Pocket doors have become an integral part of modern architectural design. Despite the many advantages of pocket doors, they do present unique challenges in both the manufacturing and the installation process.

About Pocket Doors

Pocket doors are desirable as they are invisible in the opened position as the pocket sliding doors are hidden away in cavities within the walls in one, or two opposing, wall(s). Pocket doors serve as a retractable room divider, functioning as an elegant and effective method to separate one large space or two adjoining spaces, while the sliding door divider(s) disappear(s) into the wall.

Proceed with caution, as pocket doors can be hugely problematic if they move according to changes in the surrounding environment. A warped pocket door will damage the finish as it rubs against neighboring surfaces and if it bends or cups too much can get lodged inside the wall, and the bigger the pocket door, the greater likelihood of warping.

There are many reasons to have your pocket doors made with Sing Core but the number 1 reason is to stop worrying about warped pocket doors once and for all by specifying

Sing Core Inside Your Pocket Door

Thanks to inventor Peter Sing’s patented and patent-pending large pocket door technologies, you can have an Eco-friendly pocket door that is lightweight, high strength, fully insulated for sound deadening and climate control, covered by Sing’s

50 Year Warp-free and Structure Guarantee

There is no other way to build a high precision (Sing Core tolerance is +/- .006 in.) sustainable pocket door that can remain straight and true, spanning the test of time.

The Best Pocket Doors

Sing Core has become known for making some of the largest, most impressive sliding doors on the market. Pocket doors are sliding doors that slide into a pocket in the wall. Certain customers have come to know Sing Core, not only for our sliding doors, but also for our magnificent pocket doors. Introducing the best pocket doors!

Pocket Door Challenges

The concept of pocket doors seems simple very simple. They are similar to sliding doors in that they slide on tracks and typically use rollers to open and close. The big difference is that they slide into a pocket that has fixed dimensions inside the wall. If the door warps or skews, the door cease to function. You will not be able to open or close the door because warping will change the dimensions of the door.

Warp Free Pocket Door

Over decades, we have developed our patented and patent pending materials that allow for super strong, light weight, warp free door construction. Warping and skewing present significant problems for pocket doors, because pocket doors must slide into a fixed space inside the wall. Any deviation from specifications will prevent the door from fitting into the space. When this happens, your door will cease to function. You will need to buy a new door, change out your hardware that may bend or break as a result of door malfunction. In some cases, you also need to rebuild your door frame or your walls when they are ruined from doors being opened and closed.

But we have solved all of the problems associated with large pocket doors and large sliding doors. When you use Sing Core products, you not only get a door that exceeds AWI standards in terms of warpage, you also get a door that’s guaranteed against warping for 50 years. Because of our special design methods, you will get a door that ensures proper functionality for decades.

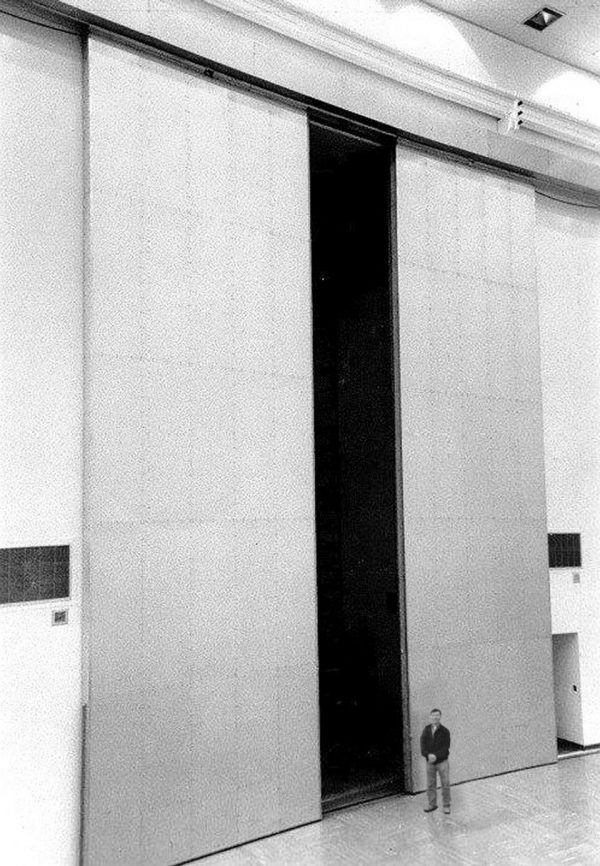

Large Pocket Doors

The larger the door the bigger the challenge. Large pocket doors are more susceptible to warping. In order to function properly, they must be specially designed to resist warping. Larger doors must be specially constructed so that they are warp free on installation, as well as, over time.

Ultra High Strength – A large pocket door must be exceptionally strong to stand up to the most rigorous use. At Sing Core, we have revolutionized door strength with Peter Sing’s patented and patent pending technology that allows us to build doors that are very high strength, tested independently at over 660 PSI.

Super Light Weight – Up to 90% lighter than solid wood doors. Sing Core’s specially engineered core uses Peter Sing’s revolutionary design to bring a solid door strength to doors that allows for super light weight performance.

Straight/Warp Free – Specially designed stiffeners built into our doors make sure your doors are warp free over the long haul for better performance and function.

Structurally Stable – With our groundbreaking process, we can make doors that are built exactly to your specifications, and will not skew or shift over time. That way, you have a door that functions worry free for decades.

Eco-friendly – We support sustainability by using renewable, eco-friendly materials, so our products are better on the environment.

Guaranteed – When it comes to guarantees, no company on the market can do better. Our Sing Core Professional Panels are used for doors and other high end applications where stability and precision are of the utmost importance. All of our Sing Core Professional panels come with a whopping 50 Year Guarantee against warping, cracking, breaking, and skewing. Name one other company who can do this. Most companies don’t even offer a one year guarantee, but we can do this because our products have such a strong track record of performance.

No one can make panels as large, yet warp free like we can! You have our guarantee on that.

All of our products are 100% made in the USA. We take pride in supporting our country. That’s why you won’t find any products that aren’t made in America here. We also use high quality inputs that are sourced from local suppliers.

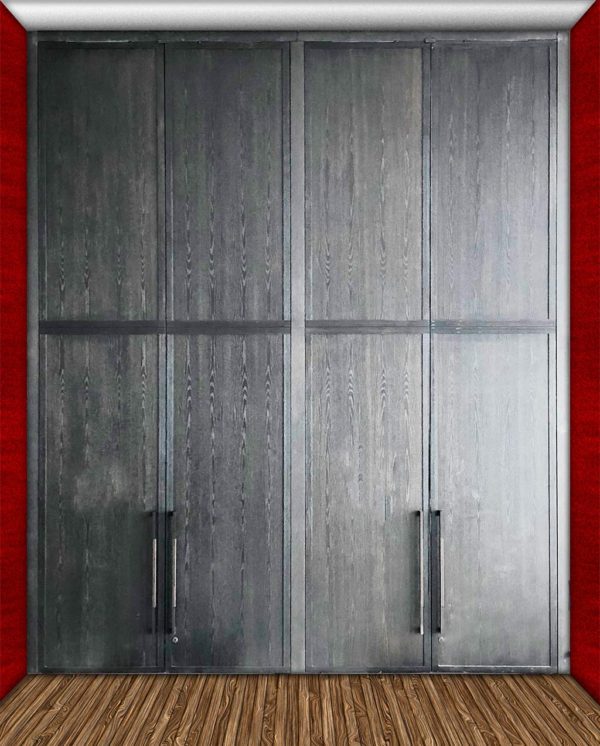

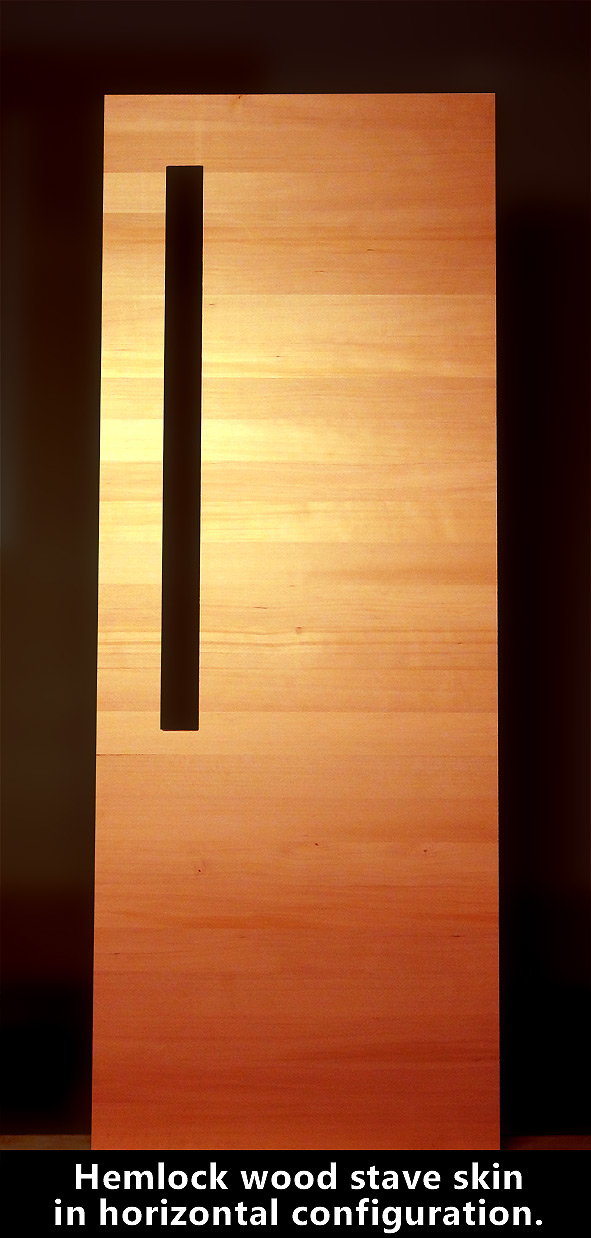

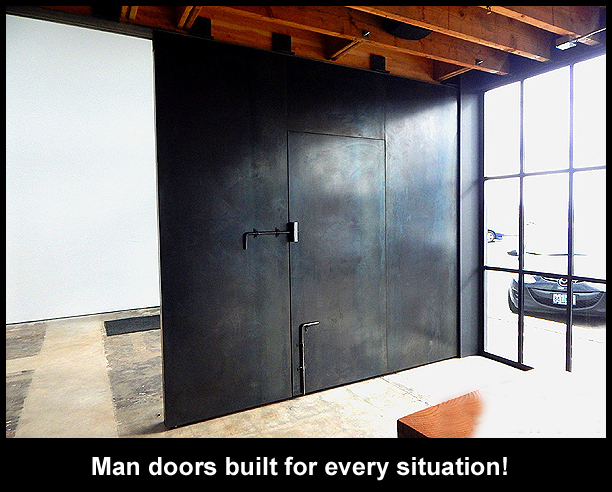

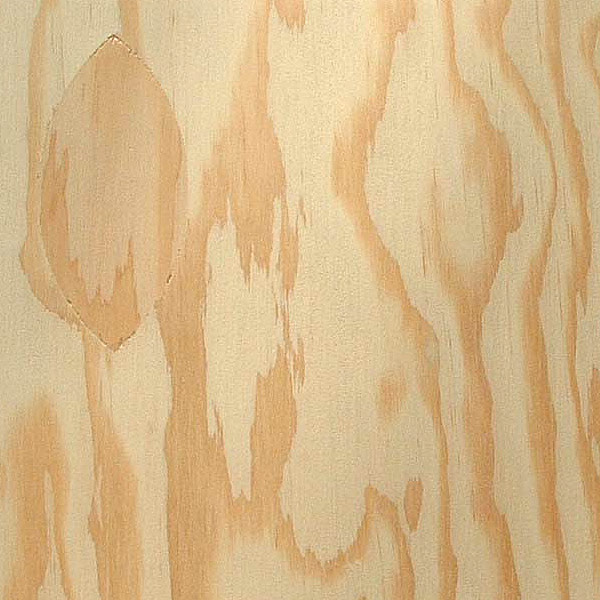

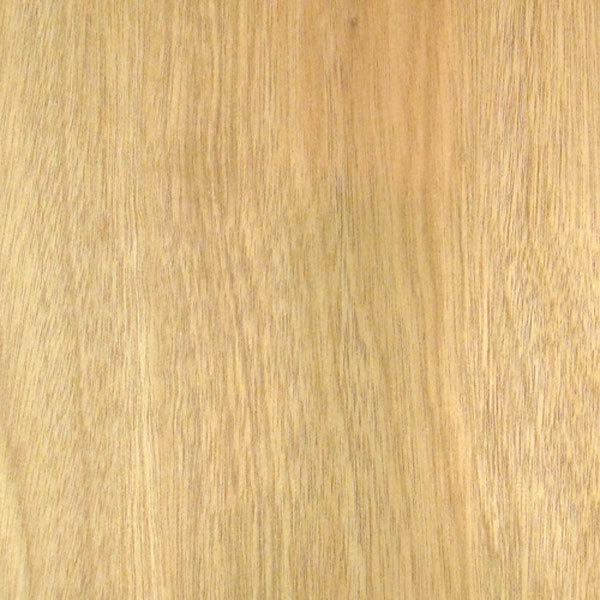

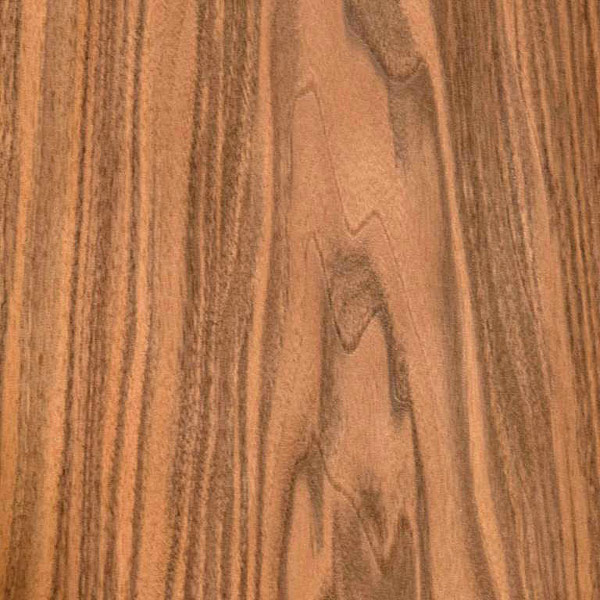

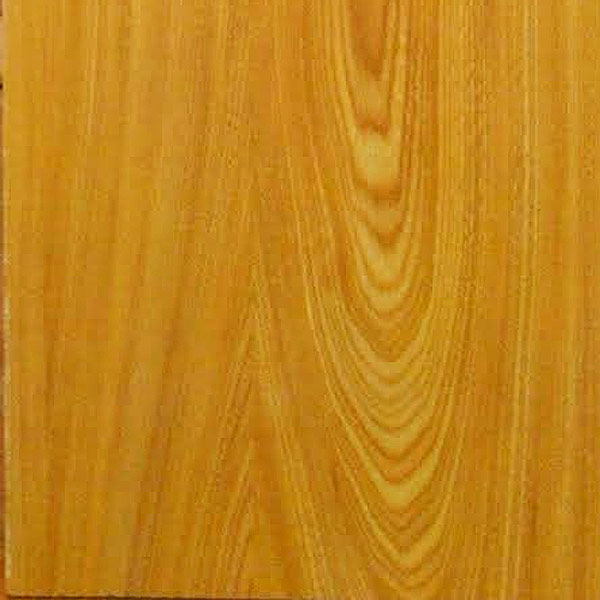

Door Skins

Our door system allows you to specify almost any skin for your doors. We specialize in high quality wood and metal doors. We have several options depending on your budget. Our paint grade ply option is our most economical option. Next is our hardwood veneer option. Mahogany, oak, walnut, and alder are popular. We also use 1/8″ wood stave on our highest end option, which gives you a solid wood appearance, but has our specially engineered core to maintain the light weight feature our doors are famous for. We also make metal doors. In our metal doors category, we specialize in cold rolled steel, but we also have a very popular aluminum option.