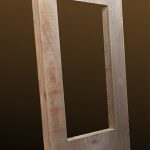

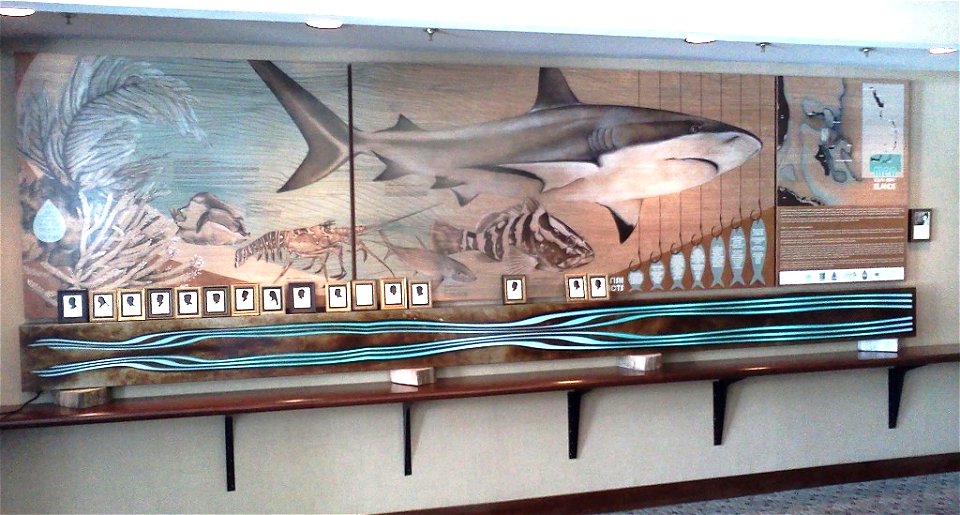

One of the best uses in emerging technologies attributed to the Sing Core solution for sliding doors is that of sliding French doors. In the scope of sliding French doors, the door is framed with a significant amount of solid material detail, such as is found in wooden sliding doors or aluminium sliding doors, but the main visual feature of the doors is a large pane of glass, similar to that of a glass sliding door. The result is a French sliding door which features the best of both worlds, an elegant frame with a large glass opening (lite opening).

Large Sliding French Doors in Office Building

Sliding French doors are more common in exterior uses, such as sliding patio doors.

Sliding Patio Doors

Sliding French doors make fabulous sliding patio doors which can feature many patio sliding doors in a line to offer greater visibility between the indoors and outdoors. Plate glass sliding door can be extremely heavy and may risk injury of little fingers which may be in the wrong place at the wrong time. The lighter weight Sing sliding door solution helps mitigate the risk of injury from sliding patio doors, while offering increased safety and security as wells as a degree of insulation which would not be possible for a simple sliding glass door left to itself.

Sliding Internal Doors

While sliding doors are used to separate the indoors from the outdoors, increasingly they are finding their way inside the home in a variety of sliding internal door applications. Sliding internal doors appear in a variety of sliding door designs. The most modern sliding doors are stylistically fashioned after the sliding barn doors of yesteryear.

Sliding Barn Doors

Sliding barn doors are set apart from other types of sliding doors due to the type of sliding door hardware which is a major component of the design of the sliding barn doors. Sliding barn door hardware traditionally is on top of the door from which the sliding barn door hangs. Exposed wheels roll back an forth on an exposed track, which gives the impression of an old style rolling barn door, like you might have seen out in the country or in old movies, or TV shows depicting barns which featured this type of sliding barn door.

Though the architectural sliding door design features may vary depending on the presentation, as the sliding barn door surface material may have a rustic appearance, or a highly polished modern sliding barn door appearance, which may feature wood, or other more contemporary sliding barn door materials.

Sliding Wall

One of the most popular uses of an interior sliding door is the concept of the sliding wall, which is not unlike the sliding patio door design, but usually features a solid door facing which could be either wood or some type of metal, such as aluminum sliding doors or steel sliding doors, used as a method to provide insulated separation between adjoining rooms, or dividing a large space into two or more separate rooms, while still retaining the large space, when needed. In this case, sliding doors room dividers can be sliding internal doors, feature barn door sliders, or a combination of folding sliding doors, depending on the architectural specifications of the sliding partition wall units.

Wooden Sliding Doors

Wooden sliding doors are the most problematic doors due to Mother Nature’s wood grain’s tendency to move according to the environmental conditions within the proximity of the faces of the wooden sliding door. In this sense, the door can seem very alive as it tends to bend or cup. This is one of the primary benefits of featuring Sing Core inside any type of wooden sliding door because it’s the only known method of creating a strong, lightweight, solid core wooden sliding door that can be guaranteed not tio warp, bend, twist or otherwise fail for 50 years.

Warp-free Sliding French Doors

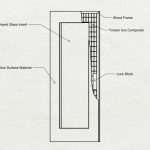

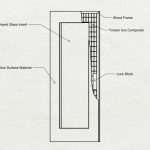

Sliding French Door Specs

The only known method for manufacturers of sliding French doors to create a warp-free sliding French door is to start with patented Sing Core’s insulation reinforced torsion box composite solid core material with patent pending warp-free technology to prevent the large oversize sliding door from failing for the service life of the wooden sliding doors, which would otherwise fail. Sing Core provides the sustainable Eco-friendly lightweight, high strength, torsion box composite technology to sliding door manufactures that can be guaranteed warp-free for 50 years.

A sliding door that moves can jeopardize the sliding door lock, making it difficult, if not impossible, to secure. Let’s face it, a door that cannot be secured, is not much of a door at all. While warp-free is a huge advantage of sliding doors with Sing Core inside, another benefit is huge savings in sliding door hardware and maintenance over time. See also: How to Build Large Non-warp Exterior Sliding Doors

Sliding Door Hardware

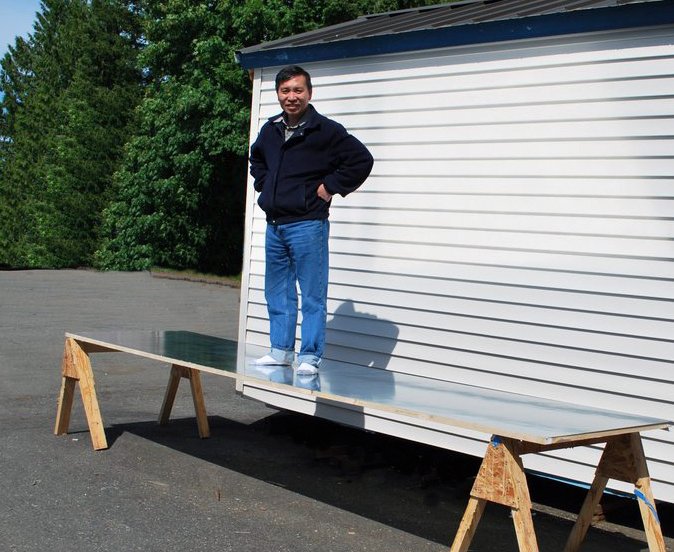

The weight of the sliding door determines the size and nature of the sliding door hardware to be used to accommodate the sliding door’s operation. Whether the doors operation is as an automatic sliding door, or manual sliding door operation, the sliding door mechanism and hardware must be suited to the weight of the door. For heavy sliding doors, the sliding door hardware could cost many times the cost of the sliding door itself, which includes the sliding door handles. Fortunately for sliding doors that have Sing Core inside, they weigh a fraction of the weight of other solid core doors, which accounts for being able to utilize lighter weight sliding door hardware to match the sliding door, which also reduces stress and strain on both the structure and the hardware over time saving time and money over the life of the sliding door.

Sliding Door Repair

Of all the materials with which a sliding door company could build a sliding door, Sing Core is the most sustainable Eco-friendly material made in the USA, and can easily be repaired on site. For instance, in commercial sliding door operations, heavy equipment could damage the door, such as being punctured by forklift forks. If the doors are made of other traditional core material, the entire door might have to be replaced. But if you have Sing Core inside, the door can easily be repaired without compromising the high performance, precision, strength, security or insulation qualities of your sliding door with Sing Core inside.