The strongest, lightest weight wood-based building material in the world is lightweight wood with Sing Core inside. Now, that’s a bold statement, but one that proves to be true time and time again across the board in all industries.

Inventor Peter Sing using combinations of his patented and patent pending lightweight wood manufacturing technologies can create lightweight wood structural building materials which are hybrid and composite materials which expand the realm among contemporary architectural projects in America and around the world.

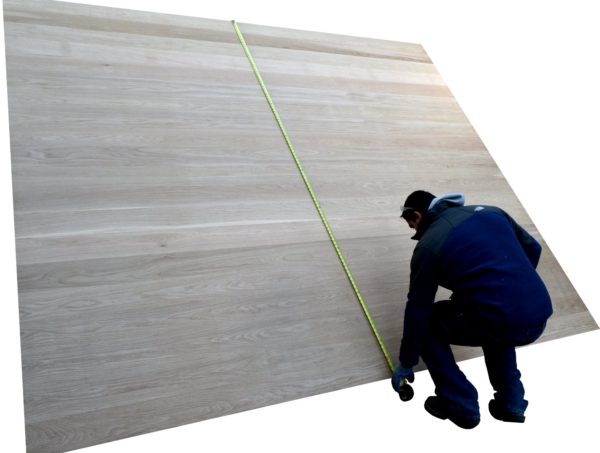

Available in any format, such as panel, post, and beam, Sing lightweight wood products are lighter than other wood-based building materials (one-third the weight or less, depending on the specifications) and stronger than steel (University independently tested at 660+ PSI) without compromising the highest precision (+/- .006 in.) tolerances.

This is why Sing’s lightweight wood is used to build large high-tech modern doors from military installations as well as featured installations in the most expensive homes of billionaires worldwide.

Sing’s special brand of large lightweight wood doors are impacting the doors industry in a huge way especially in the area of the oversized door market. Big doors make a massive impact on people as they encounter such large doors, such as an enormous pivot front door, which seems to leave the most lasting impression.

While contemporary architecture is more commonly moving toward bold designs, the limitations of available building material can be problematic when designers, engineers, and contractors are tasked with bringing such visionary projects to life.

For instance, as every major door manufacturer in the world knows, if a wood door is over 7 feet tall and three-and-a-half feet wide, you are looking for trouble, because not long after installation (while the grand opening may unfurl flawlessly) those bid doors are going to warp.

That’s where Sing’s core comes into play to literally save the day.

Solution to the Large Warped Door Problem

The biggest and best door companies in the world rely on Sing’s lightweight wood doors to deal with the complications presented in all large doors of any size or style, whether it’s a tall, skinny door at NASA, or a huge 40 ft. tall sliding door in a military installation, Sing’s patented lightweight wood technologies can create the largest doors which can be

GUARANTEED for 50 YEARS

Not to warp, bend, twist, or otherwise fail.

If it’s the first time you’ve heard of it, it sounds too incredible to be true, but large lightweight wood doors with Sing’s core inside are actually guaranteed to remain warp-free for 50 years. Until now, such a guarantee was unheard of in the door industry.

The Secret of Building Warp-free Lightweight Wood Doors

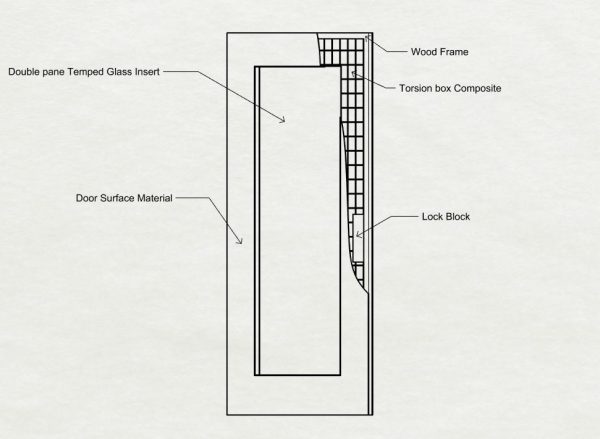

The secret of building warp-free lightweight wood doors is found inside Sing’s patented reinforced torsion box core material, which is similar (and inspired by) the various honeycomb cores used in the aerospace industry where he became aware of the limitations of traditional honeycomb core materials.

His unique composite hybrid warp-free solution is the key to making what has been referred to by the most high-profile door manufacturers in the world as the key ingredient in the world’s best doors.

How to Build Sing Core

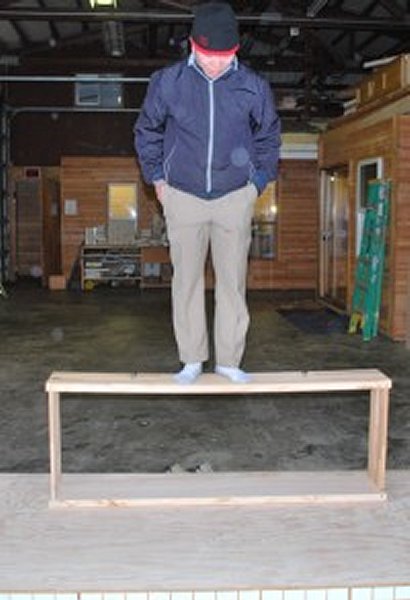

First off, you start with a torsion box grid structure, only instead of orienting the grain of the wood torsion box horizontally, as you normally would, you turn it, so the grain is vertical instead. Vertical grain torsion box grids are many times stronger than horizonal grain. This single improvement was the beginning of the answer to building a better honeycomb substructure material.

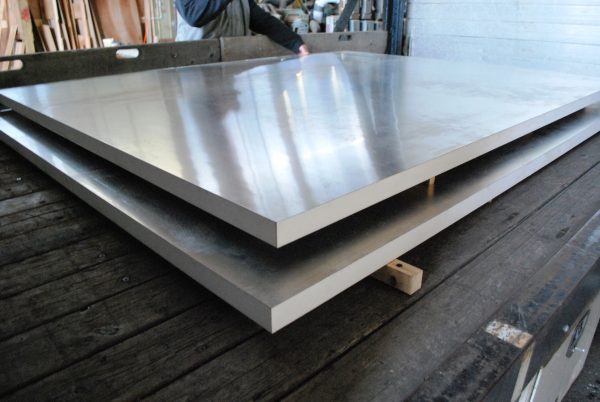

But Sing didn’t stop there because the inside of each box was empty, so he decided to add rigid foam to fill the empty voids. Sandwich this hybrid torsion box core between to flat sheet goods, and there you have it: Sing Core. And Mr. Sing has complete control of the size of the reinforced torsion box grid, so to increase the strength, he can make the grid size smaller, as little as 2-inch by 2-inch squares for super strength Sing Core, the lightest and strongest substrate in the world.

But, that’s not all.

Wood Species and Warp Tendencies

Every wood species has its own unique tendencies to warp, so Sing devised an entirely new system of enhancing his Sing Core substrate with strategically placed anti-warp materials which counteracts the natural inclination of each wood species to move.

In this way, each custom door that Sing’s company helps to design and build to deliver warp-free high-performance over a 50-year service life (even though, as inventor/president says, “Each door is built to last centuries, but I guarantee it for 50 years.”) is an individual work of art.

Not Limited to Large Lightweight Wood Doors

The very same patented sing technologies that goes into each of their lightweight wood doors can be applied to doors made of nearly any available flat building material. A few examples would include

| Aluminum Doors | Brass Doors |

| Cement Doors | Concrete Doors |

| Cold Rolled Steel Doors | Diamond Plate Steel Doors |

| Fiberglass Doors | FRP Doors |

| Galvanized Steel Doors | Hot Rolled Steel Doors |

| HPL Doors | Kevlar Doors |

| Lead Doors | Lexan Doors |

| Magnetic Doors | Masonite Doors |

| Metal Doors | Rare Species Wood Doors |

| Stainless Steel Doors | Steel Doors |

Any of the doors listed above could be made lightweight and stronger than steel pound for pound with Sing Core inside.

Not Limited to Doors

While the veracity of this invention has been proven and withstood the test of time in the large oversized door marketplace, Sing’s lightweight high strength core technology translates to any project where size, weight, and strength might present problems in any design.

You might be surprised to find that entire homes have been built entirely of Sing Core products.

| Aerospace Panels | Broadcast Stations |

| Clean Rooms | Cold Storage Rooms |

| Equipment Enclosures | Furniture |

| Hurricane Panels* | Impact Resistant Walls |

| Insulated Flooring Systems | Kitchen Islands |

| Large Conference Room Tables | Marine Bulkheads |

| Mezzanine Floors | Museum Displays |

| Recording Studios | Signboards |

| Solar Panels | Sound Isolation Booths |

| Submarine Panels | Temporary Portable Garages |

| Theater Walls | Trade Show Booths |

| X-ray Systems |

In other words, the possible applications for Sing Core are almost limitless. So if you’re having issues and challenges associated with weight and dimensional stability, there’s a good chance that Sing Core may be the answer you’re looking for.

Contact Sing Core for more information.

Large Lightweight Wood Doors

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.