Sing Post and Beam – A Smarter Way to Build

Sing Post and Beam changes how structures are built.

Traditional beams are heavy. However, Sing Post and Beam is lightweight.

Solid wood warps. In contrast, Sing Post and Beam stays straight.

Because of patented Sing Core technology, Sing Post and Beam delivers strength, stability, and ease of construction in one system.

How Sing Post and Beam Structures Are Built

The Sing Post and Beam system follows a simple process. As a result, construction becomes faster, safer, and more precise.

Step 1 — We Manufacture the Sing Post and Beam

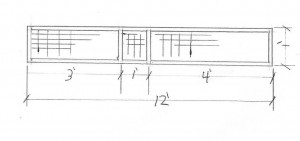

First, we build every Sing Post and Beam post using our patented core.

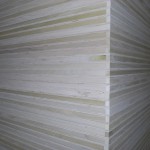

Inside each Sing Post and Beam is:

-

A vertical grain veneer torsion box

-

Structural skins

-

Lightweight EPS foam

-

Solid wood edging

Because of this structure, Sing Post and Beam products act like endless I-beams. Therefore, weight spreads evenly. As a result, the beam resists sagging.

Traditional posts fight gravity. However, Sing Post and Beam works with engineering.

So the benefits are clear:

-

Straight and warp-free

-

Strong yet lightweight

-

Resistant to weather

-

Stable through temperature changes

Most importantly, Sing Post and Beam posts remain dimensionally stable over time.

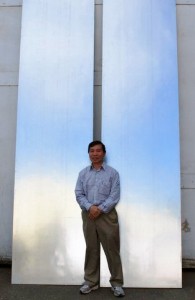

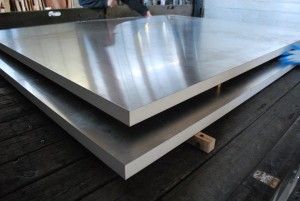

Lightweight Sing Post and Beam Structure

Sing Post and Beam can weigh as little as 30% of traditional materials.

Therefore, handling is easier.

Also, installation is faster.

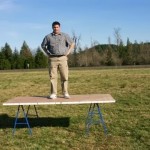

Step 2 — The Roof Structure Is Built on the Ground

Next, we assemble the roof frame using Sing Post and Beam beams.

Because the beams are lightweight, workers can handle them easily.

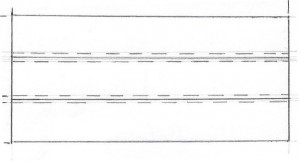

Also, because they are torsion box engineered, they stay flat.

Therefore, the roof structure goes together quickly.

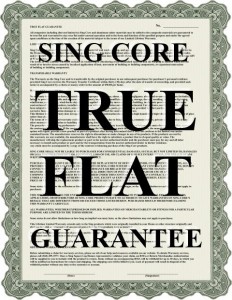

Traditional beams twist. However, Sing Post and Beam stays true flat within .007 inches.

As a result, alignment is easier. In addition, fewer corrections are needed later.

So, we build the entire Sing Post and Beam roof system safely on the ground.

Step 3 — Forklifts Lift the Sing Post and Beam Roof

Then, the full roof structure is lifted.

Because Sing Post and Beam is lightweight, forklifts can raise the entire assembly.

In contrast, traditional materials would require complex lifting plans.

Furthermore, torsion box rigidity keeps the frame stable during lifting.

Therefore, placement becomes smooth and controlled.

Step 4 — The Roof Lands on Four Sing Post and Beam Supports

Now, the structure comes together.

The lifted roof is set onto four primary Sing Post and Beam posts.

Because of long-span strength, fewer supports are needed.

As a result, open interior space increases.

Moreover, load spreads across the engineered core.

Therefore, deflection stays low.

Also, geometry remains stable.

No settling. No twisting. Or warping.

Step 5 — Walls Are Added to Complete the Sing Post and Beam Structure

After the Sing Post and Beam frame is in place, walls are added.

Since the structure carries the load, walls are simply enclosure.

Therefore, design flexibility increases.

Sing Post and Beam systems are ideal for:

-

ADUs

-

Workshops

-

Garages

-

Studios

-

Modular structures

-

Additional buildings

- Why Sing Post and Beam Performs Better

Sing Post and Beam Dimensional Stability

Solid wood moves. However, Sing Post and Beam stays straight.

Because of torsion box engineering, movement is minimal.

Sing Post and Beam with Built-In Insulation

Sing Post and Beam includes insulation values from R 3.5 to R 6.5.

In contrast, solid wood provides far less.

Precision

Sing Post and Beam remains flatter than solid lumber.

Therefore, fit and finish improve.

Weather Resistance

Additionally, Sing Post and Beam resists rot and moisture.

So long-term performance improves.

Engineering and Testing Behind Sing Post and Beam

Sing Post and Beam was developed through testing.

Load testing confirmed strength.

Deflection testing confirmed stiffness.

Environmental testing confirmed stability.

Because of this development, Sing Post and Beam solves major building problems:

-

Excess weight

-

Warping

-

Material movement

-

Structural inefficiency

The Advantage of Sing Post and Beam

Sing Post and Beam changes workflow.

First, build on the ground.

Next, lift once.

Then, set in place.

Finally, add walls.

Faster. Safer. Lighter. Stronger.

That is why Sing Post and Beam is redefining structural construction.

*** GET AN ESTIMATE TODAY!!! ***

Ready to see what your project would cost? You can get a fast, personalized quote for your Sing Post and Beam structure directly from the source. Simply visit the Sing Core estimate page to share your project details, sizes, and specifications. From ADUs to large-span structures, the team will review your needs and provide pricing based on your exact design. Start here to request your estimate: https://singcore.com/pricing-3/get-an-estimate

See more of what Sing Core has to offer

See how Sing Core technology powers oversized, lightweight, warp-free doors at https://10ftdoors.com/.