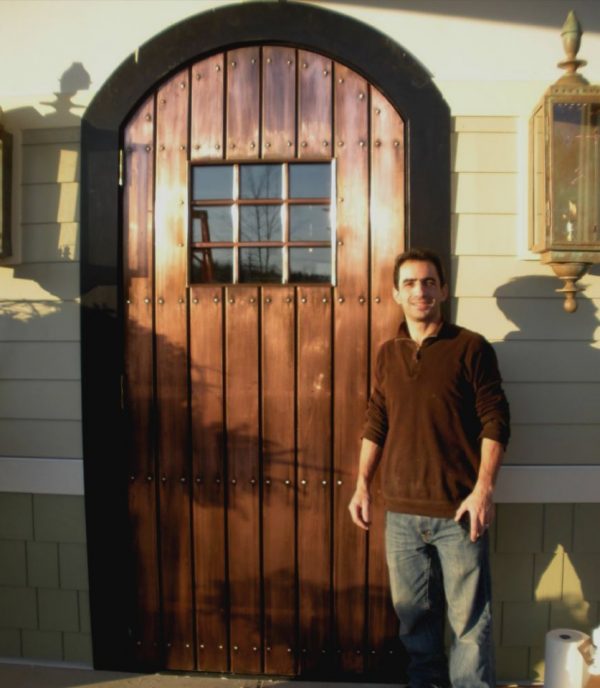

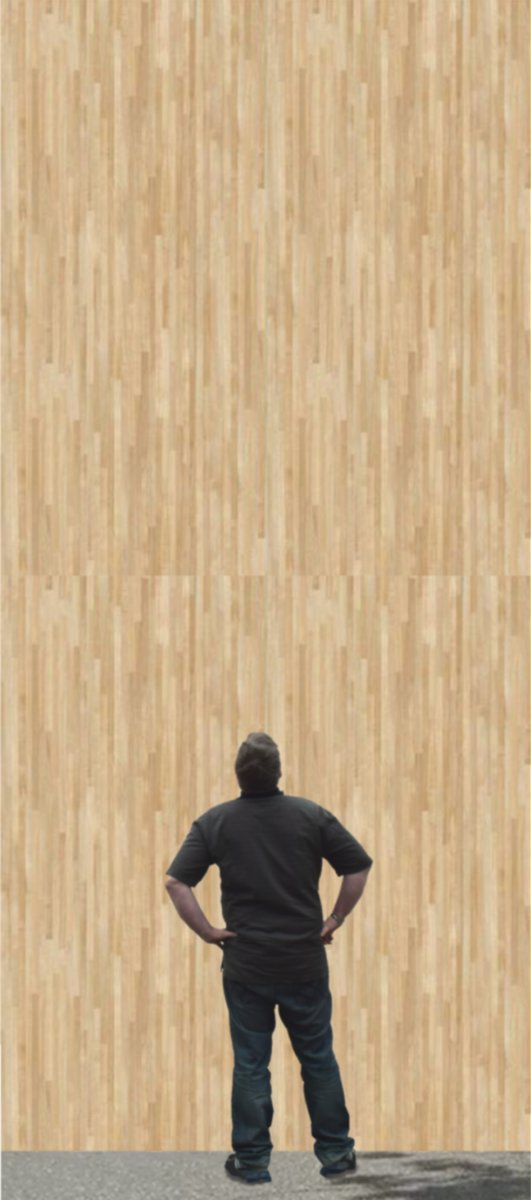

When it comes to big doors, no one does it better than Sing Core. Who else can make an Eco-friendly oversized front door that is made in the USA, fully insulated, lightweight, stronger than steel pound for pound, and guaranteed not to warp or fail for 50 years? Nobody, unless the door in question has “Sing Core inside.”

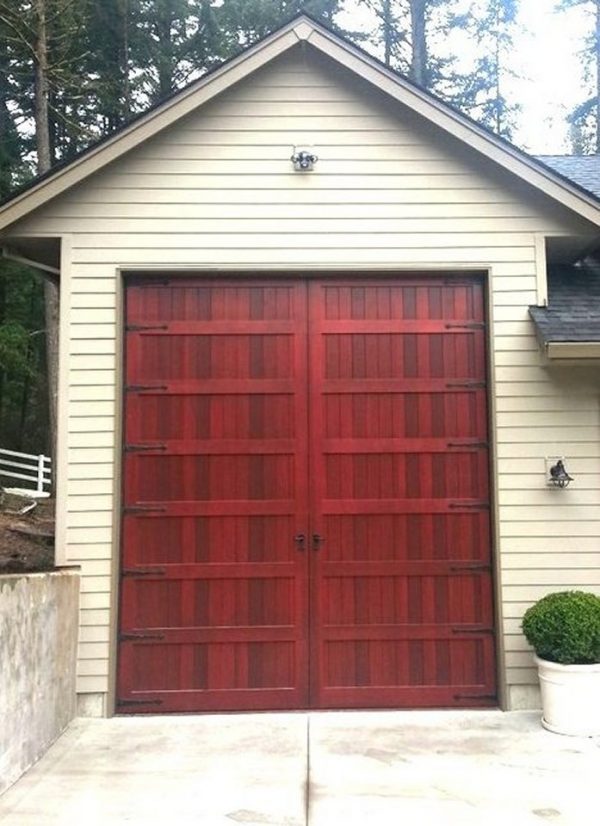

Front doors are not only the first thing that you see when approaching a structure, but they have a unique challenge as one side of the front door faces the interior and the other faces the exterior. This is the perfect storm for the warping of exterior doors.

A warped entry door is a problem because it is a huge security issue if the front door cannot be secured because the locking mechanism does not line up correctly. This can also be a problem for climate control for certain times of the year when weather can be extreme in some geographic locations.

Sing Core oversized front doors could be made of any available flat building material but the most problematic entry doors are wooden front doors. Wooden front doors cause the most challenge for warp due to the nature of the natural wood grain to move as it adjusts to changes in the surrounding environment.

Sing Core’s ability to provide a warp-free solution for this type of elegant oversized front door includes the use of patented and patent-pending technologies which are keenly created and suited for the particular door, taking into consideration the height of the door, the width and thickness. Other factors include the wood species used and how much of the wood is featured on the exterior wood doors, as well as taking into consideration the overall seasonal climate where the door is installed, which direction the door is facing, and whether the door is 100% exposed, or not.

All these things factor into the unique creation of a warp-free oversized front door substrate which considers all the aspects of the door. This is a process which is unique only to Sing Core and it’s what makes each door with a 50-year warp-free guarantee an individual work of art.

Many of the best and largest door manufacturers call on Sing Core to assist them in building an oversize front door of integrity and long-lasting performance. Prior to working with Sing Core, many of the largest companies would just refuse to make the big front doors because they knew these big entry doors were going to be problematic.

Custom door manufacturers and the most proficient millwork companies and craftsmen might build out the door to your specifications, but no one would be willing to put their name on the bill more than once, guaranteeing any degree of well-maintained straightness, as prior top Sing Core, this was just not possible. You might be compelled to sign your name the first time due to your level of confidence in your abilities, but after the first time, you’d use the waiver.

Contractors routinely excluded the big front entry doors from their warranty rider(s) for the same reason. It’s like, “if you want a big door, then fine. We’ll find someone to build it for you, but good luck trying to keep it straight.” If you want a big door, you can have it, but the regular maintenance for large wooden front doors is on you, and you can count on it.

Making a large Eco-friendly, lightweight, high strength door that is fully insulated and stronger than steel pound for pound, just cannot be done without Sing Core.

Do you want more from your door?

How about

•  Eco-friendly

Eco-friendly

• Any size

• Any material

• Lightweight

• High strength

• Fully insulated

• Use indoor or outdoor

• 50-year Warp-free guarantee

• Structure guarantee

• Made in the USA

The sky is the limit (and beyond, if you are our client, like NASA) as we build your architectural oversize front door to your specifications. Any size, any light cut out, any material, such as aluminum, blackboard, brick, cement, cold-rolled steel, concrete, diamond plate steel, fiberglass, FRP, galvanized steel, glass, HPL, Kevlar, LVL, magnetic board, MDO, stainless steel, whiteboard, even the most difficult material to keep perfectly straight over long spans:

Natural wooden front doors

Sing Core can provide the biggest and best millworks and custom door manufacturers with a superior warp-free oversized front door made of any available natural wood species, such as alder, ash, birch, cedar, cherry, cypress, dogwood, Douglas fir, elm, eucalyptus, fir, hemlock, hickory, mahogany, maple, oak, okoume, pine, poplar, spruce, or walnut, just to name a few.

All perfectly flat and guaranteed warp-free for 50 years.

- lightweight honeycomb door