Applications -> Building Components -> Doors -> How to Build Doors

Stronger than Steel,

Lighter than Wood

Doors do not have to be made out of steel to be rigid and strong. Sing Core doors are stronger and lighter, than steel and vinyl doors. Standard steel overhead garage doors are made of steel so thin that a golf ball can dent it. This is not the case with Sing Core doors. We offer higher quality doors at prices competitive with steel doors with quality superior to wooden doors.

Sing Core doors are more stable, provide better insulation, and are far lighter than solid wood doors. The torsion-box core holds the Sing Core door flat, ensuring that that the panel will not warp and sag like ordinary wood.

Patented Sing Door Methods

Sing Core doors are versatile and customizable. Every order is custom designed with the client’s project in mind. Each door is constructed using methods that specifically cater to our customers’ individual needs. We construct our doors using the following methods: pole barn grade, paint grade, wood grain grade, and plank grade.

How We Build Our Doors

The easiest way to build the best doors.

Step 1 – Apply Glue to the Skin

Step 2 – Build Solid Wood Frame

Step 3 – Install the patented Sing honeycomb torsion box core & press on the skins.

Step 4 (optional) – Cut hole for window and prepare window trim.

Step 5 (optional) – Install glass and finish the door to desired look and function.

Step 6 – Install the door onto jam.

How We Build Our Stile and Rail Doors

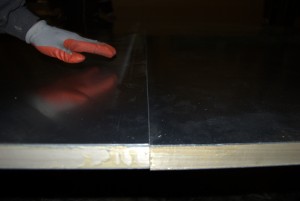

On the left are patented Sing honeycomb stile and rail. On the right is veneer (walnut) ready for gluing onto the patented Sing honeycomb stile and rail.

Apply glue to our patented Sing honeycomb stile and rail.

Press veneer to patented Sing honeycomb stile and rail. Most honeycomb panels cannot handle the high pressure and temperatures of the hot press, Sing honeycomb can.

Stile and Rail after the veneer has been pressed on.

See how straight the patented Sing honeycomb stile and rail are, yet they are still incredibly strong and lightweight.

Drill holes to accept dowels.

Doweled and glued.

Router out the end if hardware is to be installed

Stained and ready for glass and installation.

|

|

|---|

Pictures courtesy of Robert Shaw – www.robertshawmfg.com

Doors 8′ – 7″ tall