When you’re not just looking for any sliding glass doors, there’s a good chance you’re looking high and low for the best sliding glass door to suit your needs, your particular taste(s) as well as beautiful sliding French and patio doors. Normal, off the shelf glass sliding doors are not going to suit what you want in a sliding glass door. Chances are you’re looking for the best sliding glass doors, doors that are not your run of the mill sliding French or patio doors, but unique one of a kind sliding glass patio doors.

About Sliding Glass Doors

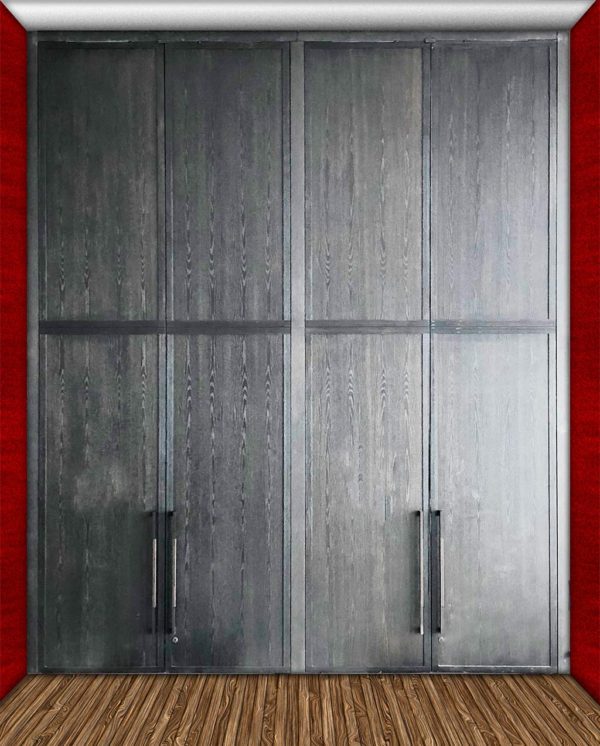

Standard sliding glass doors come in vinyl, fiberglass, rolled or extruded aluminum, and in the more expensive projects featuring natural wood to show case and frame the metal. Enter the new generation of large sliding glass doors specified and insisted upon by the most high-end door companies, architects, designers, engineers, and custom sliding glass manufacturers in the world.

The most popular sliding glass doors are inexpensive, made of vinyl, fiberglass, rolled or extruded aluminum. You are not likely to find these materials in the higher caliber jobs in the most elegant locations around the world. In these most exclusive projects, you’re more likely to find natural wood grains or hot rolled steel featured.

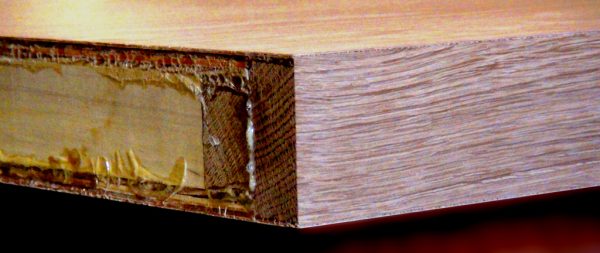

Now, you can have nearly any material featured in your sliding glass doors, with Sing Core inside to make the best sliding glass doors in the world. This new way of building impeccable sliding glass doors is thanks to Peter Sing’s patented and patent-pending sliding glass door frame material which enables the creation of Eco-friendly high-end sliding glass doors of any size to be built and be fully sustainable.

All backed by Sing’s unparalleled

50-Year Warp-free and Structure Guarantee

There exists no other way to build a lightweight impervious sliding glass door to come with such a guarantee without Sing Core inside.

If you really want the best sliding doors, you will need to enlist the skills and artistry of a local millwork or custom sliding door manufacturer.

Sliding Glass Doors

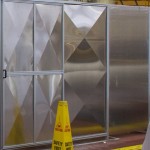

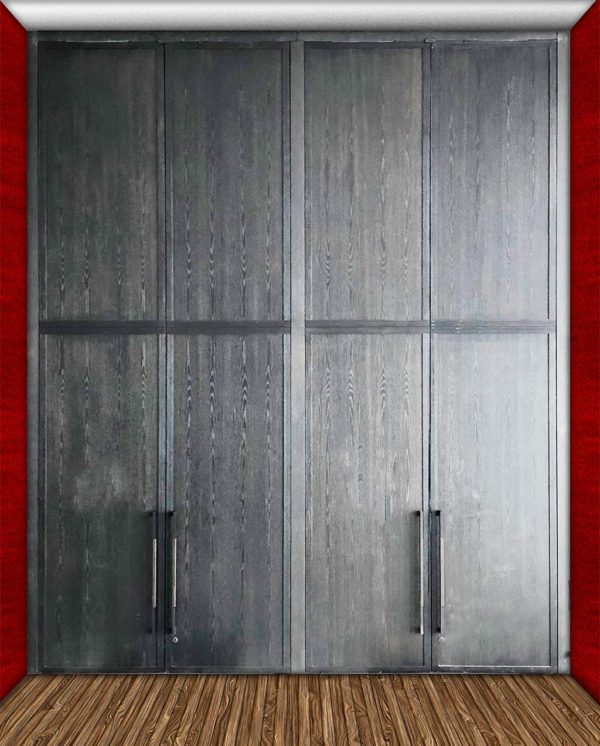

Sliding glass doors are the most prevalent and sought after styles of patio doors, which can and often do include several sliding glass doors in succession including overlapping sliding glass doors which are also called bypass sliding doors because one door slides over another door panel, which may or may not be a sliding patio door. Depending on the design, one or more glass doors may be stationary.

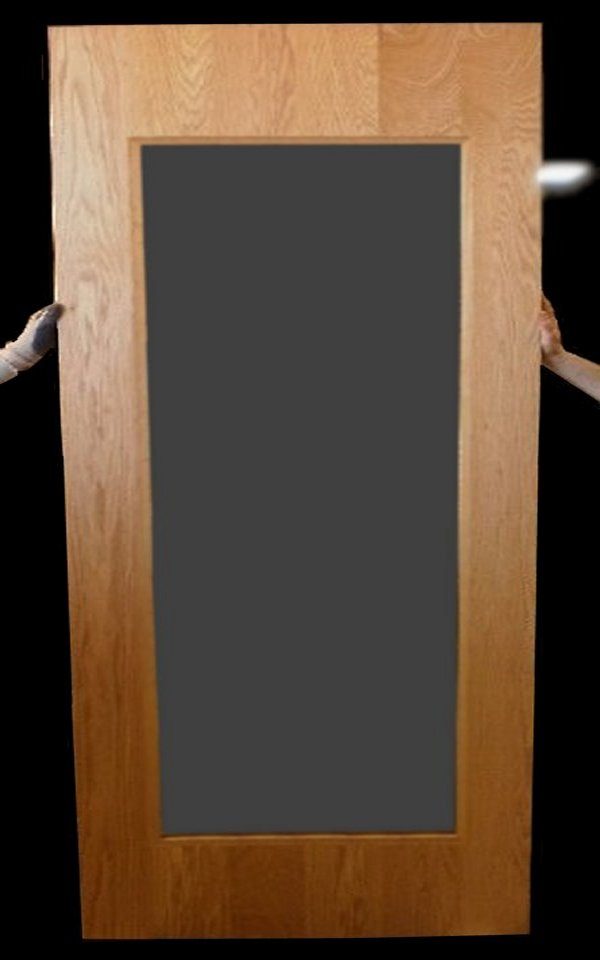

The best sliding glass doors featured in high end homes are made with wooden sliding doors that feature large glass window lite cutouts. It stands to reason, if you’re going to have a nice patio, you’re going to want to enjoy it both from the inside and the outside of your home. So, unless you’re primary concern is high security level patio doors which can be made of Kevlar and featuring Lexan clear polycarbonate, you’re going to want sliding patio doors with a view (glass installed).

Sliding Glass French Patio Doors

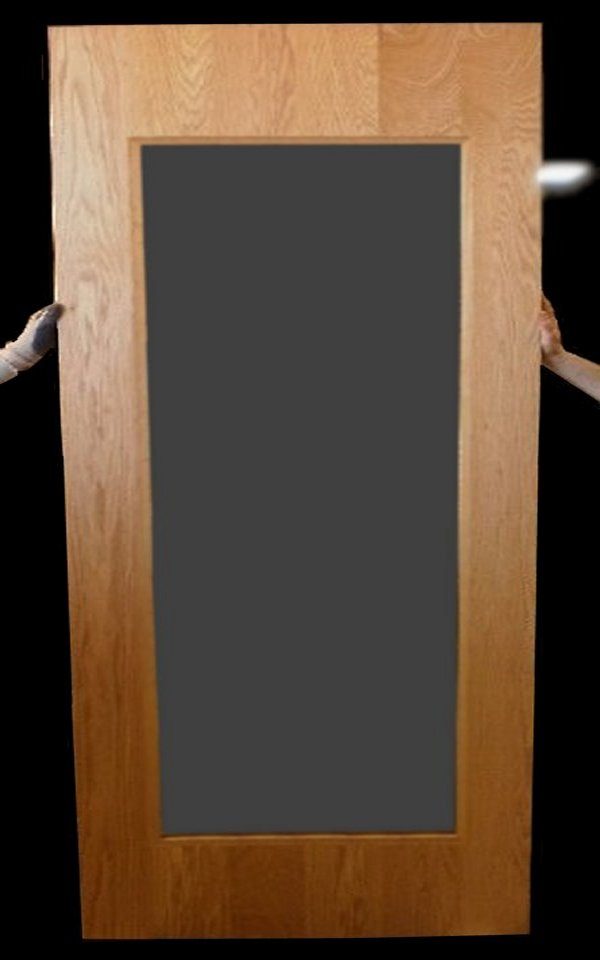

Those sliding patio doors with the big glass cutouts? We call these sliding glass doors, “French patio doors.” By definition a French door is a usually a wood door featuring a large window glass pane. Sliding glass French doors allow you to enjoy the beauty of the outdoors regardless of the time of year. French doors are Eco-friendly in that they maximize the availability of the natural lighting.

For The top of the line, highest end sliding glass doors, look no further. We can make panels that will shock and awe even the competition.

If your French patio doors have Sing Core inside, they are lighter in weight and also insulated for climate control and also sound deadening qualities, maximizing your investment for the most Eco-friendly French patio doors.

While the sliding French patio door is intended to provide access to and from the patio area, they are also elementally and visually impressive enhancing the overall appearance of any patio access area. Sliding French patio doors are by far the most elegant patio doors, and backed with Sing Core’s 50 year warp-free and structure guarantee, are by far the most sustainable patio doors.

Wooden Sliding Glass Doors

Since wooden sliding glass doors are the preferential choice of designers, architects and owners of the most expensive homes ($20 Million & up) chances are these are going to be wooden sliding doors which are featuring large lite cut outs and are likely to be very tall, which could be 16 ft. tall wooden sliding glass doors, or taller sliding glass French patio doors. Wooden sliding doors (especially if they are large wooden sliding doors) present a number of challenges for the architects, designers and millworks or custom door manufacturers who build them. The number one problem with any long span of wood is that it will warp. It’s not a matter of if the large wooden sliding door will warp, but when it will warp.

Since wooden sliding glass doors are the preferential choice of designers, architects and owners of the most expensive homes ($20 Million & up) chances are these are going to be wooden sliding doors which are featuring large lite cut outs and are likely to be very tall, which could be 16 ft. tall wooden sliding glass doors, or taller sliding glass French patio doors. Wooden sliding doors (especially if they are large wooden sliding doors) present a number of challenges for the architects, designers and millworks or custom door manufacturers who build them. The number one problem with any long span of wood is that it will warp. It’s not a matter of if the large wooden sliding door will warp, but when it will warp.

That’s why it’s so important to have Sing Core inside your large wooden sliding doors, because a warped wooden sliding door which does not open of close is not a door at all. Although, if your door has a large window glass pane lite cutout, you will still have the view, even if the door fails, your wood French patio door can be a French patio window.

The wisest most efficient designers and architects increasingly are specifying that all their large wooden sliding doors with glass and wooden French patio doors have “Sing Core inside.”

Sliding Glass Door Design

The design of glass sliding doors, and sliding French doors in particular, can be complex and may require a true team approach to the glass sliding door design. The architect can specify the glass sliding doors, and the designer (who may also be the architect or the owner) knows what they want. The concerted efforts of the custom glass patio door builder or manufacturer, the millworks, (as well as Sing Core, if specified) and the install team, must work in tandem to solve all the pending challenges that may arise from the glass sliding door design.

The design of glass sliding doors, and sliding French doors in particular, can be complex and may require a true team approach to the glass sliding door design. The architect can specify the glass sliding doors, and the designer (who may also be the architect or the owner) knows what they want. The concerted efforts of the custom glass patio door builder or manufacturer, the millworks, (as well as Sing Core, if specified) and the install team, must work in tandem to solve all the pending challenges that may arise from the glass sliding door design.

Extra care must be taken in the selection of the glass sliding patio door hardware, ensuring that it is rated for exterior use, and also matched to the weight of the sliding patio glass door as it was designed. The weight of the sliding glass patio doors dictates the types and styles of sliding patio door hardware which will be necessary for improving performance and reducing maintenance over time.

For patio doors that have solid warp-free Sing Core composite core inside, these patio doors will be lighter in weight than other solid core doors, reducing the cost of what otherwise might require heavy duty sliding door hardware, which can cost many times the cost of the sliding doors themselves.

Modern Patio Doors

In this day and age, modern glass sliding doors need not adhere to the same design characteristics as their sliding patio door forerunners. In the most contemporary architectural designs custom lite openings can be designed which contrast wildly in comparison to earlier traditional designs.

It is common for Sing Core to pre-cut custom lite openings in modern sliding patio doors based on the visionary drawings of the contemporary architect, designer or owner.

By altering and creatively designing the glass openings in an otherwise sliding French door configuration, a unique glass design and install can increase the effective curb appeal and radically enhance the perceived value of a home, when the owner desires to be uniquely separated from the pack.

Plus, high end modern sliding patio doors need not be limited to being manufactured of wood. You might see these highly individualized, one-of-a-kind patio doors made of hot rolled steel, copper, or concrete, because custom patio doors with Sing Core inside could be made of any available flat building material.

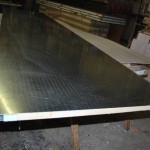

Especially if you’re considering utilizing hot rolled steel for your large doors, Sing Core can help to mitigate the damages caused by the heavy weight of hot rolled steel doors with interior steel frames that require welding. This allows you to build hot rolled steel doors of immense size that are high precision, just like other types of Sing metal.

Especially if you’re considering utilizing hot rolled steel for your large doors, Sing Core can help to mitigate the damages caused by the heavy weight of hot rolled steel doors with interior steel frames that require welding. This allows you to build hot rolled steel doors of immense size that are high precision, just like other types of Sing metal. When you buy our professional panels, you get our Signature 50 Year Warp Free Guarantee. It ensures you decades of worry free performance. Sing Core Panels are 100% made in America. Every panel is handmade, so you get the best quality possible.

When you buy our professional panels, you get our Signature 50 Year Warp Free Guarantee. It ensures you decades of worry free performance. Sing Core Panels are 100% made in America. Every panel is handmade, so you get the best quality possible.