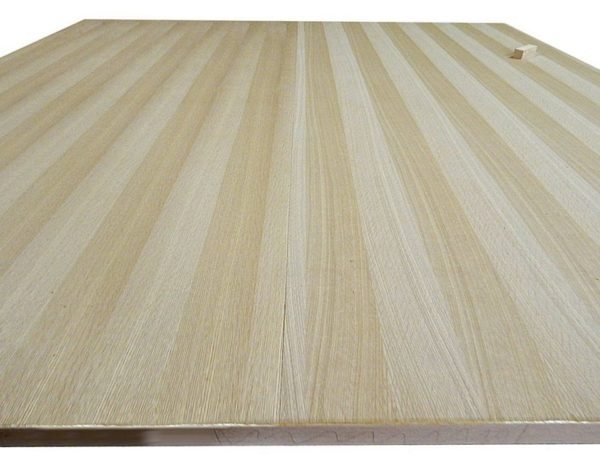

No other lightweight Eco-friendly exterior double door promises flawless longevity like Sing Core, and while it is lighter in weight than other solid core doors, Sing’s patented core is high precision (+/- .0006-in. tolerance) and stronger than steel pound for pound.

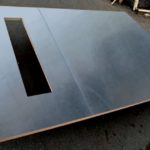

SingCore specializes in producing the highest quality sliding garage doors on the market. Our patented and patent pending core material is ultra-light weight yet super strong. Choose any style of door, skin material, or hardware arrangement that you desire. We building custom door panels to match your specs exactly.

SingCore specializes in producing the highest quality sliding garage doors on the market. Our patented and patent pending core material is ultra-light weight yet super strong. Choose any style of door, skin material, or hardware arrangement that you desire. We building custom door panels to match your specs exactly.