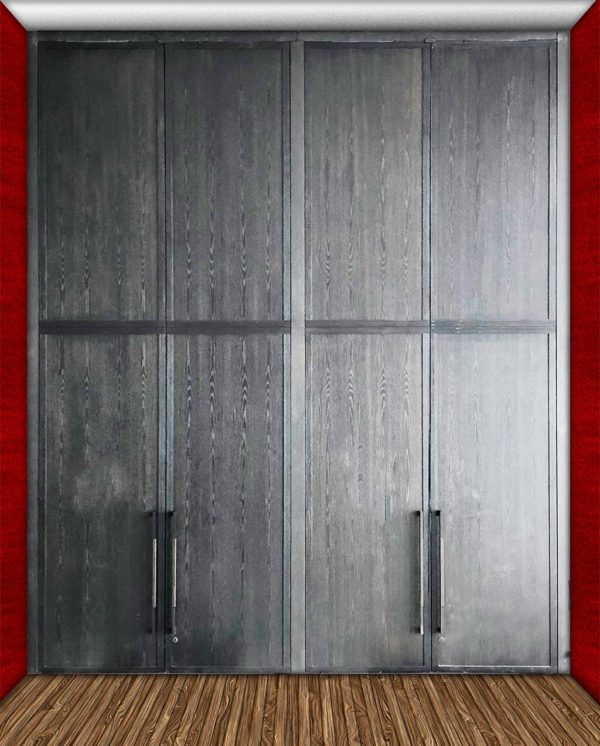

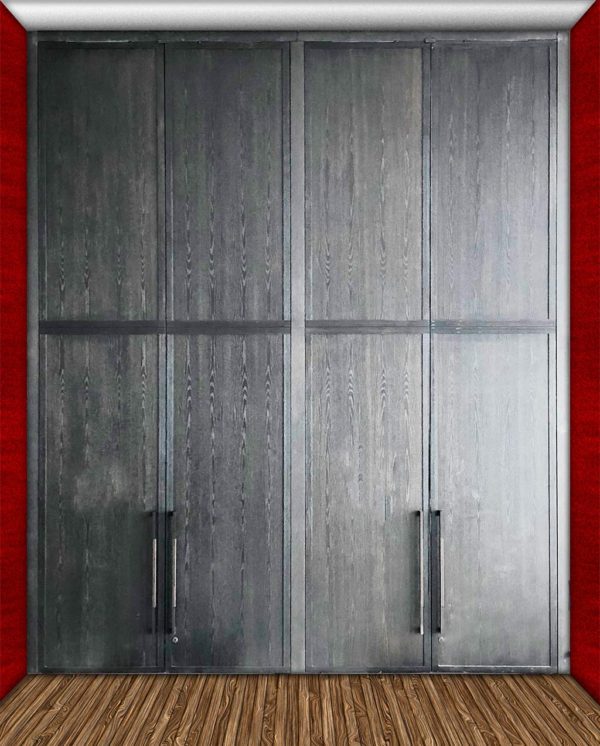

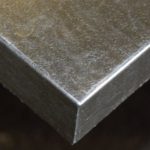

94 1/2″ x 31 3/4″ pivot door at Martha’s Vineyard Passamaquoddy by Tate Builders

As part of SingCore’s long march to excellence, we sustain our resolve with the knowledge of the role that our humble panels can play, when combined with the intrepid skills of our millwork partners and comrade contractors from the East coast to the West and back again. Here, we would like to take a moment to congratulate our friends at Tate Builders Inc on their successful finishing and installation of SingCore door panels at Martha’s Vineyard Passamaquoddy.

The magnitude victory of our in this combined struggle is evident at first glance, even to the untrained eye. But in this regard, we must defer to the skill and commitment of the builders.

Our contribution is not clearly visible to the eye, but immediately evident to everyone who has the luxury to work with our product. We manifest three virtues, which are part of our seemingly endless “structural revolution”:

- The perfectly straight and narrow

- Unbreakably strong

- Will not give up for 50 years or more.

Case Study

Technical details about elements of this installation.

- Finishing and Installation: Tate Builders Inc

- Location: Martha’s Vineyard Passamaquoddy

- Type: Pivot Door

- Hardware: concealed FritzJurgens pivot hardware

- Dimensions: 94 1/2″ x 31 3/4″

- Structural Skin: 1/4″ Luan Ply

- Finish Skin: Textural wallpaper

- Weight: ~50 lbs

More that Just a Door – An Ideal

At SingCore, we are not in the door business, we are in the People business. Our profound vision is to architects, liberate millworks, construction companies, and all workers of the world from the shakes of large door manufacturing. For use, every door is unique and built directly to suit the purpose at hand.

Our process permits no waste, and very little slow moving. Working with a central goal in mind, every one of our factory workers pours their blood, sweat, and tears in to the realization of our monolithic vision. A new and glorious beginning, and a superior door.

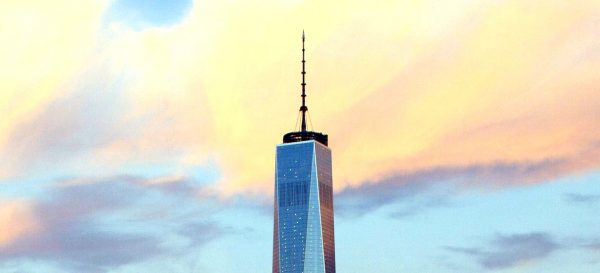

This ideal originated in the mind of one man, who germinated it in the bustling cities of the East, but grew to maturity in the seclusion of the West. Now, it has succeeded in assaulting the very bastions of American capitalism, including Seattle, Los Angeles, and New York.

Yet the vision ever grows stronger through constant turmoil and continual rebirth. This is not the dominion of any one man, but rather the manifest will of humanity, as realized by our benevolent founder, inventor, and SingCore president Peter Sing.

Up Next – The World

SingCore is constantly expanding its vision and authority. There is no one in the door space that can match our prowess and capability. Yet, we are not content to rest on our laurels.

Sing’s star is rising in the east to ever grander apexes of large, custom doors, architectural panels, high end furniture panels, home construction, SIPs, alternative housing. The future is ripe for the taking. We hope there will soon be no room to hide from our reach, which will extend across the planet to touch the lives of every day individuals.

SingCore is ready to spring to action in defense of your next project. With custom, built to spec panels, all we need is length, width, and thickness to manifest your utopian fenistary vision.

Contact us today!