Aluminum Honeycomb Panel

When looking for the best aluminum material one can become confused at all the different options that there are in the variety of building materials that are available.

Now only $256 for a 4’x8′ sheet.

| Size | Sqft | Price |

|---|---|---|

| 4’x8′ | 32sqft | $256/sheet |

| 4’x10′ | 40sqft | $320/sheet |

| over 4’x10′ | any size | Ask for price |

Custom Sizes Available

If you have a special custom, architecturally specified, or otherwise unique requirement for your project, don’t hesitate to ask. We are experts in the unexpected, and seek to exceed your every desire. Visit our pricing page for more information and to submit your price quote request.

First, you must establish what your goals are for your project. You must determine the answers to questions, like…

- Can I use composite panels?

- Will my project require structural strength?

- Will it need to be dent resistant?

- Require weather resistant or waterproof?

- Does my project need to have sustainable or eco-friendly impact?

- Must the surface material be appealing to the eye?

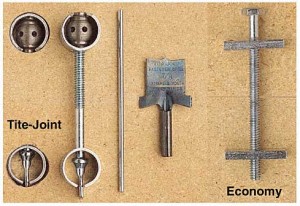

- Will I be using hardware? If so, heavy duty or lightweight?

- How many aluminum honeycomb panels will I need?

- What would be the optimal size of my panels?

- What is the price of the aluminum honeycomb panel?

- What is the shipping cost of the panels?

Just to name a few.

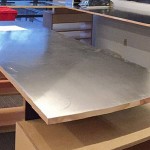

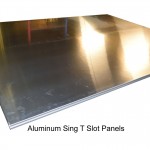

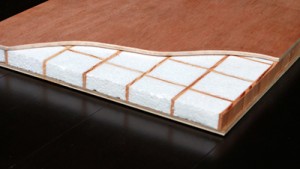

Aluminum face sheets over patented sing core. Sing core aluminum panels are lightweight, dent resistant and stronger than steel in inch-per-inch independent tests. Sing core aluminum panels are used where impact is likely to occur.

Our sing core aluminum composite panels are the solution for a wide range of applications requiring guaranteed flat, light weight, and rigid specifications.

Patented Sing Core aluminum composite panels are stronger than steel pound-for-pound, utilizing a 2×2 inch grid with our patented design and process ensures more strength in comparison to aluminum core.

Other advantages of the patented Sing Core aluminum composite panel includes sound deadening, built in insulation, features a stronger core and is eco-friendly.

Advantange of Sing Aluminum Composite Panels vs. Other Aluminum Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio |

Eco-friendly | |

| Sing Aluminum Panel | Y | Y | Y | Y | Y |

| Solid Aluminum | N | N | N | N | N |

| Aluminum Honeycomb | N | N | N | N | N |

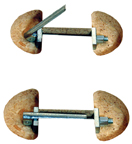

Easy to close edge, edge banding, install solid wood implant at any location which provide stronger bonding

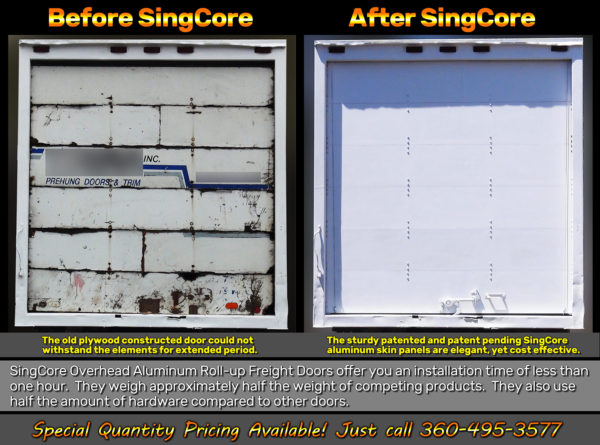

Case study.

Aluminum out door bench.

Veneer face aluminum door.

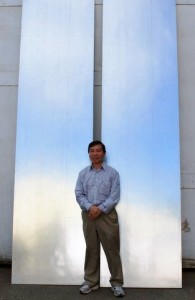

The longest, strongest, lightweight eco-friendly 37 ft x 3 ft aluminum panels shipped from Seattle to New York

|

|

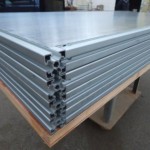

Sing Metal Panels

Sing Honeycomb Metal Panels are stronger and lighter than other metal panels, which can be dented by something as small as a golf ball.

The torsion box core holds the Sing Metal Panel flat so that it will not warp and sag. A 16lb steel hammer will easily dent a steel or vinyl door, but not a Sing Metal Panel. Because Sing panels are efficient to produce, they are more affordable than solid steel panels.

Advantange of Sing Metal Panels vs. Other Metal Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio | Eco-friendly | |

| Sing Metal Panel | Y | Y | Y | Y | Y |

| Solid Metal | N | N | N | N | N |

| Metal Honeycomb | N | N | N | N | N |

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features.

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features.

Sing Core Cold Rolled Steel Panels have a wide range of applications, are not limited in length or width and though we excel in large projects, we also provide solutions for reduced dimesions for smaller projects.

The example to the left is an application that was used in material handling. This trough is constructed with 20 gauge cold rolled steel and is used for moving raw material.

The image to the right is an example of a cut out that was made in the trough.

These are just a few examples of how Sing Core Cold Rolled Steel Panels are flexible and easy to use in a variety of applications.

See also Sing Core Metal and Sing Cold Rolled Steel Panels

- High precision workstations

- Retail office furnishings