10×10 Trade Show Booth

Item # 10x10D

The 10x10D trade show kit is exactly like the 10x10A kit, but features 1 36-inch and 2 20-inch front display panels (instead of only 20-inch front panels).

10x10D Parts List

Optional

|

|

The 10x10D trade show kit is exactly like the 10x10A kit, but features 1 36-inch and 2 20-inch front display panels (instead of only 20-inch front panels).

10x10D Parts List

Optional

|

|

The 10x10C trade show kit is exactly like the 10x10A kit, but features 2 36-inch and 2 20-inch front display panels (instead of only 20-inch front panels).

10x10C Parts List

Optional

|

Wooden sliding doors are the most sought out sliding doors in the marketplace today. Increasingly, among contemporary architecture design the latest designs feature not only wooden sliding doors, but wooden sliding doors that are larger in size. Even though these large wooden sliding doors are highly sought after, the nature of the natural wood in wooden sliding doors does present some challenges.

While we all appreciate the natural beauty of wood, the fact remains that this material comes from a living tree and naturally adorned with grain that is unique to each variety of tree giving it the elegant design feature of natural wood grain. The nature of the wood grain when we are so drawn to is also the most problematic feature when trying to create a sliding door which can remain straight enough to function properly. Natural wood grain, while it appears to be elegant in every way, moves as if the tree were still alive. In the sliding door industry sliding door manufacturers and those servicing sliding door accounts, there are specific words used to describe the conditions of wooden sliding doors when they fail, such as warp, bend, twist and cup.

While we all appreciate the natural beauty of wood, the fact remains that this material comes from a living tree and naturally adorned with grain that is unique to each variety of tree giving it the elegant design feature of natural wood grain. The nature of the wood grain when we are so drawn to is also the most problematic feature when trying to create a sliding door which can remain straight enough to function properly. Natural wood grain, while it appears to be elegant in every way, moves as if the tree were still alive. In the sliding door industry sliding door manufacturers and those servicing sliding door accounts, there are specific words used to describe the conditions of wooden sliding doors when they fail, such as warp, bend, twist and cup.

Due to the nature of wood to warp, the AWI standard allowable warp for a door up to seven feet tall is a quarter of an inch of warp. ¼ inch warp in a 7 ft. door is considered a straight door. For wooden sliding doors over 7 ft. there is no limit to acceptable warp due to the nature of natural wood and its tendency to move subject to changes in the environmental conditions on either side of the door. The most problematic wooden sliding doors are exterior sliding doors because one side faces indoors, while the other side faces the elements. Interior doors have fewer problems with sliding door warp, but if they are over 7 ft. tall, will continue to present problems with sliding door warp.

The weight of natural wood is another issue to take into consideration when entertaining the idea of including a large wooden sliding door in your project’s design. Heavy wooden sliding doors will create added expenses very early on in the inclusion process, such as the added cost of shipping and handling. Moving the door from point A to point B will incur expenses based on the wooden sliding door’s weight. After the heavy sliding door arrives on the job site, installers must manhandle the door, and use heavy equipment to help maneuver the door on site. Additionally, a heavy wooden sliding door will require heavy duty sliding door hardware, which may cost many times more than the wooden sliding door itself.

Large wood sliding doors vibrate, like a speaker, transferring sound from one side of the door to the other, which may not be a problem if your location is in the remote wilderness. Besides sound transfer, loss of energy is significant as wood is unable to maintain climate separation from one side of the door from the other, which is also many times more problematic for exterior sliding doors or doors separating two spaces that may have separate activities occurring on either side (such as office, meeting or recreational spaces).

The true flat team at Sing Core has a proven track record of providing warp-free sliding door solutions of any size (up to 50 ft.) based on its patented reinforced torsion box composite core and patent pending stiffener and straightening technology that enable them to make the only large sliding doors that can be guaranteed not to warp, bend twist or otherwise fail (including full structure warranty) for 50 years.

The true flat team at Sing Core has a proven track record of providing warp-free sliding door solutions of any size (up to 50 ft.) based on its patented reinforced torsion box composite core and patent pending stiffener and straightening technology that enable them to make the only large sliding doors that can be guaranteed not to warp, bend twist or otherwise fail (including full structure warranty) for 50 years.

Wooden sliding doors with Sing Core inside are the most dimensionally stable Eco-friendly lightweight and high strength (660 PSI, stronger than steel pound for pound) sliding doors made in the United States of America.

Thanks to the Sing wooden sliding door solution, wooden sliding doors can be made lightweight without compromising strength. Hollow core doors are lightweight but are relatively useless and insecure but better than leaving the doorway empty. A lightweight door does not have to be weak, thanks to patented Sing technology that enables door manufactures to create a lightweight door that is stronger than any other known door core material, and weighs a fraction of the weight of any other solid core wood-based material.

The patented Sing Core wooden sliding door solution creates a one-of-a-kind sliding door that is as unique as your thumbprint. Every Sing wooden sliding door is an individual work of art, specially designed and built to meet or exceed architectural specifications, regardless of size or applications. One of the unique attributes of the patented Sing torsion box core is that it is pre-insulated. The empty spaced of the torsion box voids are insulated which imbues the wooden sliding door with characteristics of an insulated sliding door that offers climate control R-vale and well as sound dampening.

Your patented Sing wooden sliding door solution can be applied to any type or style of wooden sliding doors, including but not limited to the following sdoors made of any kind of natural wood or any available wood-based skin material:

| Sliding Front Door | Sliding French Doors | Sliding Security Doors |

| Sliding Wardrobe Doors | Sliding Barn Doors | Sliding Double Doors |

| Sliding Patio Doors | Internal Sliding Doors | Automatic Sliding Doors |

| Sliding Room Dividers | Sliding Barn Style Doors | Sliding Interior Doors |

| Sliding Wall Systems | Exterior Sliding Doors | Sliding Doors Room Dividers |

| Barn Door Sliders | Hangar Doors | Sliding Pocket Doors |

| Sliding Folding Doors | Hanging Sliding Doors | Modern Sliding Doors |

| Sliding Patio Doors | Kitchen Sliding Door | Large Sliding Doors |

| Custom Sliding Doors | Sliding Panel Doors | Commercial Sliding Doors |

| Sliding Partition Doors | Steel Sliding Doors | Triple Sliding Door |

| Multi Slide Doors | Concealed Sliding Doors | Sliding Front Door |

| Sliding Back Doors | Sliding Restaurant Doors | Sliding Industrial Doors |

These revolutionary warp-free wooden sliding doors can be made of different types of wood to make the strongest wooden sliding doors that can be guaranteed not to warp, bend, twist and remain structurally sound for 50 years. You can have the following warp-free wooden sliding doors with Sing Core inside:

| Ash Wood Sliding Doors | Beech Wood Sliding Doors | Birch Wood Sliding Doors |

| Cedar Wood Sliding Doors | Cherry Wood Sliding Doors | Fir Wood Sliding Doors |

| Fruitwood Wood Sliding Doors | Hard Rock Maple Sliding Doors | Hemlock Wood Sliding Doors |

| Hickory Wood Sliding Doors | Knotty Pine Wood Sliding Doors | Mahogany Wood Sliding Doors |

| Maple Wood Sliding Doors | Oak Wood Sliding Doors | Pine Wood Sliding Doors |

| Port Orford Cedar Sliding Doors | Red Cedar Wood Sliding Doors | Red Oak Wood Sliding Doors |

| Rosewood Wood Sliding Doors | Spruce Wood Sliding Doors | Sugar Maple Wood Sliding Doors |

| Teak Wood Sliding Doors | Walnut Wood Sliding Doors | White Oak Wood Sliding Doors |

… Just to name a few, as warp-free Sing wooden sliding doors can feature any wood surface, including rare, exotic wood(s) when available.

Patented Sing Core solid wood stave sliding door blanks feature the newest technology in the door industry for composite sliding doors yielding the only eco-friendly, lightweight, fully insulated, high-strength sliding doors with wood blanks of any size (up to 40 ft.) that can be guaranteed true flat and to stay flat for 50 years.

Large sliding door versus regular-size sliding door challenge (i.e., over 4 feet wide and over 8 feet in length):

Large sliding doors are heavy, dimensionally unstable, require more strength due to the heavy weight, and are a challenge to manufacture, ship and install. High-end jobs require precision and true flatness to please the customer. A homeowner’s architect, general contractor and mill worker must solve the problem of warped sliding doors. The solution to the challenge is to use patented professional Sing door blanks to make your sliding doors.

Large sliding doors are heavy, dimensionally unstable, require more strength due to the heavy weight, and are a challenge to manufacture, ship and install. High-end jobs require precision and true flatness to please the customer. A homeowner’s architect, general contractor and mill worker must solve the problem of warped sliding doors. The solution to the challenge is to use patented professional Sing door blanks to make your sliding doors.

Sing Core wood stave door blanks help door manufacturers to create the only solid wood sliding doors that will not warp, bend, twist or cup following installation. This means no more continuous service calls for maintenance of big sliding doors that cannot possibly stay straight due to the limitations of solid wood – or any other sliding door core – that is subject to failure. Sing sliding door blanks have a patented honeycomb/torsion box interior which gives lightweight yet unsurpassed strength (pound-per-pound stronger than steel) and stability to any door, and allows Sing Core to provide a 50-year guarantee

Sing sliding door blanks make amazing designer doors in any style. With Sing sliding door core, fragile sliding doors such as French doors are made lightweight yet strong, not warping or breaking hinges, which will last for many decades.

Sing sliding door blanks make sturdy exterior doors in any style. With Sing sliding door core, exterior sliding doors are lightweight and strong, even when oversized. Our professional wooden sliding doors are guaranteed to stay true flat and not warp or twist for 50 years

The problem is that all sliding door core materials are either not high precision, too heavy or will move when exposed to moisture, humidity or change in temperature resulting in sliding door failure.

The problem is that all sliding door core materials are either not high precision, too heavy or will move when exposed to moisture, humidity or change in temperature resulting in sliding door failure.

Heavy solid metal or steel will not warp, bend or twist, but is not high precision due to welding (sing core tolerance is + or – .006 inch!) and is often impractical due to the overweight issues causing excess strain on both the hardware and structure, causing continued maintenance issues. The solution is our patented lightweight yet strong Sing core wooden sliding door technology.

Finishing a wooden sliding door blank:

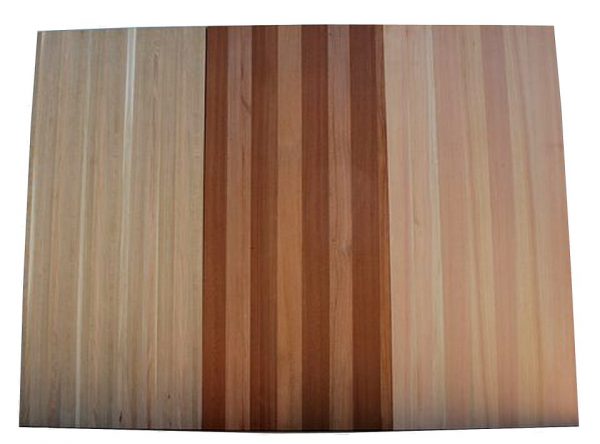

There are two types of finish for door blanks: paint grade and wood grain. Paint grade includes such finishes as domestic and marine plywood, etc. Wood grain finish includes such finish as solid wood stave and/or thin veneer.

Why Use Solid Wood Instead of Veneer?

Never settle for substandard veneer sliding doors again. Door engineers prefer to use inexpensive veneer as opposed to real solid wood facings because veneer is thought to be less likely to warp, bend or twist. But thanks to the super-strength of patented Sing Core technology, you can use solid wood stave and wood blanks with confidence knowing that your wooden sliding door can be guaranteed true flat and will stay flat.

How can a solid wood-faced sliding door stay true flat? As every woodworker knows, when using a solid wood surface, the grain will move according to moisture or temperature change causing the door to fail. When using our patented Sing Core as a substrate you can safely use solid wood because the patented solid torsion box composite material is continually keeping the wood grain straight and true. Whereas wood stave has more wood fiber giving it more of a chance to warp than thin veneer due to the unbalance of the both side of the door moisture contents, patented Sing technology solves this problem by combining patent pending stiffening materials throughout our Sing core. This warp-free Sing wooden sliding door technology eliminates the troublesome movement of the sliding door blank — warping is no longer a concern when wood stave is combined with reinforced patented Sing core.

- Walnut

- Marine Grade Ply

- Bi-directional Walnut

In addition, solid wood is easy to work with, install (no need to hot press), repair and remodel. That’s why professionals trust Sing Core’s years of expertise in helping to design the only wood stave sliding doors (that look just like solid wood sliding doors) that can stay straight and true for many decades while respectfully honoring the beauty and elegance of solid wood, which far outlasts easily-damaged veneers, yet can be sanded and repaired if necessary.

Celebrate your real wood!

Our Eco-friendly lightweight, high strength alternative is the best solution for combating the issues associated with weight and size, especially large doors. Only our patented Sing torsion box/foam composite core combined with our years of experience provides guaranteed solutions for oversize sliding doors.

Our Eco-friendly lightweight, high strength alternative is the best solution for combating the issues associated with weight and size, especially large doors. Only our patented Sing torsion box/foam composite core combined with our years of experience provides guaranteed solutions for oversize sliding doors.

That’s why this technology is found everywhere, from beneath the sea (US Navy) to outer space (NASA) and everywhere in-between.

Sing sliding door blanks may be made using almost any wood species, like mahogany, redwood, teak wood, cherry wood, walnut wood, cedar wood, Ipe wood, sapele wood, poplar wood, ebony wood, ash wood, oak or any other hardwood or exotic wood types available.

This same wood sliding door blank composite technology is also a common solution for high-end projects like engineered hardwood flooring, shiplap, wood furniture, wood shelves, decking, shed doors or any other application demanding high precision and exemplary performance over time.

As an alternative to wood stave, domestic wood grain plywood could be used to create a nice wood grain surface, even for large sized wooden sliding door applications.

How is wood stave/veneer added to Sing panels?

Years in the making, finally Sing Core has come out with the ultimate solution for Eco-friendly pivot doors made of any material and any size weighing a fraction of other door cores. This revolutionary patented solution has made Sing Core the number one resource for large pivot doors that are lightweight, high strength and can be guaranteed to remain warp-free for 50 years, as well as full structure warranty. No other large pivot door solution can match the power of Sing Core. Here’s the latest straight talk about pivot doors:

As the demand for large pivot doors is on the increase, the bigger they are, the more impressive they are, also, the more apt they are to fail due to door warp. Let’s face it, a door that is not straight and true is of little use as a door at all.

It is imperative for large pivot doors to remain straight and true, and the design team at Sing Core has created a full battery of patented and patent pending solutions to keep any large pivot door, made of any material perfectly straight, far exceeding AWI standards for flatness. The true flat experts at Sing Core have the knowledge and ability to create large pivot doors will not warp, eliminating the biggest complaint about pivot doors.

So, if you want a straight pivot door, the only way to get one made and guaranteed to remain warp-free for 50 years is to do what most contemporary architects, designers and engineers do, and that’s to specify that you want your doors to have, “Sing Core inside.”

Large pivot doors with Sing Core inside also solve other problems facing architects and designers, including, but not limited to…

Large pivot doors are big and heavy in weight. The large size and the heavy weight is problematic for a number of reasons. First of all, you must find a custom door manufacturer or millwork to take on such a project in the first place. Anything that is large is going to be difficult to create and manipulate through the building process just to create the mammoth door in the first place. Then you have to be able to move the door from the factory to the truck, using a combination of manpower and heavy equipment. Then transport the large pivot door from the factory to the job site. Once at the site, more manpower and heavy equipment is required to unload and move the door to where it will be installed. Installers now have to deal with the door, moving and fine tuning it to fit the space and attach the appropriate heavy duty pivot door hardware which can cost many times the price of the pivot door.

Expensive heavy duty pivot door hardware is required as the hardware is determined by the weight of the door. Even though this hardware is designed to handle a heavy weight pivot door, the straight talk is, if the door is used regularly, the hardware will start to breakdown and fail over time.

Which brings us to maintenance on the large pivot doors; yes, your large pivot door is impressive and leaves a great first impression but the more consistent lasting impression is left upon the pivot door’s owner who must bear the cost of constant repair and maintenance over the life of the otherwise magnificent large pivot door. As huge pivot doors are used, they cause stress and strain, not only on the hardware, but also the structure, creating the need for maintenance and repair on the pivot door for warp, the hardware as it deteriorates, and the structure for stress and strain.

In most large pivot doors, little thought is given to the insulation value of the door. While large pivot doors are commonly thicker than their hinged cousins, the large pivot doors may not provide for energy efficient handling of thermal separation or elimination of sound penetration.

If you have a large pivot door, operating it may be problematic, especially when delicate little fingers are around when the pivot door is opened and closed. Large pivot doors are so heavy that there is the danger of injury to anyone, not just children, when the doors are in motion.

Thanks you Sing Core, you can save money and have a better large pivot door experience over time, as the Sing solution is applied. Here are some of the solutions you can expect by specifying that your pivot door has, “Sing Core inside.”

If your pivot door is built with Sing Core inside, it can weigh a fraction of the weight of any other solid core pivot door. The energy savings in just the creation and transport of your Sing pivot door help to make it more ecologically responsible, using less energy to create, ship and handle. But there’s more…

Because the type of pivot door hardware is based on the pivot door’s weight, a lighter weight door requires a pivot hinge which is matched. Real cost savings can be realized by being able to use the less expensive pivot door hardware, bring the cost of the hardware way down.

Your Sing pivot door is very strong as it was university-tested and rated at 660 PSI in strength, making it stronger than steel pound for pound. This superior strength is due to the patented insulated reinforced vertical grain torsion box core. Without Sing Core inside , you are limited to the ability of the material used to maintain the pivot door integrity over time.

When your pivot doors have sing Core inside they are also nearly free of regular maintenance. If you have a professional Sing pivot door that does not warp, then you possess a large pivot door which can be guaranteed not to warp, bend, twist, cup, or otherwise fail for 50 years. Plus, if the door is damaged for any reason, it can be quickly and easily repaired on site (often without have to dismantle or remove the door) without compromising the pivot door’s strength or integrity. In addition, the lightweight of your Sing pivot door, means much less stress and strain on the hardware.

Being so lightweight reduces costs and time by being so lightweight. Due to the bulky size several people will need to manipulate the door, but no heavy equipment will be needed because the crew can easily maneuver the large pivot door without much trouble. In fact, we commonly hear back from the installers about how they couldn’t believe how light and easy to work with large pivot doors with Sing Core inside are.

Sing Core pre-packs your large pivot door with insulation wall to wall inside the torsion box structure imbuing your large pivot with increased ability for climate control and also sound deadening capabilities that are hard to find in other large pivot doors. If you’re thinking about separation between room, or particularly a pivot front door, the added insulation factor is of huge benefit and included in every Sing pivot door blank at no extra charge. Insulation upgrades are available per your specification.

Due to the increased insulation and high strength of your pivot door that has Sing Core inside, you can enjoy a greater sense of safety and security. The high strength will prevent breaching the door from unwanted guests. These are often used as impact doors. If you kick other lightweight pivot doors, they could easily fail and offer egress to an otherwise secure environment, but if you kick a Sing pivot door you will not break the door. You are more likely to break your leg and the sound deadening characteristics inhibits eavesdropping.

In the event a child, or anyone, gets their hand or fingers caught in a Sing large pivot door in motion, the likelihood of surviving such an event is much more likely as less damage will occur thanks to the Sing solution being so much lighter in weight than other large pivot doors.

Sing Core started the flat pack home revolution where entire homes were built of flat pack Sing Core products, including the foundation, floors, walls, doors, ceilings, roofs and all the interior furnishings. It’s no surprise that Sing Core would be the revolutionary patented building material to redefine the flat pack collapsible furniture industry.

Why? It’s all about the characteristics intrinsic in the nature of Eco-friendly Sing Core, attributes like:

While Ikea first introduced their idea of collapsible and flat packed furniture in the 1950s, Ikea has certainly created a market that they alone dominated. Only thing is, what do you think the biggest complaint is about Ikea’s collapsible furniture? You know it’s that it does not last. And what should you expect? They keep the prices so low, that you can’t possibly think of Ikea furniture as being anything but disposable (10% of all dollars spent on furniture ends up in Ikea pockets).

While Ikea first introduced their idea of collapsible and flat packed furniture in the 1950s, Ikea has certainly created a market that they alone dominated. Only thing is, what do you think the biggest complaint is about Ikea’s collapsible furniture? You know it’s that it does not last. And what should you expect? They keep the prices so low, that you can’t possibly think of Ikea furniture as being anything but disposable (10% of all dollars spent on furniture ends up in Ikea pockets).

When Ikea furniture breaks down no one complains, they just send the pieces off to the landfill, while they spend a few dollars to replace the broken down garbage, and no one bats an eye, except for the socially conscious individual who sees there is no sense of sustainability, when disposable Ikea furniture is posing almost as much negative eco energy as the plastic water bottle. Where is the social responsibility?

Sing Core proposes creating the same type of collapsible furniture with modular components that can be redesigned and repurposed on the fly, where all parts are interchangeable and may interconnect and the pieces are nearly indestructible, designed to last forever.

The lightweight and stronger-than-steel characteristics of patented Sing Core make it to perfect material to build modular, collapsible furniture, which can be flat packed for transport or storage, using far less energy to create, ship, assemble, disassemble and maintain with unparalleled longevity. In fact, professional Sing Core is designed to last virtually forever and comes backed with an unprecedented 50 year warp-free, fail-free guarantee.

The lightweight and stronger-than-steel characteristics of patented Sing Core make it to perfect material to build modular, collapsible furniture, which can be flat packed for transport or storage, using far less energy to create, ship, assemble, disassemble and maintain with unparalleled longevity. In fact, professional Sing Core is designed to last virtually forever and comes backed with an unprecedented 50 year warp-free, fail-free guarantee.

Even though it is a more expensive hand-made process that is the basis of Sing Core’s reinforced insulated torsion box composite material, the result is far superior to any known lightweight building material.

No lightweight building material available (even aerospace core materials) is stronger and impact resistant for improved longevity. If a Sing Core furniture component is damaged, it does not need to be replaced; it can be repaired and may not even need to be disassembled to be repaired.

This is how Sing Core dominated the large door industry. Large doors could now be made lightweight, super strong and able to last for years, without warping or failing structurally. This was unheard of in the large door business, as all door manufacturers know, “All large door will warp and fail.” So, they are not covered by any warranty, this is, unless they have, “Sing Core inside,” enabling them to be fully guaranteed for 50 years.

This is how Sing Core dominated the large door industry. Large doors could now be made lightweight, super strong and able to last for years, without warping or failing structurally. This was unheard of in the large door business, as all door manufacturers know, “All large door will warp and fail.” So, they are not covered by any warranty, this is, unless they have, “Sing Core inside,” enabling them to be fully guaranteed for 50 years.

Collapsible, flat pack Sing furniture is the socially and ecologically sensible and sustainable answer to the disposable furniture purveyors burying our cities in waste.

The Sing modular furniture components are interchangeable and reusable. In fact, there are negotiations going on with the inventor proposing free standing big box stores warehousing the various components. In this scenario, the customer comes into the store, identifies an assembled piece of furniture, the store associate goes to the warehouse, pulls the components from a parts-list and packages them into a flat pack for the customer.

No modular furniture design is so simple and convenient with long lasting results of sustainability and functionality. Is your family expanding, no problem, you can buy the components to expand your double-bed into a king sized bed, your crib into a twin-size bed, your coffee table into a dining room table, your end tables into a sofa, your end tables into a kitchen island, the possibilities are endless.

No modular furniture design is so simple and convenient with long lasting results of sustainability and functionality. Is your family expanding, no problem, you can buy the components to expand your double-bed into a king sized bed, your crib into a twin-size bed, your coffee table into a dining room table, your end tables into a sofa, your end tables into a kitchen island, the possibilities are endless.

To be able to go to the Sing Big Box Store and go home with an entire bedroom set in the back seat of your car is a dream come true, and you can’t believe the number of college students already beginning to line up for the single-purchase dorm furniture that will knock down and follow them home, into their offices or dens as they launch their careers. It’s all happening.

Having a wedding or event in your back yard? No problem, you have all the folding table and chairs you could possibly need flat packed and stored in the back of your closet or wardrobe. Any of these components can be easily assembled without expensive tools or carpentry skills, and quickly disassembled in as little time, and flat packed again for easy storage.

Not long ago, the trade show industry took a great interest in the Sing Core building material. Trade shows are inherently wasteful, in that trade show displays and booths are constructed, demolished and disposed of, wasting millions of dollars at each show. Due to the long life and structural integrity of the patented Sign Core material, trade show vendors were now able to use and reuse the individual modular trade show display components over and over again.

Not long ago, the trade show industry took a great interest in the Sing Core building material. Trade shows are inherently wasteful, in that trade show displays and booths are constructed, demolished and disposed of, wasting millions of dollars at each show. Due to the long life and structural integrity of the patented Sign Core material, trade show vendors were now able to use and reuse the individual modular trade show display components over and over again.

What’s more, is that due to the modular nature of the design elements of the individual trade show components, if your business expanded your trade show system could now expand with you. Before Sing Core, if your business grew from a 10 x 20 trade show booth to a 10 x 70 trade show display, it meant getting a whole new outfit, when with Sing Core trade show components, all you need to do is add the components necessary to accommodate your new design (and be able to assemble it in minutes).

You can see how this translates well to the modular collapsible flat pack furniture division of Sing Core.

Apartment managers are thrilled of the idea of storing the furnishings for a hundred units in one storage room, then assembling what they need on-the-fly, making the option of providing a fully furnished apartment, instead of an unfurnished apartment a snap, adding the furnishings to the monthly revenue stream.

Putting together modular Sing Furniture is as easy as connecting Legos. Unlike other flat pack systems that come with a variety of parts and connectors, modular Sing furniture components are designed to lock in and easily assemble, not unlike the trade show system Sing Core is so renowned for.

Instead of an average 2-hour assembly time, your Sing modular components can be connected in minutes, without special tools or equipment, like this collapsible dresser.

Stop thinking that collapsible flat pack furniture means disposable. You can have all the advantages and chic elegance that comes from having a high quality piece of furniture that can easily be disassembled and/or repurposed, stored and/or transported.

Stop thinking that collapsible flat pack furniture means disposable. You can have all the advantages and chic elegance that comes from having a high quality piece of furniture that can easily be disassembled and/or repurposed, stored and/or transported.

This is not disposable furniture, as you may have thought of before; this new evolution of collapsible flat pack furniture is spearheading a revolutionary concept in sustainable modular furniture for generations to come. In fact, you will find Sing Core in some of the most high end, multi-million-dollar homes (like this 48 million dollar home) and mansions. If it’s good enough for the elite, you will be proud to have this very same material in your own abode.

This new concept of simple, yet elegant, highly functional, expandable and adaptable new line of modular furniture is redefining the flat pack definition.

Whether you’re a high functioning apartment dweller, a space conscious home owner or a college student on-the-run, Sing modular collapsible flat pack furniture is empowering you to propel your space conscious sustainable future.

No to be confused with flimsy flat pack furniture of yesteryear, this new material is extremely strong in comparison. For instance an Ikea component may have compression strength of 10 PSI, whereas Sing Core clocks in at an impressive 660 PSI, stronger than steel pound for pound.

Now you can have all the convenience of knock down component furniture without the risk of being disposable or failing over time. It won’t matter whether your packing up your folding table, folding chairs, flat pack furniture, space saving beds or any other space saving furniture, Sing Core has you covered.

Whether it’s your home, or any or all of its furnishings, you can have it all flat packed thanks to Sing Core.

Flat Pack Bookshelves Collapsible

General Specifications

Sing Core Professional Large Trapezoid Pivot Door Blanks are 40 ft. tall,18 ft. wide at the top 12 ft. wide at the bottom, and 3.5 in. thick and manufactured utilizing patented Sing Core material as the base interior substrate of the door. Size to be adjusted to varying specifications. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is recycled EPS foam. Natural wood lock blocks can be positioned at locations as necessary for locking mechanism placement and/or as pivot hardware anchor points. The core material is framed by 1.25-inch wood stiles and rails for finishing strength and attaching hardware. The torsion box is completed by adhering .25 in. marine grade birch paint grade ply as exterior material (skin) or other material according to your specifications.

1/4 in. Marine Grade Birch Ply Pivot Door Stress Skin

The trapezoid pivot door blank surface material is made of .25″ marine grade birch ply paint grade stress skin unless otherwise specified. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Click here for tips on How to Create the Right Sing Panel for your specific project.

Every Sing Core manufactured trapezoid pivot door blank is unfinished (unless specified otherwise) and professional grade is guaranteed for 50 years for warp-free and structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the Sing Core trapezoid pivot door blank is intended for use in:

Large Trapezoid Pivot Door Materials: Sing Core large trapezoid pivot door blanks are manufactured using Eco-friendly cold-press process. Composite materials include:

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foamArchitectural Specifications Substitutes

For information on some of our architectural substitutes click here.

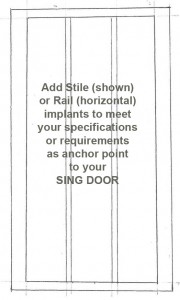

Interior Blocking: Solid wood implants can be inserted as lock blocks or anchor points. Also additional stiles (vertical wood implants) or rails (horizontal wood implants) can be positioned at any desired location inside the large trapezoid pivot door. (Note: Depending on your expectations, solid wood implants should be supported by at least 12 inches of Sing Core material to maintain true flatness.)

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core large trapezoid pivot door from factory to your location including proper crating to protect the natural beauty of your pivot doors during transport.

Storage and Protection: Store your Sing Core large trapezoid pivot doors in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that openings or attachment walls are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

Verify that attachment, hinging and latching assemblies operate freely and correctly

Finishing: The finishing of the Sing Core large trapezoid pivot doors are the responsibility of the client due to the product being delivered in unfinished condition unless specified otherwise in writing for use in interior applications only. Any exterior use must be approved in advance to avoid warranty exception and sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary. In reference to exterior applications:

Machining: Sing Core large trapezoid pivot doors are easy to work with in the millwork or standard woodworking shop for CNC work or on-site for finishing, and fastening.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Sing Core large trapezoid door pivot blanks feature built-in insulation value with an R3 (can be upgraded to to R6.5 or more) rating per inch, depending on architect’s specifications.

Acoustical Performance: Sing Core trapezoid pivot door blanks have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30*. Additional noise control specifications can be met at the behest of the customer or designer and must be noted in advance.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean wood fiber and/or recycled material.

Warranty: Sing Core professional large trapezoid pivot door blanks can be structurally guaranteed and warp-free for 50 years under normal conditions.

Basic Sing Door Spec Drawings: Click here

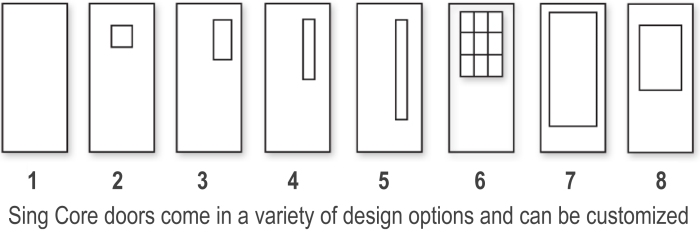

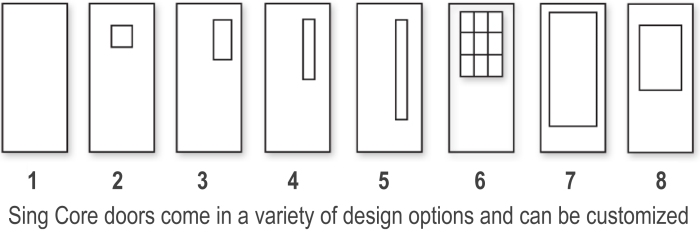

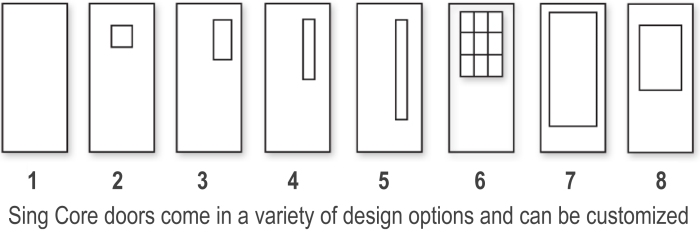

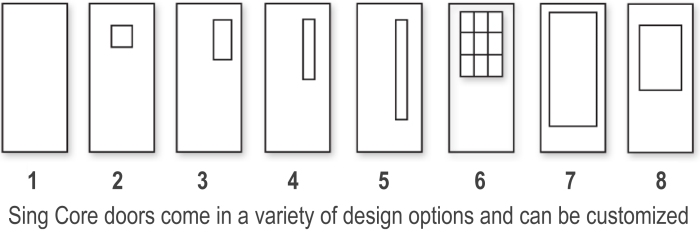

Custom-cut Window/Lite Openings: Lite openings for glass inserts can be custom cut per your specifications (drawings above show examples of standard openings) for glass insertion.

Door Specifications |

||

Door Width |

Rough Opening Width |

Rough Opening Height 6/8 |

| 2/0 (Single) | 26″ | 82-1/2″ |

| 2/4 (Single) | 30″ | 82-1/2″ |

| 2/6 (Single) | 32″ | 82-1/2″ |

| 2/8 (Single) | 34″ | 82-1/2″ |

| 3/0 (Single) | 38″ | 82-1/2″ |

| 4/0 (Double) | *50″ | 82-1/2″ |

| 4/8 (Double) | *58″ | 82-1/2″ |

| 5/0 (Double) | *62″ | 82-1/2″ |

| 5/4 (Double) | *66″ | 82-1/2″ |

| 6/0 (Doulble) | *74″ | 82-1/2″ |

See also: Door Technical Information

Appearing regularly in Contemporary Architecture Design

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.

General Specifications

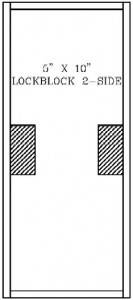

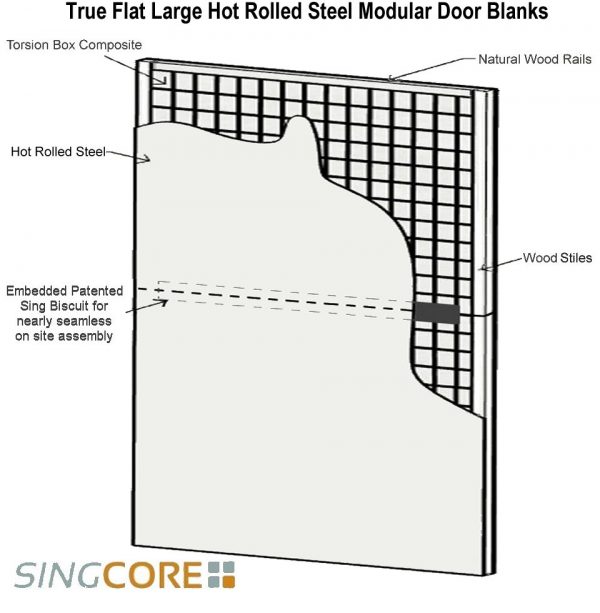

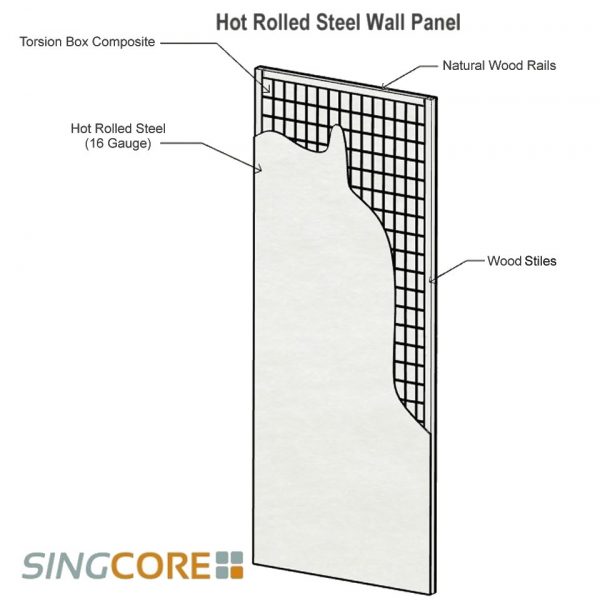

Standard Sing Core Hot Rolled Steel Door Blanks are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is recycled EPS foam. Natural wood lock blocks can be positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is framed by 1.25-inch wood stiles and rails for finishing strength and attaching hardware. The torsion box is completed by adhering hot rolled steel as exterior material (skin) according to your specifications.

Standard Sing Core Hot Rolled Steel Door Blanks are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is recycled EPS foam. Natural wood lock blocks can be positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is framed by 1.25-inch wood stiles and rails for finishing strength and attaching hardware. The torsion box is completed by adhering hot rolled steel as exterior material (skin) according to your specifications.

Hot Rolled Steel Door Surface Material

The door blank surface material is made of hot rolled steel unless otherwise specified. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Click here for tips on How to Create the Right Sing Panel for your specific project.

Every Sing Core manufactured door blank is unfinished (unless specified otherwise) and professional grade is guaranteed for 50 years for warp-free and structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the standard Sing Core door blank is intended for use in:

Hot Rolled Steel Door Materials: Sing Core hot rolled steel door blanks are manufactured using Eco-friendly cold-press process. Composite materials include:

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam

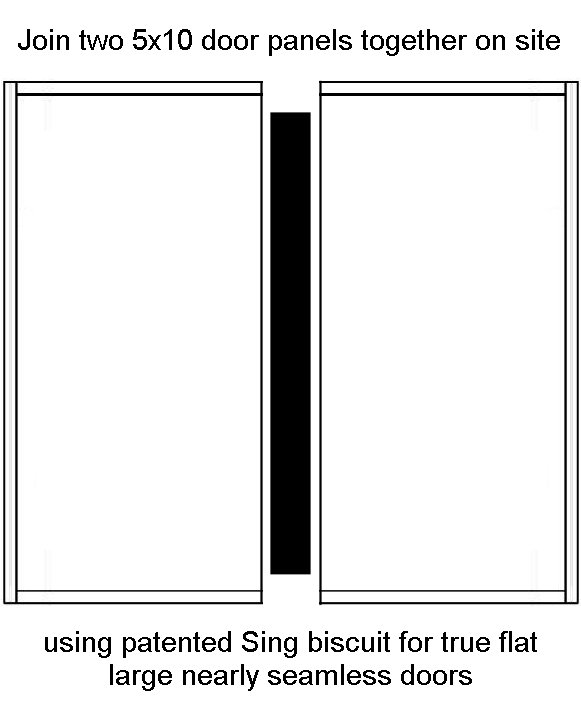

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foamLarge Door Component Assembly: The largest doors (see 10×10 example drawing tot he right) may not be easily transported from the factory to the job site. In cases such as these doors are divided into two or more modular components and joined together on site using patented Sing biscuit joining method. This method results in a near seamless joining of two or more door blanks without compromising flatness or structural integrity.

Architectural Specifications Substitutes

For information on some of our architectural substitutes click here.

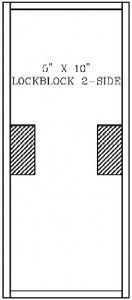

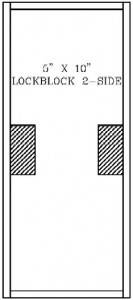

Interior Blocking: Solid wood implants can be inserted as lock blocks or anchor points. Also additional stiles (vertical wood implants) or rails (horizontal wood implants) can be positioned at any desired location inside the hot rolled steel door. (Note: Depending on your expectations, solid wood implants should be supported by at least 12 inches of Sing Core material to maintain true flatness.)

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core hot rolled steel door from factory to your location including proper crating to protect the natural beauty of your hot rolled steel doors during transport.

Storage and Protection: Store your Sing Core hot rolled steel doors in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that openings or attachment walls are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

Verify that attachment, hinging and latching assemblies operate freely and correctly

Finishing: The finishing of the Sing Core standard hot rolled steel doors is the responsibility of the client due to the product being delivered in unfinished condition unless specified otherwise in writing for use in interior applications only. Any exterior use must be approved in advance to avoid warranty exception and sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary. In reference to exterior applications:

Machining: Sing Core hot rolled steel doors are easy to work with in the metal shop for machining or on-site for finishing, and fastening.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Standard Sing Core door blanks feature built-in insulation value with an R3 (can be upgraded to to R6.5 or more) rating per inch, depending on architect’s specifications.

Acoustical Performance: Sing Core standard wall panels have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30*. Additional noise control specifications can be met at the behest of the customer or designer and must be noted in advance.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean wood fiber and/or recycled material.

Warranty: Sing Core standard door blanks come with a 10-year warranty, while professional manufactured door blanks can be structurally guaranteed and warp-free for 50 years under normal conditions.

Basic Sing Door Spec Drawings: Click here

Custom-cut Window/Lite Openings: Lite openings for glass inserts can be custom cut per your specifications (drawings above show examples of standard openings) for glass insertion.

Door Specifications |

||

Door Width |

Rough Opening Width |

Rough Opening Height 6/8 |

| 2/0 (Single) | 26″ | 82-1/2″ |

| 2/4 (Single) | 30″ | 82-1/2″ |

| 2/6 (Single) | 32″ | 82-1/2″ |

| 2/8 (Single) | 34″ | 82-1/2″ |

| 3/0 (Single) | 38″ | 82-1/2″ |

| 4/0 (Double) | *50″ | 82-1/2″ |

| 4/8 (Double) | *58″ | 82-1/2″ |

| 5/0 (Double) | *62″ | 82-1/2″ |

| 5/4 (Double) | *66″ | 82-1/2″ |

| 6/0 (Doulble) | *74″ | 82-1/2″ |

See also: Door Technical Information

Appearing regularly in Contemporary Architecture Design

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.

General Specifications

Professional Sing Core Hot Rolled Steel Wall Panels are manufactured with patented Sing Core material as the base interior substrate of the wall panel. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with your choice of EPS or urethane foam insulation, stiffeners can be added to support the performance of the door for specific end use application(s). Other foam insulation material is available in various forms depending on your specification. This default on this professional hot rolled steel wall panel is EPS foam. Natural wood 2-inch rail implants are positioned at locations as necessary for anchor points. The core material is wood framed by 1 1/4-inch natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering an exterior hot rolled steel material (skin) according to your specifications. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Professional Sing Core Hot Rolled Steel Wall Panels are manufactured with patented Sing Core material as the base interior substrate of the wall panel. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with your choice of EPS or urethane foam insulation, stiffeners can be added to support the performance of the door for specific end use application(s). Other foam insulation material is available in various forms depending on your specification. This default on this professional hot rolled steel wall panel is EPS foam. Natural wood 2-inch rail implants are positioned at locations as necessary for anchor points. The core material is wood framed by 1 1/4-inch natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering an exterior hot rolled steel material (skin) according to your specifications. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Click here for tips on How to Create the Right Sing Panel for your specific project.

This professional 10 ft. tall, 4 ft. wide, 1.5 inch thick Sing Core manufactured hot rolled steel wall panel is unfinished (unless specified otherwise) and can be guaranteed for 50 years for warp-free performance and structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the standard Sing Core wall panel is intended for use in:

Product Description: 119.5″ x 47.5″ x 1.75″ hot rolled steel wall panel manufactured by Sing Core

Wall Panel Materials: Sing Core wall panels are manufactured using Eco-friendly cold-press process. Composite materials include:

Sing Core vertical wood-grain torsion substrate filled with EPS or urethane foam and stiffeners to spec

Sing Core vertical wood-grain torsion substrate filled with EPS or urethane foam and stiffeners to specArchitectural Specifications Substitutes

For information on some of our architectural substitutes click here.

Interior Blocking: Solid wood implants can be inserted as lock blocks or anchor points. Also additional stiles (vertical wood implants) or rails (horizontal wood implants) can be positioned at any desired location inside the wall panel. (Note: Depending on your expectations, solid wood implants should be supported by at least 12 inches of Sing Core material to maintain true flatness.)

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core wall panel from factory to your location including proper crating to protect the natural beauty of your wall panel during transport.

Storage and Protection: Store your Sing Core wall panel in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that wall panel frame openings are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

Finishing: The finishing of the Sing Core professional wall panel is the responsibility of the client due to the product being delivered in unfinished quality unless specified otherwise in writing. Any sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary.

Finishing: The finishing of the Sing Core professional wall panel is the responsibility of the client due to the product being delivered in unfinished quality unless specified otherwise in writing. Any sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary.

Machining: Sing Core hot rolled steel wall panels are easy to work with in the metalwork machine shop or on-site for finishing, and metalwork modification.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Standard Sing Core wall panels feature built-in EPS insulation value of R3.5 or urethane at R6.5 rating per inch, or more, depending on architect’s specifications and the utilization of other rigid insulation material(s).

Acoustical Performance: Sing Core standard wall panels have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30*. Additional noise control specifications can be met at the behest of the customer or designer and must be noted in advance.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Warranty: Sing Core professional manufactured wall panels are structurally guaranteed and warp-free for 50 years under normal conditions.

Basic Sing Door Spec Drawings: Click here

Custom-cut Window/Lite Openings: Lite openings for glass inserts can be custom cut per your specifications (drawings above show examples of standard openings) for glass insertion.

Door Specifications |

||

Door Width |

Rough Opening Width |

Rough Opening Height 6/8 |

| 2/0 (Single) | 26″ | 82-1/2″ |

| 2/4 (Single) | 30″ | 82-1/2″ |

| 2/6 (Single) | 32″ | 82-1/2″ |

| 2/8 (Single) | 34″ | 82-1/2″ |

| 3/0 (Single) | 38″ | 82-1/2″ |

| 4/0 (Double) | *50″ | 82-1/2″ |

| 4/8 (Double) | *58″ | 82-1/2″ |

| 5/0 (Double) | *62″ | 82-1/2″ |

| 5/4 (Double) | *66″ | 82-1/2″ |

| 6/0 (Doulble) | *74″ | 82-1/2″ |

See also: Door Technical Information

Appearing regularly in Contemporary Architecture Design

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.

General Specifications

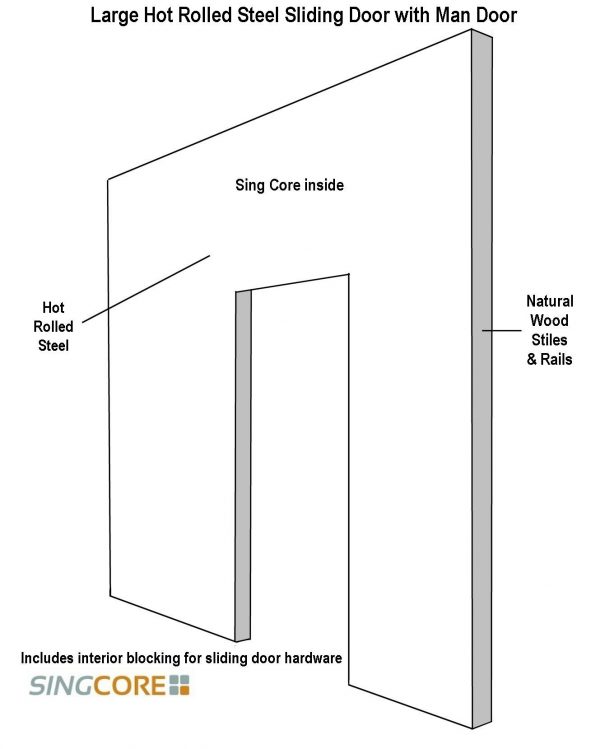

Standard Sing Core Hot Rolled Steel Sliding Door Blanks are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is recycled EPS foam. Natural wood lock blocks can be positioned at locations as necessary for locking mechanism placement and/or as sliding hardware anchor points. The core material is framed by 1.25-inch wood stiles and rails for finishing strength and attaching hardware. The torsion box is completed by adhering 20 gauge hot rolled steel as exterior material (skin) according to your specifications. The man door opening is cut out to architectural specifications.

Standard Sing Core Hot Rolled Steel Sliding Door Blanks are manufactured with patented Sing Core material as the base interior substrate of the door. The Sing Core substrate material is created using a vertical grain natural wood torsion box design while the traditionally empty voids are filled wall to wall with recycled foam. The foam material is available in various forms depending on your specification. The default is recycled EPS foam. Natural wood lock blocks can be positioned at locations as necessary for locking mechanism placement and/or as sliding hardware anchor points. The core material is framed by 1.25-inch wood stiles and rails for finishing strength and attaching hardware. The torsion box is completed by adhering 20 gauge hot rolled steel as exterior material (skin) according to your specifications. The man door opening is cut out to architectural specifications.

Hot Rolled Steel Sliding Door Surface Material

The door blank surface material is made of 20 gauge hot rolled steel unless otherwise specified. Bonding agent used in adhesion of the entire composite material is formaldehyde-free.

Click here for tips on How to Create the Right Sing Panel for your specific project.

Every Sing Core manufactured door blank is unfinished (unless specified otherwise) and professional grade is guaranteed for 50 years for warp-free and structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the standard Sing Core sliding door blank is intended for use in:

Hot Rolled Steel Sliding Door Materials: Sing Core hot rolled steel door blanks are manufactured using Eco-friendly cold-press process. Composite materials include:

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam

Sing Core vertical wood-grain torsion substrate filled with recycled EPS foamMan Door Component: The man door leaf is created to specifications to match the large hot rolled steel sliding door and is to be fitted inside the opening in the large sliding door panel. In this case, 20 g hot rolled steel with 1.25 embedded solid wood frame and lock blocks on either side of the man door.

Architectural Specifications Substitutes

For information on some of our architectural substitutes click here.

Interior Blocking: Solid wood implants can be inserted as lock blocks or anchor points. Also additional stiles (vertical wood implants) or rails (horizontal wood implants) can be positioned at any desired location inside the hot rolled steel sliding door and man door leaf. (Note: Depending on your expectations, solid wood implants should be supported by at least 12 inches of Sing Core material to maintain true flatness.)

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core large hot rolled steel sliding door with man door from factory to your location including proper crating to protect the natural beauty of your hot rolled steel doors during transport.

Storage and Protection: Store your Sing Core large hot rolled steel sliding doors in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that openings or attachment walls are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

Verify that attachment, hinging and latching assemblies operate freely and correctly

Finishing: The finishing of the Sing Core large hot rolled steel sliding doors and man doors are the responsibility of the client due to the product being delivered in unfinished condition unless specified otherwise in writing for use in interior applications only. Any exterior use must be approved in advance to avoid warranty exception and sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary. In reference to exterior applications:

Machining: Sing Core large hot rolled steel sliding doors are easy to work with in the metal shop for machining or on-site for finishing, and fastening.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Standard Sing Core sliding door blanks feature built-in insulation value with an R3 (can be upgraded to to R6.5 or more) rating per inch, depending on architect’s specifications.

Acoustical Performance: Sing Core standard sliding door blanks have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30. Additional noise control specifications can be met at the behest of the customer or designer and must be noted in advance.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean wood fiber and/or recycled material.

Warranty: Sing Core sliding door blanks come with a 10-year warranty, while professional manufactured sliding door blanks can be structurally guaranteed and warp-free for 50 years under normal conditions.

Basic Sing Door Spec Drawings: Click here

Custom-cut Window/Lite Openings: Lite openings for glass inserts can be custom cut per your specifications (drawings above show examples of standard openings) for glass insertion.

Door Specifications |

||

Door Width |

Rough Opening Width |

Rough Opening Height 6/8 |

| 2/0 (Single) | 26″ | 82-1/2″ |

| 2/4 (Single) | 30″ | 82-1/2″ |

| 2/6 (Single) | 32″ | 82-1/2″ |

| 2/8 (Single) | 34″ | 82-1/2″ |

| 3/0 (Single) | 38″ | 82-1/2″ |

| 4/0 (Double) | *50″ | 82-1/2″ |

| 4/8 (Double) | *58″ | 82-1/2″ |

| 5/0 (Double) | *62″ | 82-1/2″ |

| 5/4 (Double) | *66″ | 82-1/2″ |

| 6/0 (Doulble) | *74″ | 82-1/2″ |

See also: Door Technical Information

Appearing regularly in Contemporary Architecture Design

* Note: STC rating varies according to size, thickness, skin, and other factors. Sing Core does not rate doors, although we are fortunate enough to have one of the best sound testing labs in the world, here in the Pacific Northwest. If you require a specific STC rating, Sing Core can build a door to your architectural specifications and have the resulting door tested at our rating facility for an official rating.