A growing number of them are prioritizing technology investments, which means advisors who aren’t risking falling behind the curve in productivity and quality of service. According to a recent survey by Financial Planning, zero advisors plan to cut their technology budgets and half plan to increase their spending this year.

How Technology Is Disrupting the Insurance Industry

Technology hasn’t slowed down to wait for the outdated insurance industry to catch up. Everything from self-driving cars, big data, and sharing economy platforms have tremendous potential to disrupt the industry, and we’re seeing the growing pains manifest already.

Are High-Multiple Tech Stocks Winners or Losers?

If you like risk or if you see this as a risk-on environment, then you should consider looking into high-multiple tech stocks. They tend to perform best in risk-on environments. Investors are anticipating future growth, which increases the odds of stock appreciation. That said, it’s not that simple.

Advisors: Top Ways to Find Your First Clients and Grow

Becoming a financial advisor is a challenging endeavor with many requirements. Beyond potential education courses, you may also need to become certified as a certified financial planner (CFP) or chartered financial analyst (CFA) to set yourself apart.

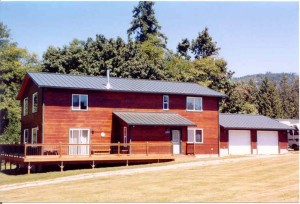

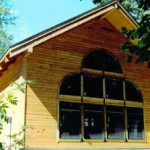

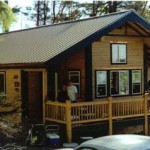

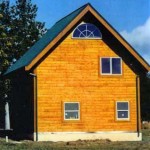

Flat Pack Homes

It is not uncommon for entire homes to be built out of flat packed Sing Core. Home owners, builders and developers can confidently build flat pack homes that will stand for hundreds of years using Sing Core for everything except for the glass and hardware.

Here are some examples of Sing Flat Pack Homes:

Wanting your home to look its best? Then why not build with the best. Click here to learn more.

Looking to build a Sing Flat Pack Home? Visit experienced builders, like:

Desk Gallery

- Portable workstations

- Non warping wood office furniture

- High precision architectural furniture

- Lightweight non warping table tops

- Lightweight Sing torsion box desk

- Non warp patented Sing desk

- large lightweight Sing office desk

- Torsion box honeycomb desk

- Sing desks and counter tops

- Lightweight, high strength, high precision Sing desk

- High strength, insulated wood desk

- Patented lightweight sing desk

- High precison non warp desk

- Patented Sing torsion box desk

- Insulated torsion box standing desk

- Non warping wood offrice tables

- Lightweight , high strenght folding table

Sing Core News at 11

Here are approximate weights for 4×8 panels for your reference

| Weights for 4×8 Panels With 1.5” Solid Edge | ||

| Skins | Thickness | Weight |

| 1/8” | 2” | 48 lbs |

| 1/4” | 2” | 65 lbs |

| 1/2” | 3” | 113 lbs |

We’re at the Las Vegas Market Show

Hello everyone,

Sing Core is currently on the 3rd floor of the C building at the World Market Center in Las Vegas. We’ll keep everyone updated on how things are going. We’ve been meeting great people and businesses who see the great potential Sing Core has.

How to build your Sing Tiny House

Step 1

Put Sing Honeycomb Panel on top of treated timber foundation frame structure

Step 2

Connect floor and wall panels together using screws and glue

Step 3

Remove honeycomb core to implant solid wood for stronger fastening

Step 4

Connect wall and roof by implanting solid wood for roof to fasten using the lightweight panel roofing and walls

Our recent Puyallup Show Pic

Here is a pic of the show we did at the Puyallup Fair in Puyallup, WA

Collapsible Dresser

New, Revolutionary Furniture Built to Last Forever: Sing furniture is the new method to build high quality furniture that can be easily knocked-down and flat-packed for easy storage, transport and/or moving. The best apartments and condos provide modular Sing Furniture for pre-furnished units for rent and/or lease. While other flat-pack furniture is available it quickly deteriorates with use and needs to be replace, while Sing furniture is built to last forever, and easily broken down and flat packed for easy storage and/or transport in between uses.

With Sing Furniture, you can go from this

to this

in 5 minutes

We put Sing panels to the test of building furniture. We found this to be the easiest way to make a collapsible dresser drawer that can be assembled and reassembled in minutes and will last forever.

Things You’ll Need:

- Sing honeycomb panels

- Screws

- hand drill

Assembling the dresser drawers is easy.

Lay panels for your collapsible drawers out flat so you have the right & left sides matching. Slide the front and back of the drawer into pre-cut slot. Add screw to each corner of drawer. No need to add glue. After sides are built screw on the bottom and your flat pack drawer is ready to be installed in dresser box.

How to Build Your SH Dresser

Your cedar modular dressers are designer quality furniture pieces that are customizable to your needs. We ship you our patented furniture panels. Choose how many drawers and the size you’d like.

Total size of finished flat pack dresser is 5’2″W x 23 1/2″ D x 34″ H

Drawers are 5 ft wide x 22” deep x 9 ½” tall.

Totally collapsible flat pack furniture for convenience of easy shipping. Each collapsible dresser can be packed in 10″h x 24″w x 60″ L box.

Things you’ll need

- Sing honeycomb panels

- Screws

- A screwdriver or hand drill

Dresser

Slides are pre-installed at factory for drawer box.

Slides are pre-installed at factory for drawer box.

Drawers

Step 1:

Order your panels from Sing Honeycomb. You can order different sizes and they are cut to order. The slides are installed at our factory.

Step 2:

Lay panels for your collapsible drawers out flat so you have the right & left sides matching. Slide the front and back of the drawer into precut slot

Step 3:

Add screw to each corner of drawer. No need to add glue. After sides are built screw on the bottom and your flat pack drawer is ready to be installed in dresser box.

Step 4:

Insert drawer into dresser. You’re done. Sing collapsible drawers are constructed with 8 screws on the ends to hold on the sides, no need for glue this is so you can assemble and disassemble for moving or easy storage

All of our products start as our basic Honeycomb core panels from there they can become almost anything you can imagine:

3″ screws to fasten each corner of wide dresser, no glue used for easy dis-assembly

Slides are pre-installed at factory

Corners of drawer are screwed together for strength

Strongest Drawer box without any glue

Collapsible dresser drawer has strength to hold 160 lbs on 5 ft span

Patented Honeycomb material is lightweight yet high strength so this collapsible dresser even though lightweight will last a lifetime.

Flat pack furniture 10″h x 24″w x 60″ L box.

- Sing Core bookshelf

- Sing Core bookshelf

- Sing Core Armoire

- Sing Core nightstand

- Sing Core nightstand

- Cutting Board

- Sing Core nightstand

- Sing Core nightstand

- Sing Core nightstand

- Sing Core bookshelf

How to Build Large Non-warp Exterior Sliding Doors

Large sliding doors are a challenge for any door manufacturer, especially if they are more than 7 ft. tall because they will warp, compromising the performance of the sliding doors and causing strain on hardware and structure due to heavy weight. That’s where Sing Core comes in.

Large sliding doors are a challenge for any door manufacturer, especially if they are more than 7 ft. tall because they will warp, compromising the performance of the sliding doors and causing strain on hardware and structure due to heavy weight. That’s where Sing Core comes in.

Our non-warp experts – and the clients that we serve – know that Professional Sing Panels are the only materials that can create a lightweight, insulated, high precision large door that can be guaranteed for 50 years for warp and structure.

Sing Core is growing in popularity across all industries as the large door solution, especially if doors are prone to warp (which most big doors are) but we also help architects, door manufacturers and high-end millworks create the best Doors of Any Size, type or style and is increasingly being sought out for endless products.

How to Build a Large Non-warp Sliding Door

The first step is to contact us with the specs for the doors that you want. The specific size(s), the exterior surface material desired and the functionality of the door, including exposure to weather conditions.

Next up, your specifications are reviewed and conferred with the trade professional via FREE Consultation.

After your free consultation, the True Flat Team will help design to design the metrics matrix of your door’s composition to result in a door that can meet or exceed your expectations and be guaranteed not to warp, bend, twist or otherwise fail (including full structural integrity) for 50 years.

At the factory, door substrate specialists bond all the materials (patented Sing Core, interior hard point blocking, Professional Sing Panels, surface materials and edging) to the design specifications.

Professional Sing Panels are extremely strong and resistant to deflection, like these non-warping door blanks that are lightweight and stronger than steel pound-for-pound.

Then skins are applied and following curing, the door blanks are shipped to door finishers who complete the door manufacturing process.

Now, your door is ready to go to the job site for installation.

The final result is an Eco-friendly lightweight, insulated, high precision large door that will not fail for 50 years, guaranteed.

These large lightweight panels with extraordinary strength can also be true flat and used for sliding doors, barn doors, carriage doors, moveable walls; if laid flat, can become table top, stage floor or mezzanine floor.

Check out the new doors for one of the world’s largest distributors of mint oil! We were really happy to build two sets of large oversize doors for an essential oil warehouse recently. One pair of panels became the double door set opens to the sides (left), while the other set of three rolls off to the same side (right).

It was important for the customer that the doors fit their doorway shape and be easy to roll. These sliding doors have a patented torsion box foam core that will keep them lightweight and smooth rolling. The series of three rolling doors link together and slide so easily that one person can push it open with just one finger.

The customer was satisfied not to need special slider tracks for our panels. Even though the doors are enormous, they don’t have the weight problems of solid core doors.

When Peter hand delivered the panels, everyone was smiling because they knew they had made the right decision in purchasing non-warping Professional Sing Panels.

Made of Any Material

Yes, thanks to Sing Core, you can have your large doors of any size made out of any flat building material, such as any available natural wood, aluminum, brass, cold rolled steel, concrete, copper, fiberglass, FRP, galvanized steel, hot rolled steel, HPL, Kevlar, LVL, metal, stainless steel, and the list goes on and on… Like these hot rolled steel doors, easily operated by hand…

Hot Rolled Steel Large Sliding Doors

- « Previous Page

- 1

- …

- 43

- 44

- 45

- 46

- 47

- …

- 95

- Next Page »