Door News

No More Warped Door

50 Year True Flat Replacement Doors Copper Door Building the most stable door is our specialty. With our patented true flat technology, Sing Core provides clients with insulated Eco-friendly lightweight high-strength doors that prevent wood warping doors – See more…

Make Your Own High Tech Door Core

Guaranteed: Less labor, less material cost to build the best lightweight, high-strength (any type of) door using patented Sing Core technology and you can be licensed to manufacture it yourself. Inventor Peter Sing would like to talk to your owner/CEO about partnering See more…

Join Leading Edge High-end Door Makers

You might be able to relate to this story about the most sophisticated high-end door company in history with the longest track record become one of our newest Sing Clients. Recently we were contacted by one of the most reputable door manufacturers in the United States inquiring – See more…

Architectural Specification Substitutes

Due to being the newly invented and possibly the most significant improvement in building materials in the last century, it is not uncommon to see Sing products recommended as substitutes for products in the original specifications initially specified by architects. Even though – See more…

Weatherproof Water Tight Wood Door

For exterior applications Sing Core wood doors are not only built true flat and designed to stay flat for centuries but they can also be virtually impervious to extreme weather conditions remaining watertight and will not warp, bend or twist over time thanks to our patented – See more…

New Door Tech vs. Old Door Tech

There is a new concept in Eco-friendly door manufacturing that raises the question: “Is Sing Door Core a better way to build doors than any other type of door?” Sing Core’s patented door core has the unique ability to build a true flat, weather proof/water tight, lightweight door – See more…

Custom Door Window Glass Openings

Custom window cut-outs – any size – any shape – for door professionals and manufacturers. Introducing the new, “American,” French door. Say, “Au revoir,” to the traditional French door that limits your design options, and say, “Hello,” to the new Americanized Sing door that is nearly – See more…

What is True Flat?

The challenge for high end door makers – especially wood-based large doors – is true flat. Even the best millworks in the world are looking for solutions primary concerns are raised when an oversized large door is made of a beautiful exotic wood. A door like this can cost tens of – See more…

True Raised Panel Door

A new door fabrication technology is changing hundreds of year door making tradition. Now high quality precision (Sing Core tolerance within .0006 inch) doors can be proudly manufactured quickly and easily in the USA. Patented Sing Core can be used in many applications, to – See more…

True Flat Sliding Doors

True flat technology is based on expertise in building a sliding door that can be guaranteed true flat and stay flat. This composite science includes the proper proportions of Sing Core, aluminum and/or other materials and bonding agents based on your requirements or – See more…

Big Aluminum Door

Patented Sing Core’s unique attributes enables us to make the biggest doors that are lightweight, extremely strong and Eco-friendly. Sing Core produces the only affordable solution to building a big door that can be guaranteed true flat… and will stay flat for lifetimes. Sing Core…

Greater Sliding Doors

One of the greatest attributes of your sliding door is the actual sliding performance of the sliding door, especially closet doors. Certainly, upon installation, your wood sliding door or interior pocket doors may perform superbly… but for how long? It may be important for you to – See more…

Big Sliding and Oversized Doors The Most Popular Sing Applications

Sing products have hundreds of application but sliding doors and oversize doors are the most popular. Why does Sing Core make more oversize sliding and big doors than anything else? Because only Sing Doors are true flat, It’s a challenge for people in the building industry – See more…

Modern Sliding Barn Door

Sing Modern Sliding Barn Door 101 Introductory Special Most Sing sliding doors are sold to the most expensive homes in USA and abroad, but this is not the inventor Peter Sing’s goal. This special door is designed to introduce Sing products to the world in an effort to reach every See more…

More People Switching from Overhead Garage Doors to Carriage Doors

We are celebrating the wave of people who are making the change from standard overhead garage doors to the more elegant, energy efficient, lightweight, high-strength and Eco-friendly Sing Carriage Doors. We also appreciate the garage door industry, especially the overhead garage – See more…

Sound Proof Doors

All Sing Core Doors are pre-insulated with sound dampening features that are enjoyed by all suppliers and end-users. This high-level of performance has increased the demand for a solution for our discriminating high-end clients to raise the bar once again. You will find Sing Sound Doors – See more…

The Best Door

It is a very particular sort of individual who searches for the best door. This is not your average door buyer, who is looking for a door to simply block a view, or to achieve some sense of privacy. No, these discerning clients, designers, architects and homeowners seek attributes far – See more…

$58 Door vs $580 Door Comparison

Compare our $58 Paint Grade Sing Core Door to their $580 Door When you’re in search of the best door possible it is important to compare Sing Core doors to expensive alternatives. We say, Heavy does not mean strong Lightweight does not mean weak Most expensive does not mean – See more…

Flush Wood Doors

Add simple beauty and elegant appearance of a solid wood flush door to your home without having to sacrifice the qualities of a highly-engineered architectural wood flush door. Sing Core flush wood doors feature natural and composite construction materials that embrace true – See more…

Sliding Barn Door

Sing Core interior barn doors are a bold fashion statement used by architects and designers that add elegance and beauty to nearly any environment with increased functionality due to the attributes of being lightweight, stronger than steel and Eco-friendly. With Sing Core sliding – See more…

Sliding Door

Sing Core is the new way to design your door Solid like a rock, light like feather so you don’t smash your finger. Wood sliding patio doors, sliding glass doors, and even the most high-fashion vinyl sliding patio door can be expertly engineered with patented Sing Core technology – See more…

New Record for True Flat

True : having all the expected or necessary qualities of a specified type of person or thing. Flat : being or characterized by a horizontal line or tracing without peaks or depressions. Architectural standard for true flat: ¼ inch deflection for an 8 foot span. True flat technology – See more…

Door Representatives

As a door professional or specialist you are familiar with how conventional doors are made and promoted. Get ready for something new: Introducing a new technology in door core and manufacturing that is making a huge impact in the extremely high-end door market. If you Google – See more…

New Doormaking Technology

If you Google Image Search honeycomb core door, lightweight core door or sing core door, you will see who the players are in this new generation of door manufacturing technology. Sing Core is Available for All Door Manufacturers Newly patented Sing Core has contacted over 100 – See more…

Lightweight High Strength Eco Friendly Metal Pivot Doors

When professionals seek out extraordinary, unique and/or oversized modern steel doors the most conscientious purveyors settle on a Sing Core metal pivot door. While exquisitely masterful in their design, modern metal pivot doors present many challenges. The first challenge to – See more…

Best Door in Manhattan

Manhattan Penthouse brings Sing Core Door to new heights. No place is too far. This custom made trapezoid door traveled over 2,921 miles from coast to coast, now on final leg of its journey to its new home in upscale Manhattan apartment. We specialize in custom sizes, shapes – See more…

Large Oversize Sliding Door Testimonial

Check out the new doors for one of the world’s largest distributors of mint oil! We were really happy to build two sets of large oversize doors for an essential oil warehouse recently. One pair of panels became the double door set opens to the sides (left), while the other set of three rolls – See more…

Garage Doors

Peter was inspired recently to find yet another use for Sing Honeycomb Panels. We’re launching a line of insulated panels for overhead garage doors. He noticed that too many nice homes have dinged up garage doors. It’s because garage doors are expensive to repair. You don’t want – See more…

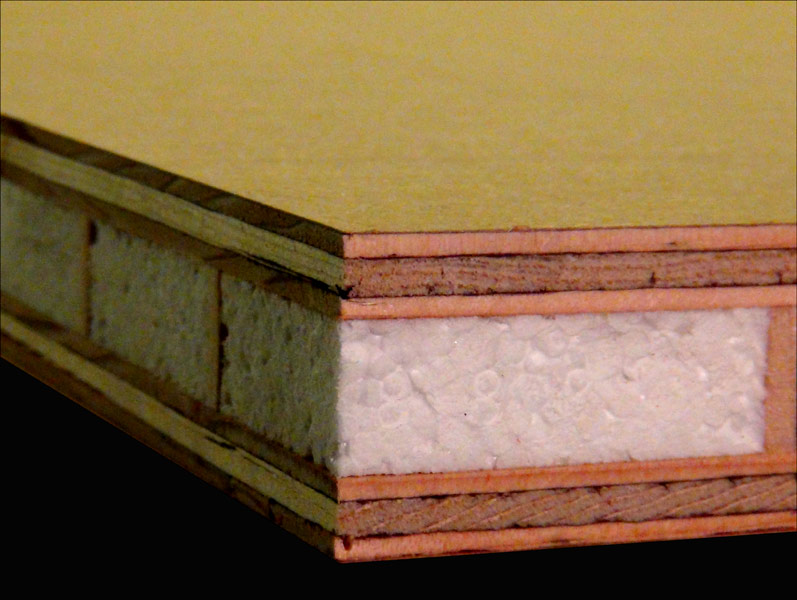

Foam Core Alternative

Sing Core melds the best of two worlds, the lightweight scientific development and the best of nature’s natural resources into Eco-friendly high-tech, space-age advanced composites.

Foam core panels have served the building and construction community well, helping address the issues of weight in large projects. Used as […]

Balsa Wood Alternative

Sing Core is the new space age composite material that is the affordable cousin to Balsa wood and has many features that Balsa wood does not have. Using the best combination of science and nature, patented Sing Core is a Balsa wood hybrid, using a natural vertical wood torsion box design.

While torsion box has […]