The pride and joy of our SingCore brand is the fact that we are confident enough to offer an unmatched 50 year guarantee on all our professional level products.

The pride and joy of our SingCore brand is the fact that we are confident enough to offer an unmatched 50 year guarantee on all our professional level products.

Built to Last

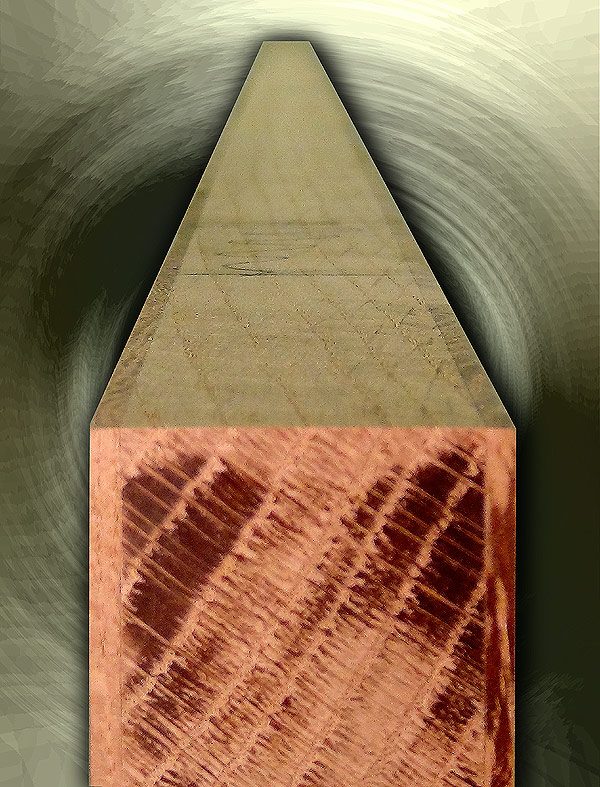

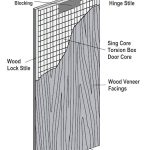

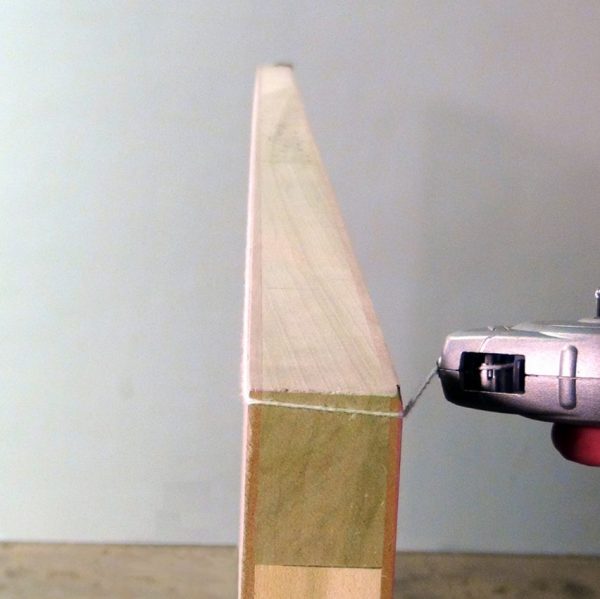

SingCore uses a space age proprietary core design, inspired by the high tech construction techniques pioneered by the aerospace industry. Our core material is an exceptionally high strength combination sustainable wood, high density high insulation foam, aluminum, and love. Because of our precision construction practices and intricate production machinery, we are confident that our doors will be here to last.

We are so confident, in fact, that we offer the only 50 year guarantee in the industry. This warrantee applies to all our “professional” level products, which is the default level of construction for our doors, and other architectural panel products.

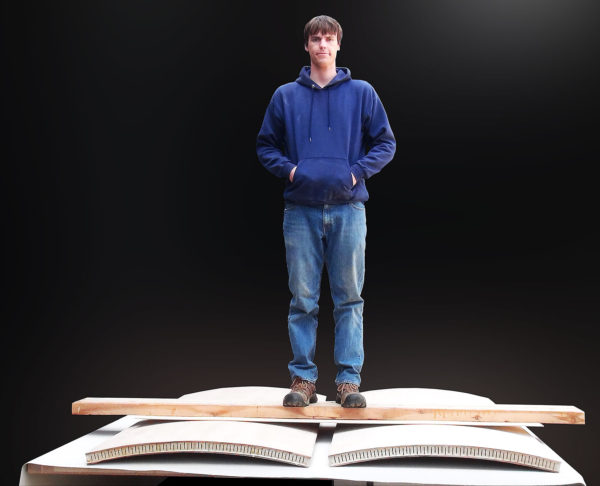

Unlike many of our competitors, we are confident in the perfect flat performance of doors over 4×8 feet. This includes exceptionally large doors, some exceeding 30′ in length. For SingCore, there is no door too big or too small. We are confident that no matter what we make, it will survive.

Exceptional in All Climates

From extreme cold, to extreme heat. Dry to damp. Or even extremely wind storm situations. Our SingCore panels will survive the test.

The unique qualities of our “honeycomb” construction methodology guarantee the structural stability of our panels in a wide variety of demanding applications. Our unfinished panels, where properly handled and installed, are set to last a lifetime:

- Extreme temperature differentials

- High wind load

- Damp or marine environments

- Very dry climates

- Freezing temperatures

With proper design in combination with your expert door installation and finishing skills, our panels are able to go where most other fear to tread.

A History of Excellence

SingCore is a company with decades of combined experience in high end oversize doors including: pivot doors, sliding doors, carriage doors, pocket doors, hinge doors, man doors, and more. Our skills have been put to the test in many extreme door situations including:

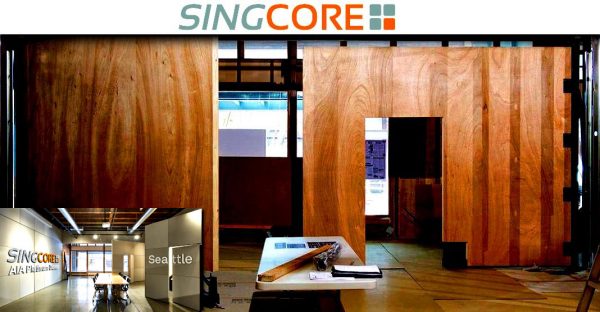

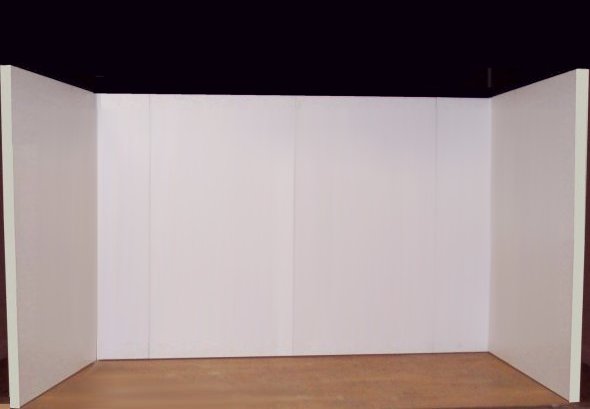

Seattle AIA Center for Architecture and Design

We are proud to have token part in the construction of extremely large pivot doors / moveable walls for the meeting space of the Seattle Center for Architecture and Design. These massive doors loom large in the center, and provide a functional centerpiece for the meeting space design. More info on our work with the Seattle CAD.

We are proud to have token part in the construction of extremely large pivot doors / moveable walls for the meeting space of the Seattle Center for Architecture and Design. These massive doors loom large in the center, and provide a functional centerpiece for the meeting space design. More info on our work with the Seattle CAD.

One World Trade Center, New York

A project built by some of the most renowned millworks in the country, our contribution to the construction of the One World Trade Center in New York was two pairs of 16′ tall pivot door panels for installation in the China Sky Center. These massive white oak pivot doors are trusted by our clients in New York to last in the high traffic commercial environment, as a center piece of the room design. Coming in at only 220 lbs each, these doors are amazingly light for their size. More info on our work with the One World Trade Center.

A project built by some of the most renowned millworks in the country, our contribution to the construction of the One World Trade Center in New York was two pairs of 16′ tall pivot door panels for installation in the China Sky Center. These massive white oak pivot doors are trusted by our clients in New York to last in the high traffic commercial environment, as a center piece of the room design. Coming in at only 220 lbs each, these doors are amazingly light for their size. More info on our work with the One World Trade Center.

Let SingCore Back You Up

We here at SingCore are ready to hear about your next project. No door is too big or too small for our crack team of door panel experts. Contact us with your project details today!

At SingCore, our panels’ exacting level of straightness is our product’s defining quality. SingCore doors, oversize doors, and architectural panels will not warp under any circumstances (see our best in the industry

At SingCore, our panels’ exacting level of straightness is our product’s defining quality. SingCore doors, oversize doors, and architectural panels will not warp under any circumstances (see our best in the industry