One of the most popular solutions for building a flexible trade show system has been the trade show truss displays. This has offered a degree or flexibility in altering the layout and design of a trade show booth that was unavailable in previous traditional trade show booth systems.

One of the most popular solutions for building a flexible trade show system has been the trade show truss displays. This has offered a degree or flexibility in altering the layout and design of a trade show booth that was unavailable in previous traditional trade show booth systems.

The popular conundrum in trade show design and management is that of lightweight and high strength. In most cases, the engineering and design staff will have to sacrifice either weight or strength having to choose one over the other depending on the expectations of the exhibitor.

This led to success of trade show truss systems that weigh less than a stick-based carpenter-built trade show display that would be disposed of following the trade show because it weighed less and could be knocked down and re-assembled for use in the next trade show event.

For many years the trade show truss system has set the standard for portable trade show displays; that is until Sing Core introduced the best trade show booths imbuing trade show engineers and designers with a whole new level of prolific design options without sacrificing due to the limitations of materials lacking in either lightweight or high strength.

The Best Trade Show Booths

The Best Trade Show Booths

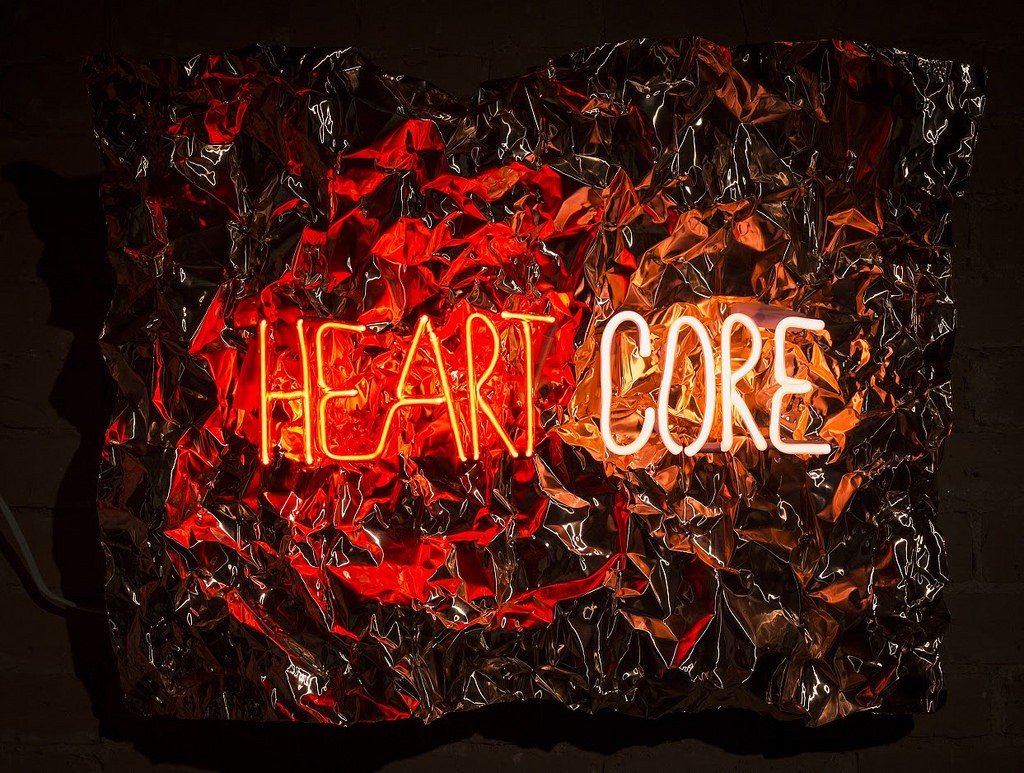

This new generation of trade show displays has made a decisive impact on trade shows and the trade show designers who are always on the lookout for leading edge trade show booth ideas. Imagine a modular building material that is lightweight yet stronger than steel (660 PSI) pound for pound, taking trade show design to a whole new level.

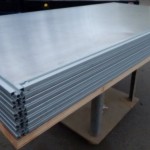

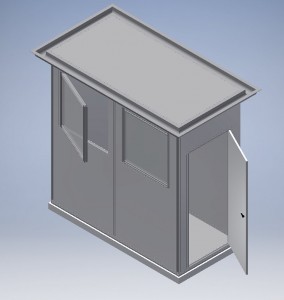

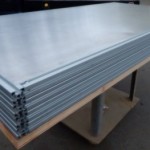

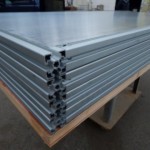

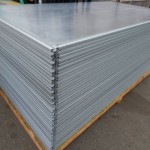

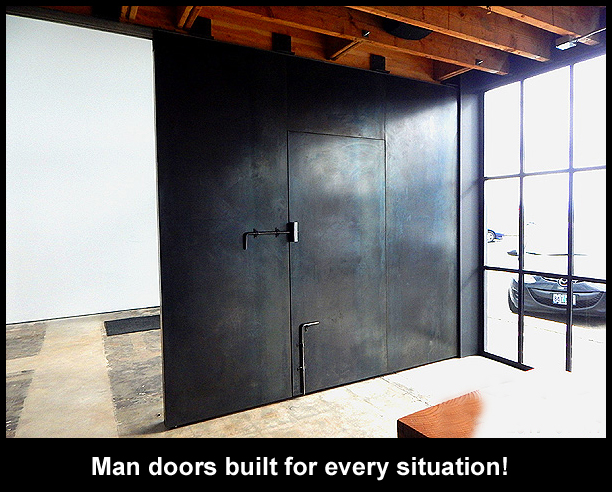

These exciting new components for portable trade show displays consisted of the most advanced high precision display panels that are also the key component used in making the best trade show tables, trade show flooring as well as trade show walls.

These new trade show booths were completely modular, could quickly and easily assembled, disassembled flat-packed, transported and stored ready for the next trade show. See a 70 ft. trade show display including two offices, assembled by one man in less than an hour. See the video.

But the technology did not stop there. The unbridled savvy trade show engineers and designers pressed Sing Core through to an even greater level of high precision composite technology…

T Slot Trade Show Booths

T Slot Trade Show Booths

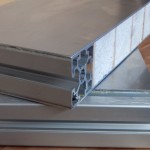

A staple in high-end industrial applications is the t slotted aluminum extrusion when enabled engineers and designers to create high precision projects. Still, with all the benefits of the aluminum t slot stiles and rails, the project could (and probably would) fail due to the instability of the other structure material that was weak or had the potential to warp, bend, twist, rot or otherwise fail over the lifespan of the project.

Sing Core is the secret ingredient in the most high performance t slot projects industry-wide. The lightweight high strength attributes in tandem with t slot empowered the most advanced architects specify the most complex components that would not have been able to meet the most stringent performance specifications.

It was no surprise to see this new technology spill over into trade show booth design, which faced the same design limitations of trade show truss displays.

Now, trade show designers are able to use the most sophisticated modular trade show structure system to build the ultimate trade show booths, including multiple stories and mezzanines that are lightweight, high strength and can be guaranteed not to warp, bend, twist or otherwise fail for 50 years!

If you’re ready to have the best award winning trade show booth at your next presentation, contact us, for more information.

- T Slot Beams