Working hand in hand with architects, door engineers, designers, millwork shops, and custom door manufacturers is everyday life at SingCore, nestled in the Pacific Northwest. This is where architectural flush wood doors move from idea to reality.

Yes, architecturally inspired flush doors can be purchased off the shelf. But an authentic architectural flush wood door is something entirely different. It is purpose-designed, custom-engineered, and created for a specific place. It carries intent, proportion, and material choices that cannot be replicated by standard production doors.

An architectural flush wood door may be one of a kind, or it may be part of a larger vision requiring hundreds of perfectly matched doors. Either way, each door is made for its environment, tied directly to the architecture it serves, and unmistakably specific to that project.

Architectural doors are functional art. Much like artwork on a wall, reproductions exist, but they lack the depth, precision, and presence of an original. To a trained eye, the difference is immediate.

Some clients simply won’t accept anything less than the original.

Architectural flush wood doors are comprised of many materials combined in unique ways to create a unique door that is unlike any other. An architectural door designer might mix different wood grains in a unique design pattern on the flush door’s surface to create such an individual work of art.

The architectural door artist may also combine different materials into the door’s design, such as, wood, metal, and glass. Other materials, such as aluminum, brick, cement, copper, fiberglass, hot rolled steel, laminates of all varieties, plastics, and stainless steel, just to name a few of the most popular.

The best architectural flush wood door is a composite of many materials, and nobody know the intricacies of precision bonding many different materials together, all working in unison of the whole, all the (and here’s the kicker) while,

Remaining Perfectly Straight for 50 Years

than inventor, Peter Sing, who provides his patented and patent-pending architectural flush wood door technologies which are revolutionizing the way architectural doors are made.

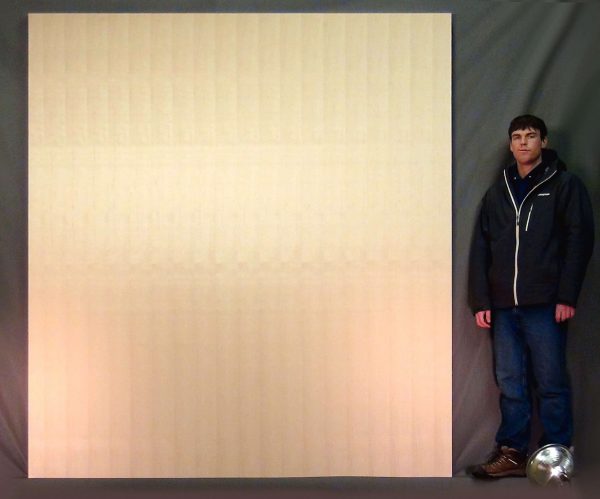

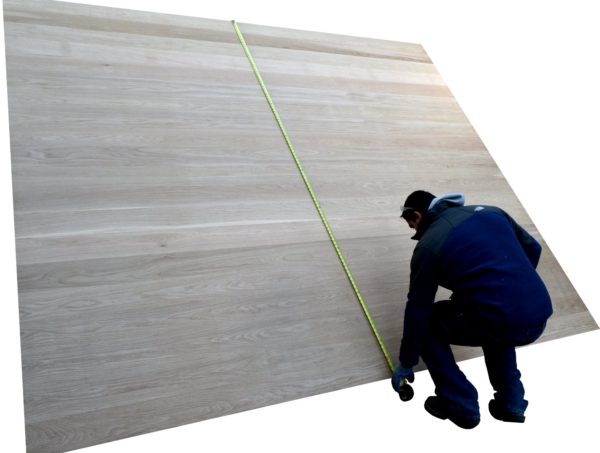

The biggest and best architectural wood doors are large oversized flush architectural grade commercial doors, that can be very large, up to 50 ft tall or wide. (That’s a big door.) As you may have guessed, especially if you have some experience with any doors which are oversized, that keeping it straight is going to be a problem.

Any large door, over 7 ft tall or three-and-a-half ft wide, is going to present a problem with moving over time and the problems are exponentially worse if you’re dealing with a natural wood grain door. Due to the nature of natural wood, it expands and contracts in accordance with changes in the environment which results in the door warping, bending, twisting, or cupping.

Left to its own devices, such a large door will be problematic for the end user, requiring regular maintenance to deal with its propensity to move. That is, unless it has

Sing Core Inside

Patented Sing Core enables all the greatest door companies in the world to build enormous doors which will remain warp-free, even if they are constructed of natural wood species.

Of course, contemporary architecture and modern designers have resorted to using non-natural faux wood grain materials such as HPL to prevent the warping of architectural flush wood doors, but even so, those incredibly large doors still presented a problem with staying straight.

SingCore’s patented and patent-pending warp-free door solutions along with the years of technical expertise of his True Flat Team, can help create high precisions architectural doors results unsurpassed by any previously available door-building technologies.

These new leading-edge door manufacturing processes and anti-warp materials are able to produce doors of any size, made of any flat building material (yes, even natural woods) which can be covered by Sing’s unprecedented,

50-year Warp-free Guarantee

All SingCore’s premium flush wood doors are covered by a 50-year guarantee which covers any movement, as doors made with these technologies with not warp, bend, twist, cup, or otherwise fail (including structure and delamination) for 50 years.

No other company can offer such a guarantee on an Eco-friendly, lightweight, high-strength wooden flush door.

Added Architectural Benefits

Besides being warp-free and having the best and most long-lasting guarantee in the world, architectural doors that have sing Core inside also have many other extraordinary characteristics, such as

1. Lightweight

Architectural doors made with Sing Core inside are 1/3 the weight of other solid core doors manufactured with wood-based door cores. Creating doors so light in weight is extremely advantageous in reducing transportation and installation costs, as well as reducing the expense of heavy-duty architectural door hardware which is based on the weight of the door. A lighter weight door also translates to reduced maintenance costs related to regular door operation which if the door is heavier will increase stress and strain on both the structure and its hardware over time.

2. High Strength

No other Eco-friendly, lightweight door is stronger than an architectural door with Sing Core inside as these are the only doors which are stronger than steel pound for pound, independently architecturally rated by University at 660+PSI (many times stronger than commercial honeycombs used in aerospace at 10 to 110 PSI), making them the most sustainable doors known to man on planet Earth.

3. Fully Insulated

Even if your primary interest is having an architectural wood door that is straight and true, you might be pleasantly surprised that these are fully insulated for climate control (R 3.5 – R 6.5, or more, depending on architectural specs) and sport impressive sound deadening capabilities. It is not uncommon to find Sing Core inside the best soundproof doors in the most exclusive locations around the world in sound-controlled environments.

4. Solid

You should think about specifying Sing Core inside all your important architectural door projects.

Architectural Wood Flush Door Photos

- Custom Whiteboard Panels by Sing Core

What is a Dutch door?

What is a Dutch door?