Overhead Door vs New Garage Door

If you are in the business of overhead garage door or any type of door business then this new garage door is an opportunity for you. The reward can be win-win for you and your customer.

If you are in the business of overhead garage door or any type of door business then this new garage door is an opportunity for you. The reward can be win-win for you and your customer.

The problem for overhead door and traditional carriage doors vs. Sing garage panel door

Everybody wins by switching to patented Sing Core.

The trend is 90% or more or garage doors are light duty metal or vinyl overhead doors. Traditional carriage doors cost at least 4 times more than those metal or vinyl garage doors. Now the patented Sing panel garage door with its small price tag and endless features for your customer means the end user gets a better product for less money.

| Price | Insulation | Air tight | Lightweight | Strength | Low maintenance | Security | |

| Sing Core | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Overhead Door | ✓ | x | x | x | x | x | x |

| Carriage Door | x | x | x | x | x | x | x |

The 7 Wonders of Sing Garage Panel Door are:

- Price. Sing Core panels cost about 87% less than carriage doors, yet comparable to inexpensive overhead doors in price.

- Insulation. Pre-insulated Sing garage door panels protect you from the elements and are sound-deadening.

- Air tight. Sing garage door panel maintain their seal because they are resistant to warp, bend and twisting.

- Lightweight. You don’t need expensive heavy duty hardware because they weigh one-fifth the weight of traditional carriage doors.

- Strength. Compared to other composite core materials (that range from 10-to-100 PSI) Sing garage panels weight in at 660 PSI (stronger than steel pound for pound.

- Low maintenance. Because they are lighter in weight and do not warp, bend and twist, you don’t have to worry about garage door repairs.

- Security. Your new design (if based on carriage door design) is harder to breach than simple overhead door design.

Overhead door

The overhead door is so popular due to mass production with thin gauge metal at low cost, even so we see many overhead door companies utilizing the Sing solution in their designs.

The overhead door is so popular due to mass production with thin gauge metal at low cost, even so we see many overhead door companies utilizing the Sing solution in their designs.

This is what most of American homeowners are looking for even it is easy to dent. If you use your garage as a shop or living space it has little or no insulation. Even if it is well insulated overhead, there’s virtually no way to make it air tight like carriage door. The good news is the sing carriage door is low cost and can be the new standard of garage door.

The revolutionary solution for overhead door.

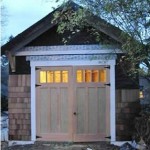

Carriage door

The carriage door is the way American home’s garages used to be made before overhead doors become popular. But due to the high price, heavy weight and not being insulated well and warping leading to air and temperature leaks – especially in the winter due to the movement of the wood (low temperatures made wood carriage doors shrink and summer heat make the doors expand).

The carriage door is the way American home’s garages used to be made before overhead doors become popular. But due to the high price, heavy weight and not being insulated well and warping leading to air and temperature leaks – especially in the winter due to the movement of the wood (low temperatures made wood carriage doors shrink and summer heat make the doors expand).

The biggest concern about carriage doors is that they are too expensive. You could spend over $4,000.00 for a 8 ft x 7 ft carriage door and over $8,000 for a 16 ft opening garage door, but none of those framed carriage doors will be easy to install due to the heavy weight and if they’re not perfectly straight. If it warps then it will leak the air and many times even otherwise adequate gaskets cannot stop the air leak.

Sing Panel Garage Door

For garage dealer or distributor:

High profit margin (selling one set of Sing carriage doors will make more money than selling 6 overhead doors, still making the customer happy, because they will have paid less than half of the traditional carriage door).

For garage door manufacturers

You will love to Sing… We will supply you the Sing Core to build better, stronger, lightweight garage doors. Sing Core is available at low price if you could order by the truck load – or even better – we might be licensing to you to build garage doors out of Sing Core.

Patented Sing Core is a true green Eco-friendly product. It is good for the earth and any creatures above and beyond.

There are many other applications for Sing Sandwich and Sing Panel.

- insulated Sing honeycomb door

- Lightweight Sing honeycomb carriage door

- Insulated Sing sandwich carriage door

- Insulated honeycomb durably door

- lightweight high strength honeycomb door

- Large insulated Sing honeycomb door

Save with Sing Carriage Doors

Welcome back the Carriage Door that is insulated, sound deadening, lightweight and stronger than steel pound for pound.

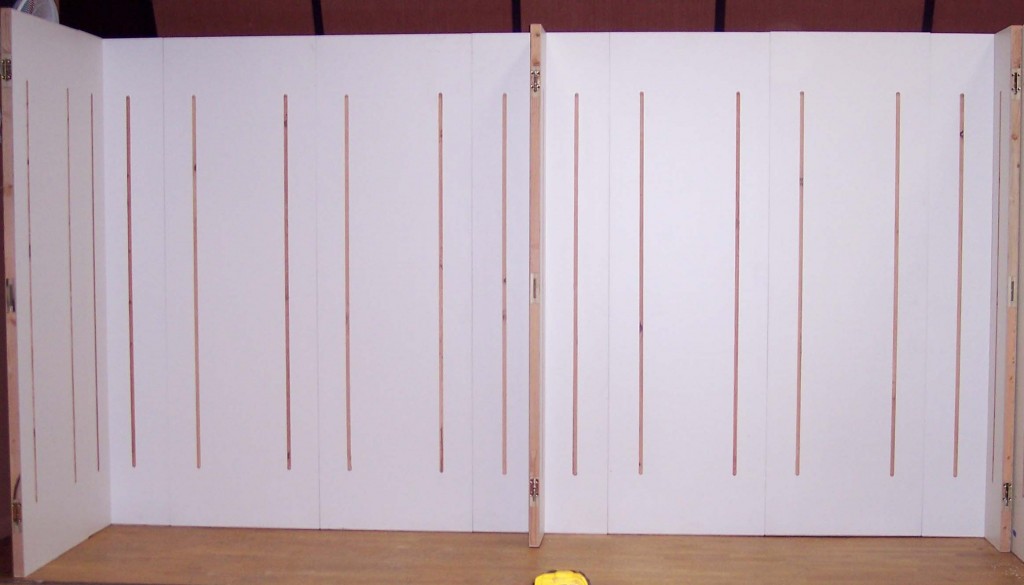

These bi-fold carriage doors were made of patented Sing Core.

If you in the business of overhead garage doors or any type of door business then this is an opportunity for you. The reward can be win-win for you and your customers.

Challenges for overhead doors and traditional carriage doors

OVERHEAD DOOR

The overhead door is so popular due to the mass production with thin gauge metal at low cost. Let’s face it; most of American homeowners are looking to save money, even if it is easy to dent.

If you use your garage as a shop or expanded living space the overhead door has little or no insulation. Even it is well insulated overhead, there’s no way to make it air-tight, like a carriage door. Still, due to the low cost, it ha1s become the standard for garage doors.

CARRIAGE DOOR

The classic carriage door is the way American home garage doors were made before the overhead door became so popular.

Carriage doors had their challenges, like being very heavy adding stress and strain to the hardware and structure, no insulation, and warping due to weather change compromising an otherwise perfect seal.

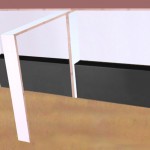

USING SING CORE

Using Sing Core as the basis of your carriage door – or any garage door solution – will provide an Eco-friendly lightweight high-strength structure that is insulated, warp and rot resistant.

All you need to do is to add the desired molding, trim, finish and hardware to imbue them with any appearance you desire. See: Sing Core Doors

The results are nothing less than spectacular and the Sing solution is quickly becoming the preferred manufacturing method for the most high-end door jobs around the world.

Patented Sing Core can be used in endless applications.

Modular Trade Show Displays

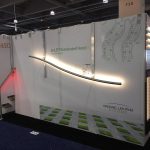

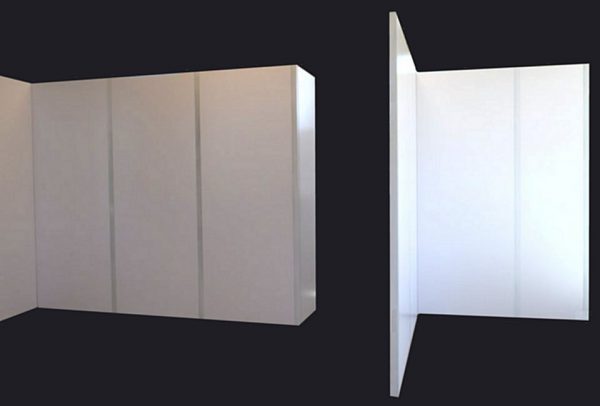

Sing Core is proud to announce the first modular trade show display system that is lightweight, high-strength and Eco-friendly for a better world.

Trade Show Display Components

This unique material allows you to build a trade show display without requiring a 2×4 frame and is many times stronger. Even though your trade show wall will be 2 inches thick it will have the strength of a fully framed wall because the structural frame is built into each lightweight high-strength trade show panel.

Build Your Own Custom Trade Show Booth

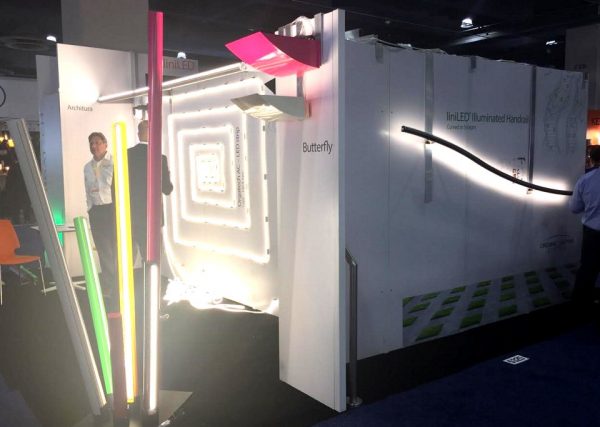

Take a look at this custom trade show booth that was designed and built by the company using our modular trade show components.

How to create your own trade show booth design system is easier than learning your ABC‘s. So, come on and do the Sing creation with me.

A. Decide what you want and the components you need

- A: Create Your Design

- B: Create Shopping List

- C: Experience the Results

B. We give you everything you need to create your custom trade show booth

C. You are proud to have the best trade show display

|

|

|

|

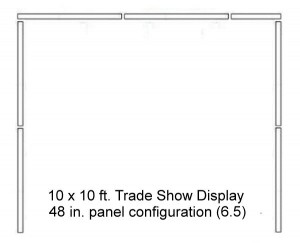

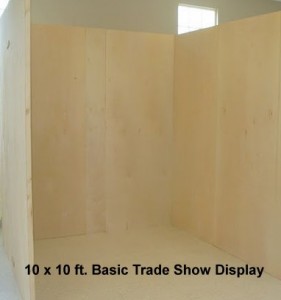

10 ft. x 10 ft. Trade Show Display Example |

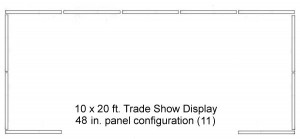

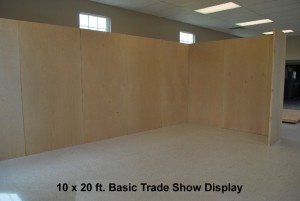

10 ft. x 20 ft. Trade Show Display Example |

|

|

Each Sing Sandwich panel can be used as many different trade show components and in a variety of trade show applications, like

| 1. track wall 2. slatwall 3. movable wall 4. partition wall 5. two story trade show booth 6. trade show floor 7. trade show roof 8. floating shelves 9. museum cable hanging shelves |

For high end custom trade show displays, Click Here.

Options include adding exterior surface materials, like any wood species, aluminum, concrete, fiberglass/FRP, galvanized steel, HPL, metal, plastic, stainless steel, etc…

Now available in affordable lightweight slatwall trade show display.

We Welcome Custom Trade Show Ideas

How to Make Your Own Design

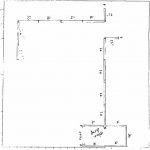

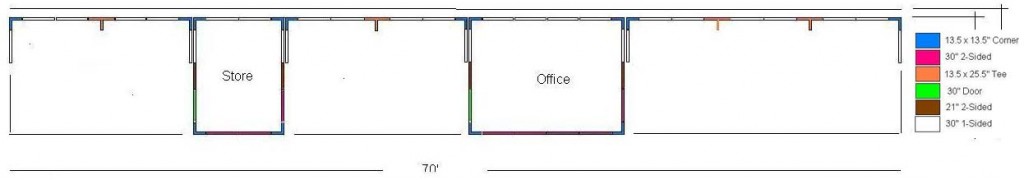

Now that you know the components, you can easily design your own custom trade show booth… For instance, you could provide us with a drawing, like this:

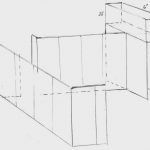

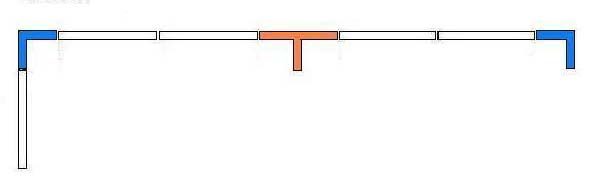

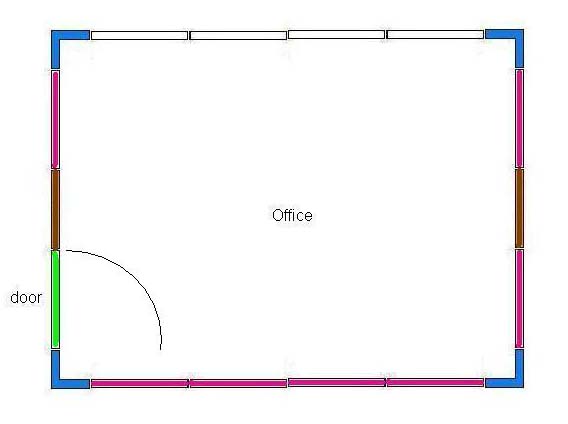

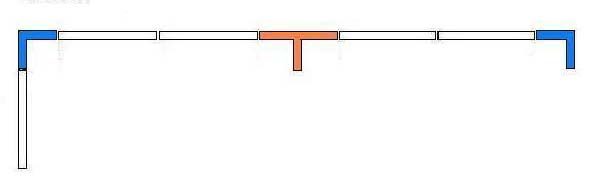

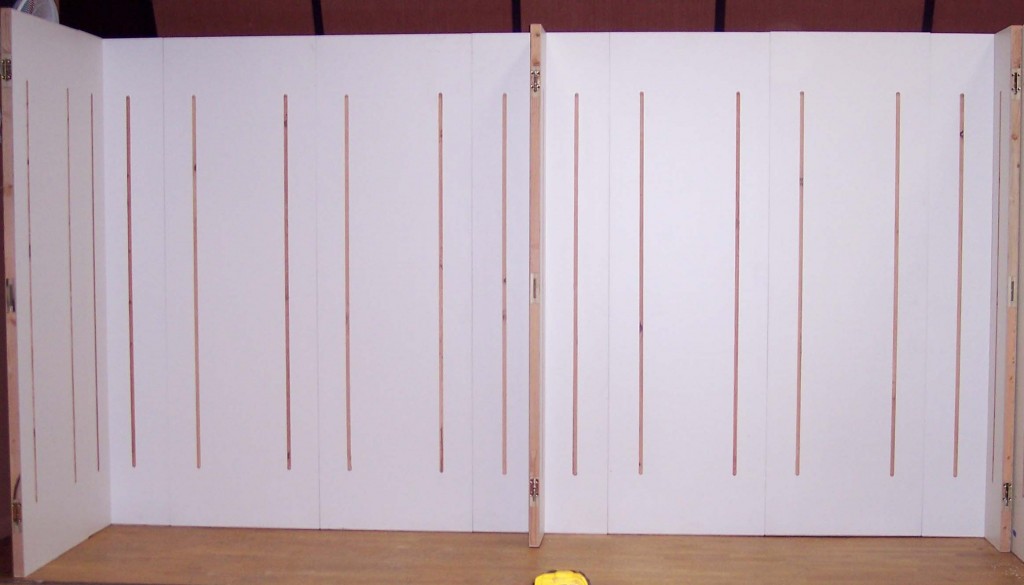

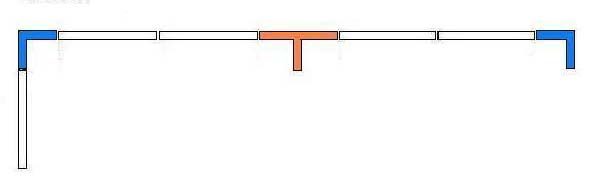

In the drawing (above) this 15 foot wide trade show booth has a left wall depth of 4 foot for display purposes. The white panels represent Sing Trade Show Panel “A,” the blue represents the Sing Trade Show Display “L” and the salmon colored Sing Trade Show “T” is in the middle. In this example, the client requested vertical grooves be pre-cut for installation of track for trade show display hardware. Sing trade show displays can be configured to your specifications. The order would reflect 5 Panel As, 2 Display Ls and 1 Display T. Here are the results:  Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:

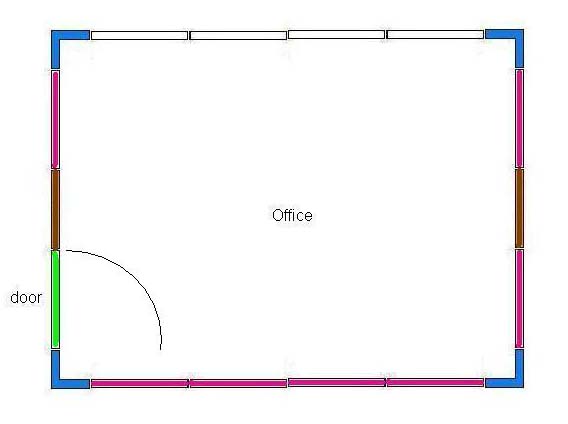

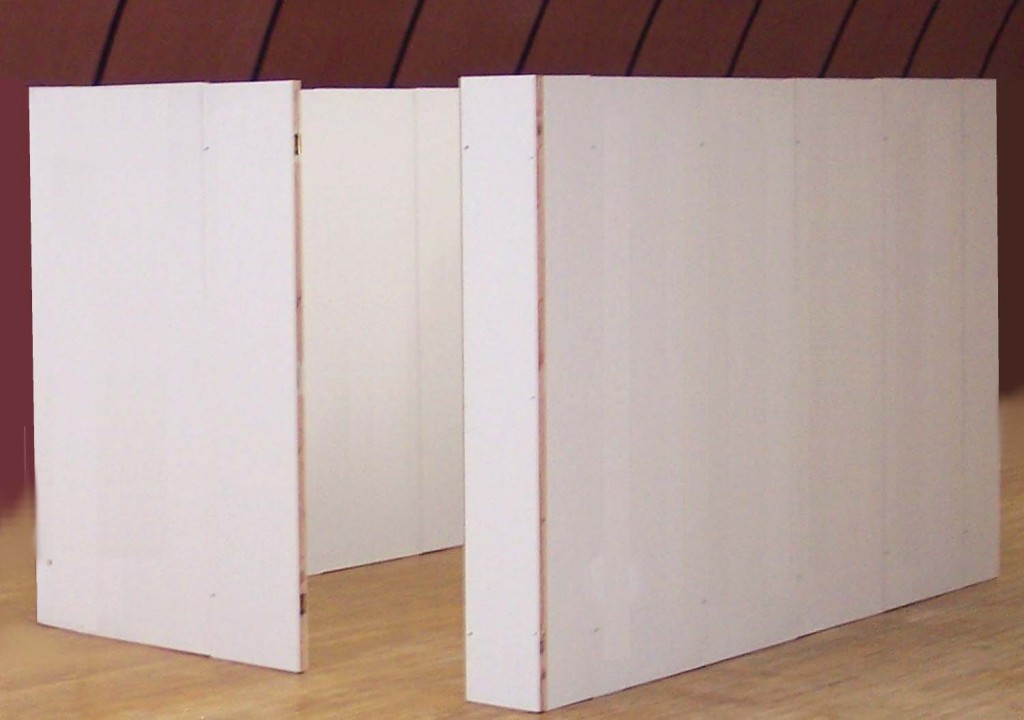

Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:  The order for this office space included 7 custom (C) 30 inch magnetic whiteboard panels. This order would reflect 4 Panel As, 2 Panel Bs, 7 Panel Cs, 1 Panel D and 4 Display Ls. The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:

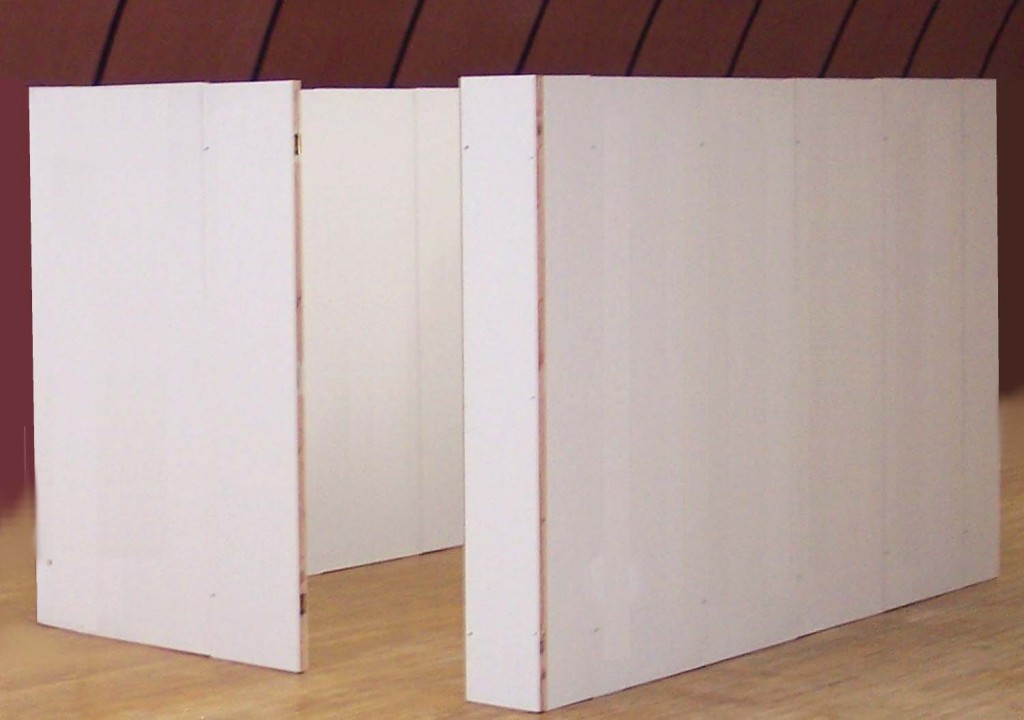

The order for this office space included 7 custom (C) 30 inch magnetic whiteboard panels. This order would reflect 4 Panel As, 2 Panel Bs, 7 Panel Cs, 1 Panel D and 4 Display Ls. The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:  Note: Prices are subject to change due to material cost and prices do not include shipping. Final price (especially in case of customized specifications) is not final until agreed to and authorized by purchaser and Sing Core. For accurate wholesale pricing, industry trade professionals are encouraged to inquire directly by contacting us direct.

Note: Prices are subject to change due to material cost and prices do not include shipping. Final price (especially in case of customized specifications) is not final until agreed to and authorized by purchaser and Sing Core. For accurate wholesale pricing, industry trade professionals are encouraged to inquire directly by contacting us direct.

For our more discriminating clients who prefer our premium trade show display components:

To see your ideal trade show displays come to life, simply design your display using our lightweight, high strength trade show components as listed below.

To see your ideal trade show displays come to life, simply design your display using our lightweight, high strength trade show components as listed below.

Once you have decided on how many panels, in what sizes and how many Ls and Ts will be in your system it is quick and easy to order online by clicking the buttons for the products that you need.

After you’ve received your Sing Trade Show Displays you will discover that assembly of your trade show displays is as quick easy as ordering.

Get the upscale trade show display wall panel components that you want:

Sing Trade Show Panel “A”

![]() They key component for designing and building your trade show display walls is our “A” trade show panels. These patented display panels measure 36 inches wide. They are lightweight and easy to handle and come complete with Frost White MDF exterior finish. 36 lbs. Panel “A”

They key component for designing and building your trade show display walls is our “A” trade show panels. These patented display panels measure 36 inches wide. They are lightweight and easy to handle and come complete with Frost White MDF exterior finish. 36 lbs. Panel “A”

Sing Trade Show Panel “B”

![]() Our alternatively-sized component for your custom trade show display walls consists of our “B” trade show panels. These patented display panels measure 22 inches wide. 25 lbs. Panel “B”

Our alternatively-sized component for your custom trade show display walls consists of our “B” trade show panels. These patented display panels measure 22 inches wide. 25 lbs. Panel “B”

Sing Trade Show Display “L”

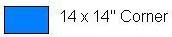

![]() The Sing tradeshow display L is the key corner component. The standard dimensions of this corner connector is 14 inches by 14 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining. 37 lbs. Display “L”

The Sing tradeshow display L is the key corner component. The standard dimensions of this corner connector is 14 inches by 14 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining. 37 lbs. Display “L”

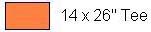

Sing Trade Show Display “T”

![]() The Sing trade show display T is the component that joins two trade show wall panels together. As you determine your design keep in mind the dimensions as it measures 28 inches wide by 14 inches deep. The patented Sing T can be used as a wall footing to add stability over long spans or to add a perpendicular wall or add other components. 53 lbs. Display “T”

The Sing trade show display T is the component that joins two trade show wall panels together. As you determine your design keep in mind the dimensions as it measures 28 inches wide by 14 inches deep. The patented Sing T can be used as a wall footing to add stability over long spans or to add a perpendicular wall or add other components. 53 lbs. Display “T”

How to Build a Wall for Trade Show Displays and Buy It Now

To see your ideal trade show displays come to life, simply design your display using our lightweight, high strength trade show components as listed below.

To see your ideal trade show displays come to life, simply design your display using our lightweight, high strength trade show components as listed below.

Once you have decided on how many panels, in what sizes and how many Ls and Ts will be in your system it is quick and easy to order online by clicking the buttons for the products that you need.

Pre-packaged Trade Show Display Kits, with or without lighting systems, are in stock and available with FREE SHIPPING. Allow up to 1 week for delivery by freight.

After you’ve received your Sing Trade Show Displays you will discover that assembly of your trade show displays is as quick easy as ordering.

Plus we have, “Try before you buy,” leasing program and economy discount options for our clients looking for the best price (contact us for prices and availability).

How to Get Sing Core to Build Your Best Trade Show Display

- Know what you want

- Have at least an idea or drawing of what you want your trade show display to look like

- Determine how many and what size of panels you will need for your trade show booth project

- Know what exterior material you want on your trade show panels

- Decide how you will manufacture your project

- Seek out a professional

- Architect, Designer, Design/Build, General Contractor, Mill Work, etc…

- Give them your drawing, specifying Sing Core inside

- They will deal directly with us

- Do it Yourself (DIY)

- Fill out your advanced order form

- Your trade show panels arrive at your location

- You will do the finish-work

- You have good woodworking skills to complete your trade show panel finish and installation

- You can obtain the trade show hardware you need

- Congratulations!

- You are the proud owner of the most advanced trade show display in the world that is

- Eco-friendly

- Lightweight

- High-strength

- Insulated

- High-performance (non-warping true flat doors, walls, furniture, etc…)

- Will last longer than anything made with any other material with these benefits

Example

How to Make Your Own Design

Now that you know the components, you can easily design your own custom trade show booth… For instance, you could provide us with a drawing, like this:  In the drawing (above) this 15 foot wide trade show booth has a left wall depth of 4 foot for display purposes. The white panels represent Sing Trade Show Panel “A,” the blue represents the Sing Trade Show Display “L” and the salmon colored Sing Trade Show “T” is in the middle. In this example, the client requested vertical grooves be pre-cut for installation of track for trade show display hardware. Sing trade show displays can be configured to your specifications. The order would reflect 5 Panel As, 2 Display Ls and 1 Display T. Approximate retail price: $4,342.00 Here are the results:

In the drawing (above) this 15 foot wide trade show booth has a left wall depth of 4 foot for display purposes. The white panels represent Sing Trade Show Panel “A,” the blue represents the Sing Trade Show Display “L” and the salmon colored Sing Trade Show “T” is in the middle. In this example, the client requested vertical grooves be pre-cut for installation of track for trade show display hardware. Sing trade show displays can be configured to your specifications. The order would reflect 5 Panel As, 2 Display Ls and 1 Display T. Approximate retail price: $4,342.00 Here are the results:  Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:

Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:  The order for this office space included 7 custom (C) 30 inch magnetic whiteboard panels. This order would reflect 4 Panel As, 2 Panel Bs, 7 Panel Cs, 1 Panel D and 4 Display Ls. The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:

The order for this office space included 7 custom (C) 30 inch magnetic whiteboard panels. This order would reflect 4 Panel As, 2 Panel Bs, 7 Panel Cs, 1 Panel D and 4 Display Ls. The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:  Note: Prices are subject to change due to material cost and prices do not include shipping. Final price (especially in case of customized specifications) is not final until agreed to and authorized by purchaser and Sing Core. For accurate wholesale pricing, industry trade professionals are encouraged to inquire directly by contacting us direct.

Note: Prices are subject to change due to material cost and prices do not include shipping. Final price (especially in case of customized specifications) is not final until agreed to and authorized by purchaser and Sing Core. For accurate wholesale pricing, industry trade professionals are encouraged to inquire directly by contacting us direct.

Click Here to Price Your Custom Trade Show Display

New Revolution in Trade Show Display Material

These new, lightweight, high-strength and true flat patented panels are sold by the square foot, just like traditional plywood and sheet goods.

Click Here for Economy Trade Show Panels

40 ft engineered plywood: 2 inch thick weighs in at only 2 lbs. per sq. ft.

Metal panel: 20 ft. in length x 5 ft. wide x 1 inch thick weighing in at 3.75 lbs per sq. ft. and strong enough to hold 2 people. See pix.

Watch the video for slatwall, track wall, magnetic wall, two story trade show office, floating shelf, cable hanging shelf, etc… You design and we will build the panels for you – this 70 ft. custom trade show system be assembled in less than an hour by 1 man; including 70 ft. of back wall, side walls an enclosed office and storage area.

Now available in affordable lightweight slatwall trade show displays

All Sing Panels are sold like plywood by per square foot.

Fast price quote within 24 hours for custom trade show displays made to your specifications.

Your choice of material options including (but not limited to) HPL, plastic, any type of metal, plastic, plywood, etc… in many colors ready to trim to almost any size and/or add vinyl or metal skin for magnetic sign or hook. Available in almost any size thickness and/or shape.

High performance engineered plywood

High performance engineered plywood

See pictures of Sing Panel and Sing Post and Beam supplied to high-end mill works from coast to coast. Click here to see clients list.

How is it possible?

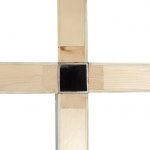

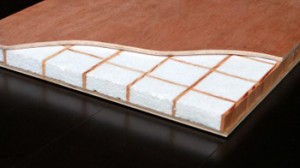

The secret is in our patented natural vertical-wood-grain-torsion-box-filled-with-foam core that allows your team to build huge displays (even 2 stories) without framing.

Wholesale to trade show manufacturers

Click here to see our retail price and compare how much per sq. ft. your cost for the untrimmed patented Sing Panel. You will find out Sing Panel will not only become your top performer in the trade show display industry but reward you with a good profit margin by using Sing Panels.

All Eco-friendly Sing Panels, post and beams are proudly made in the USA.

We can produce hundreds of panels per day by our state of the art technology.

For your viewing please we are providing your with some extra photographic representations of some of the many possibilities of teaming your trade show display company with Sing Core. Feel free to view our Trade Show Display Gallery.

- Insulated office floor panels

- Sing T in wall assembly

- Lightweight + Strong

- 4-way Connection

- X Connector

Custom Trade Show Displays

Due to the unique characteristics of patented Sing trade show display components (lightweight, high-strength and true flat), it has never been easier for you to design your own custom trade show displays. What’s more is that all of the components can easily be flat-packed for convenient packaging, shipping and storage.

We can even provide custom trade show display carts for packaging and shipping your trade show booth components.

How to Sing Your Trade Show Booth Design

Once you understand the individual components of the Sing trade show display system, it is easy to configure your own custom trade show displays.

All Sing trade show display components lock in easily with our built-in simple cam lock system. See: High Performance Trade Show Case Study

Sing Trade Show Booths are designed to last forever. Unlike other displays that are rented – or disposable – our trade show displays are designed to last and be used over and over again.

Sing Trade Show Display Components

Sing Trade Show Display “L”

Sing Trade Show Display “L”

The Sing tradeshow display L is the key corner component.

The standard dimensions of this corner connector is 14 inches by 14 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments.

All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining.

Sing Trade Show Display “T”

Sing Trade Show Display “T”

The Sing trade show display T is the component that joins two trade show wall panels together.

As you determine your design keep in mind the dimensions as it measures 28 inches wide by 14 inches deep.

The patented Sing T can be used as a wall footing to add stability over long spans or to add a perpendicular wall or add other components.

- Back view of Sing T

- Adding footing to Sing T

- Sing T in wall assembly

Sing Trade Show Panel “A”

They key component for designing and building your trade show display walls is our “A” trade show panels. These patented display panels measure 30 inches wide. They are lightweight and easy to handle.

They key component for designing and building your trade show display walls is our “A” trade show panels. These patented display panels measure 30 inches wide. They are lightweight and easy to handle.

Sing Trade Show Panel “B”

Our alternatively-sized component for your custom trade show display walls consists of our “B” trade show panels. These patented display panels measure 22 inches wide.

Custom sized components can easily be created to match your individually unique custom trade show displays. Simply provide us with your drawings and measurements and we will make your custom trade show booth dreams come true.

How to Make Your Own Design

Now that you know the components, you can easily design your own custom trade show booth…

For instance, you could provide us with a drawing, like this:

In the drawing (above) this 15 foot wide trade show booth has a left wall depth of 4 foot for display purposes. The white panels represent Sing Trade Show Panel “A,” the blue represents the Sing Trade Show Display “L” and the salmon colored Sing Trade Show “T” is in the middle. In this example, the client requested vertical grooves be pre-cut for installation of track for trade show display hardware. Sing trade show displays can be configured to your specifications.

In the drawing (above) this 15 foot wide trade show booth has a left wall depth of 4 foot for display purposes. The white panels represent Sing Trade Show Panel “A,” the blue represents the Sing Trade Show Display “L” and the salmon colored Sing Trade Show “T” is in the middle. In this example, the client requested vertical grooves be pre-cut for installation of track for trade show display hardware. Sing trade show displays can be configured to your specifications.

Here are the results:

Another example is this drawing for an implant modular office for use in a trade show display based on the customer’s drawing:

The resulting office space as follows was assembled in minutes with our lightweight, high strength, modular cam lock design:

Versatile

Standard exterior surface material is white HPL (high pressure laminate) or Formica. This is a durable surface that is easy to clean and is an excellent surface for applying self-adhesive vinyl graphics or coverings to further customize your custom trade show displays.

You will never out-grow your patented Sing trade show display system because it grows with you.

It doesn’t get any better than the best.

- 4-way Connection

- Lightweight + Strong

- X Connector

- Cam lock wall assembly

High Performance Trade Show Displays

If you’ve been going to trade show events for some time, you know – even though you have learned how to accommodate and settle for existing trade show booth displays – you’ve dreamed of having a better trade show exhibit display system.

If you’ve been going to trade show events for some time, you know – even though you have learned how to accommodate and settle for existing trade show booth displays – you’ve dreamed of having a better trade show exhibit display system.

Realize your perfect trade show booth design

We have been honored to help some of the most discriminating clientele – who only want the best representation of their company, product or service – see their trade show booth ideas come to life.

Here’s a true story:

Recently we were contacted by a high-end consumer designer who has been going to trade shows for 30 years. Facing the limitations of the trade show industries offerings (even the most high-end solutions) left him wanting more. Over the last 30 years, he had developed what he believed was the best trade show system ever conceived.

This designer presented Sing Core’s inventor with some simple drawings of his dream trade show display. Between the two of them, three weeks later the designer’s dream did come true thanks to patented Sing technology that made it all possible.

Isn’t it time you made your trade show dream come true? Contact us and make it happen.

Imagine being able to custom design your own tradeshow display system that would be:

- High tech

- Lightweight

- High-strength

- Insulated

- Guaranteed

Back to our story:

In three weeks, after the designer began to work with the inventor of Sing Core, the ultimate trade show system had come to life. Custom crates on wheels were manufactured to the designer’s specification to house all the flat packed trade show display wall panels. The first time the 70 foot long display was assembled by one person who had never connected two panels previously. This one man completely assembled the entire system in less than an hour by himself.

High tech

Sing trade show panels are the newest revelation in trade show panel design that uses patented natural wood torsion box filled with solid foam insulation wall-to-wall as the interior substrate of the moveable trade show walls. This Eco-friendly technology is used all over this planet – from beneath the sea to outer space.

Sing trade show panels are the newest revelation in trade show panel design that uses patented natural wood torsion box filled with solid foam insulation wall-to-wall as the interior substrate of the moveable trade show walls. This Eco-friendly technology is used all over this planet – from beneath the sea to outer space.

Lightweight

Sing trade show wall panels are a fraction of the weight of other wall panels, weighing in at one-third the weight or less.

High-strength

No other affordable trade show booth panel can compare to Sing trade who wall panels in terms of shear strength that has been independently tested at the University of Washington to be over 600 PSI.

Insulated

You can offer your visitors the added comfort and convenience of having fully insulated walls naturally imbued with sound deadening characteristics.

Guaranteed

Only museum quality Sing trade show wall panels can fully guaranteed to remain structurally sound and not to warp, bend, twist, cup or crack for 10 years.

Bring us your trade show display ideas

By working with us, you can design your own custom trade show displays into any configuration to have the most incredible trade show exhibit modular displays.

Imagine designing a system that could be fully packed flat and shipped for pennies on the dollar. Wall panels can be easily transported and assembled by one person.

In fact, this 70 foot trade show display (that includes fully enclosed storage and office areas) was assembled by one person in less than one hour (see photo above).

This 70 feet of museum quality custom display includes:

- 14.5 x 10 foot trade show booth

- 7 x 10 foot trade show store room

- 14.5 x 10 foot trade show booth

- 12 x 10 foot office space (enclosed)

- 22 x 10 foot trade show booth

… and all of this could be easily flat packed into a crate on wheels for easy transport.

There is no limit to your trade show booth design ideas being realized for your upcoming trade show exhibits.

Think about it; no more heavy walls, expensive transportation and construction expenses. Every wall locks firmly into place with our cam lock wall panel design by one person with less risk of on-site injury. Plus, your system can easily be modified and upgraded to your needs – not replaced – for 10 years.

If you’re using tradeshow displays and you want to take away the pain associated with traditional trade show booths, you owe it to yourself, your company and your desire to build a better world to contact Sing Core.

Achieve the high performance trade show display results that you can be proud of in your exhibit design for the perfect expo display.

- 4-way Connection

- Lightweight + Strong

- X Connector

- Cam lock wall assembly

What Can be Made from Sing Sandwich Panels?

What will you make from patented Sing Sandwich panels?

Affordable Eco-friendly insulated torsion box reinforced honeycomb panels help you to build the best lightweight high strength products.

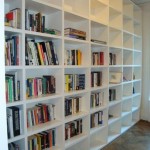

- Sing Core bookshelf

- Sing Core bookshelf

- Insulated Storage Unit

- Panelized Tiny House

- « Previous Page

- 1

- …

- 55

- 56

- 57

- 58

- 59

- …

- 95

- Next Page »