Modular Exhibit Systems

The most proficient exhibitors spend a great deal of money when they attend an exhibition show. Exhibit manufacturers expend a great deal of effort to make certain their customers have the high end representation they expect because their image and reputation (both the exhibitor and the manufacturer) depends on the impression made at the exhibition.

Sustainability is an issue if you’re constructing a high end display on site, then basically disposing of it. While the new exhibit is being built for the next exhibition to be attended (assuming you’re attending more than one exhibit per year).

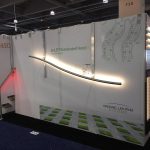

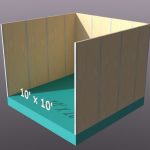

Modular Trade Show Displays

Enter modular trade show displays which are an Eco-friendly approach to expensive exhibit systems that are effective but inefficient.

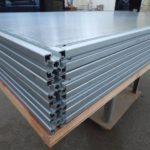

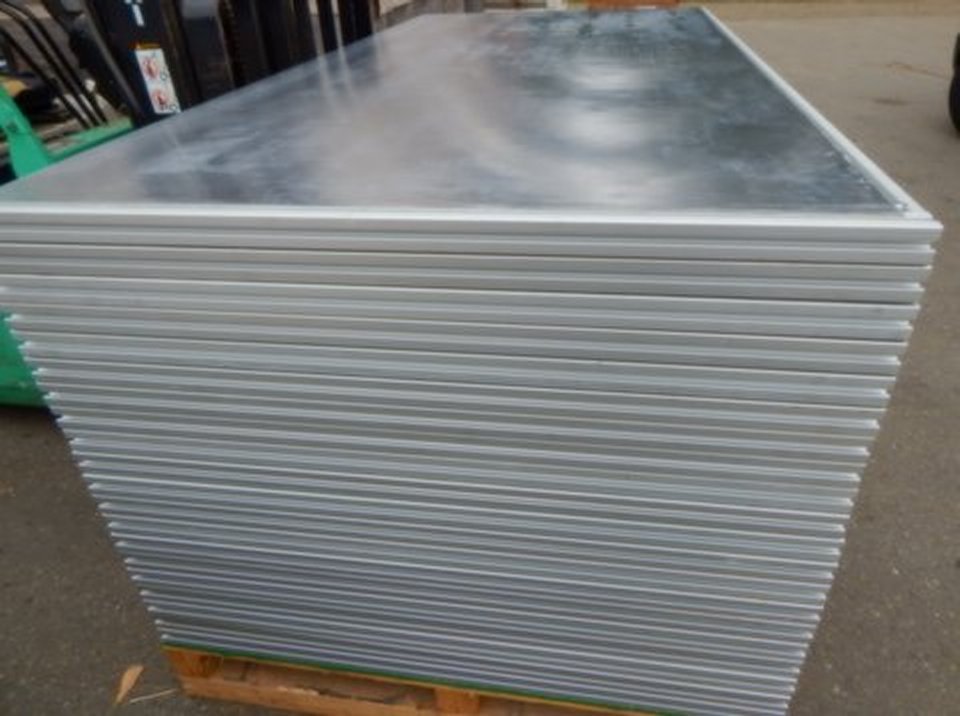

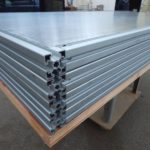

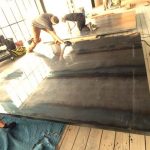

A modular exhibit system offers huge benefit for the exhibitors who use them. Their modular design is based on interlocking lightweight, high-strength panels that interlock. These exhibit systems can easily be assembled by one or two unskilled laborers in any configuration you desire.

Once assembled the exhibitor may apply exhibit signage or vinyl wrap, just like a custom build, only after the exhibition event, the booth materials are disassembled and stacked (flat packed) and transported to the next event for reassembly on site.

The custom case could be flipped over and used as a portable trade show counter, making it an active component within the exhibit when unpacked and assembled.

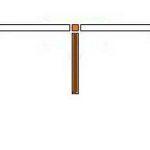

Easy to Assemble Exhibition System

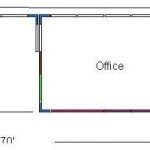

How easy is it to assemble a Sing Modular Exhibit System? So easy in fact that this one person (with very little help) assembled this 70 ft trade show display in little more than half-an-hour (see time lapse video).

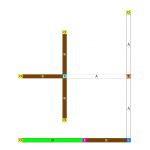

Individually Customizable Exhibition Components

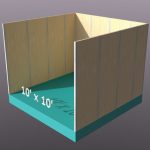

Whether you’re using your modular exhibition system for a stylish museum display, art show, product demonstration, training seminar, trade show display or temporary in plant office space, you can customize your exhibition components to meet your architectural specifications regardless of your trade show booth sizes. Your individual components can be manufactured to any size (height/length, width and thickness) to achieve the high precision results you desire.

Economy Standard Modular Trade Show System

For the more economically-minded and frugal exhibitor, we try to maintain a regular inventory of our standard modular trade show components in stock, which require little or no lead time, otherwise your custom trade show panels may require four to six weeks for delivery.

See: Standard Modular Trade Show System

Modern Trade Show Booth

Imagine owning your own high end modern trade show booth that could be lightweight, easily transferred, assembled, disassembled, stored and reconfigured live during the exhibition event.

In between shows, your modular exhibit system is safely stored away, ready for the next exhibition.

And if your company grows, from a 10 ft x 20 ft exhibit space to a 10 ft x 70 ft piece of exhibit real estate, no problem. Just add the modular trade show components you need to expand the system you already have. No need to buy a new exhibit system (unless you want to), making your Sing exhibit system the ultra modern trade show booth. The only

Modular Exhibit Systems Guaranteed 50 Years

Only premium modular exhibit systems and trade show displays can be guaranteed warp-free including full structure warranty for a full 50 years.

That means your investment in SingCore exhibit systems are intended to far exceed the life of any other trade show displays and effective return on investment (ROI).

Easily Repairable

With such a long life, you might be concerned about the eventual damage to a Sing modular display panel. Again, no problem; unlike other trade show display panels, a Sing Panel can be repaired (for instance, if forklift forks were run through it) and returned to its original condition without compromising the strength of the original panel.

Oversized Doors

When it comes to oversized doors, don’t you want your doors to be low maintenance and warp-free?

When it comes to oversized doors, don’t you want your doors to be low maintenance and warp-free?

Thanks to the invention of our patented non-warp solution any door of any size can be a warp-free door if it has SingCore inside.

Oversized Doors Challenge

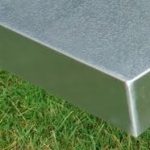

The trouble with oversized doors today is that all over the USA and around the world if the doors are large doors – over 7 ft. tall and 3.5 ft wide – problems will arise causing the door to fail because all big doors warp. That’s the basic problem and SingCore solves that problem quite nicely.

If your oversized door has professional SingCore inside it can be guaranteed to be warp-free for 50 years, including full structural warranty. No other door can be guaranteed to be warp-free unless it has SingCore inside.

The Secret of Warp-free Oversized Doors

The secret of creating warp-free oversized doors is out, and SingCore is the answer. Besides being guaranteed warp-free for 50 years, your high quality doors with SingCore inside offer other features eluding doors manufactured any other way. You can expect some amazing additional attributes due to the composite structure of SingCore door blanks. For instance:

The secret of creating warp-free oversized doors is out, and SingCore is the answer. Besides being guaranteed warp-free for 50 years, your high quality doors with SingCore inside offer other features eluding doors manufactured any other way. You can expect some amazing additional attributes due to the composite structure of SingCore door blanks. For instance:

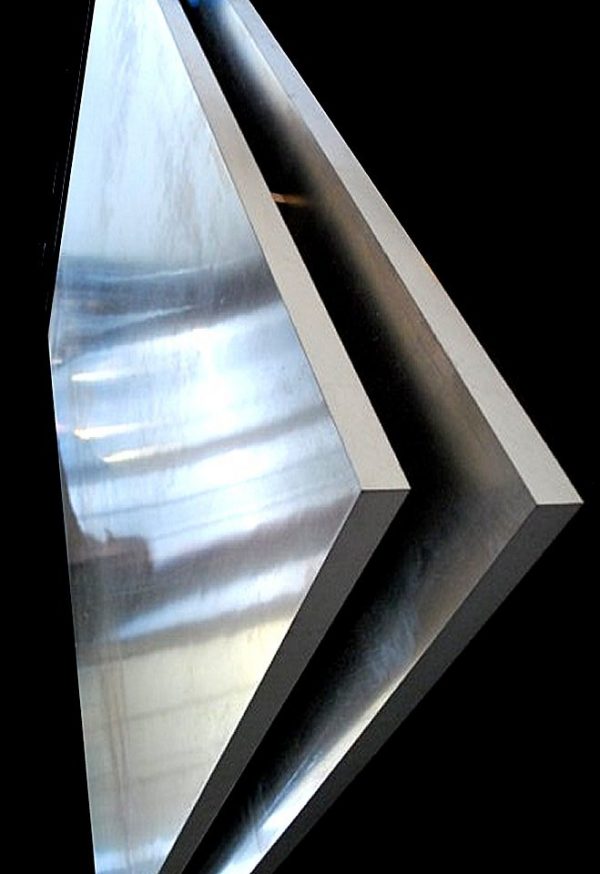

Lightweight: SingCore is a solid internal door core designed for oversized doors that weighs a fraction of other solid wood door cores. Oversized doors with SingCore inside can weigh 100 lbs. each in comparison to the 1,100 lbs. each of the original solid core large doors being architecturally replaced.

High Strength: SingCore has been independently tested and rated at 660 PSI. That’s stronger than steel pound-for-pound. No other lightweight door core material is stronger or more effective for oversized doors that can withstand over 600 lbs.

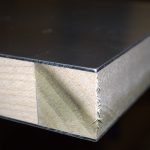

Will Not Warp, Bend or Twist: Professional SingCore will not warp, bend, twist or otherwise fail due to the vertical grain torsion box structure reinforced with rigid structural strength foam insulation and patent pending stiffeners. Sandwiched between two stress skins SingCore is the only door core material than can be guaranteed warp-free for 50 years.

Will Not Warp, Bend or Twist: Professional SingCore will not warp, bend, twist or otherwise fail due to the vertical grain torsion box structure reinforced with rigid structural strength foam insulation and patent pending stiffeners. Sandwiched between two stress skins SingCore is the only door core material than can be guaranteed warp-free for 50 years.

Insulated: SingCore is packed with insulation for climate control and sound deadening characteristics ranging from R3.5 and up per inch due to the structural insulation used inside the torsion box structural grids. Foam can be upgraded from our standard EPS foam (R3.5) for even more insulation per your specifications by using Polyurethane foam (R6.5), Polyisocyanurate (R7.5), Phenolic (over R8) or other more advanced foams that may be available to meet your specifications, while solid wood is rated at R.71 to R1.4 per inch.

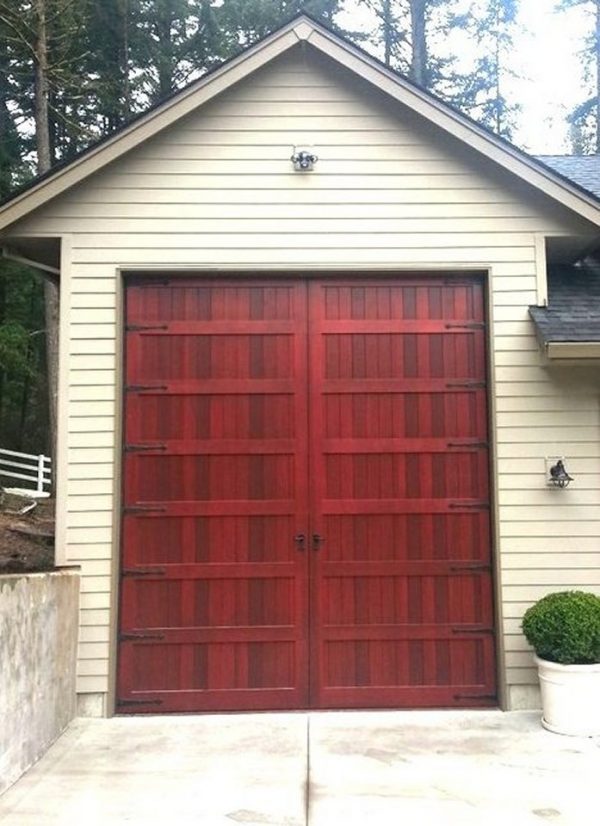

Oversized Garage Doors

When garage door companies create a warp-free insulated exterior 10 ft garage door that stands between the garage door interior and fully exposed to the elements only one high quality large garage door solution can be guaranteed to be warp-free for 50 years. And 8 ft. doors are child’s play for SingCore, the only exterior garage door material that can pack such an impressive warranty. So, if you have a large garage with oversized garage doors and you want worry-free long life and low maintenance, tell your garage door manufacturer, you want, “SingCore inside.”

When garage door companies create a warp-free insulated exterior 10 ft garage door that stands between the garage door interior and fully exposed to the elements only one high quality large garage door solution can be guaranteed to be warp-free for 50 years. And 8 ft. doors are child’s play for SingCore, the only exterior garage door material that can pack such an impressive warranty. So, if you have a large garage with oversized garage doors and you want worry-free long life and low maintenance, tell your garage door manufacturer, you want, “SingCore inside.”

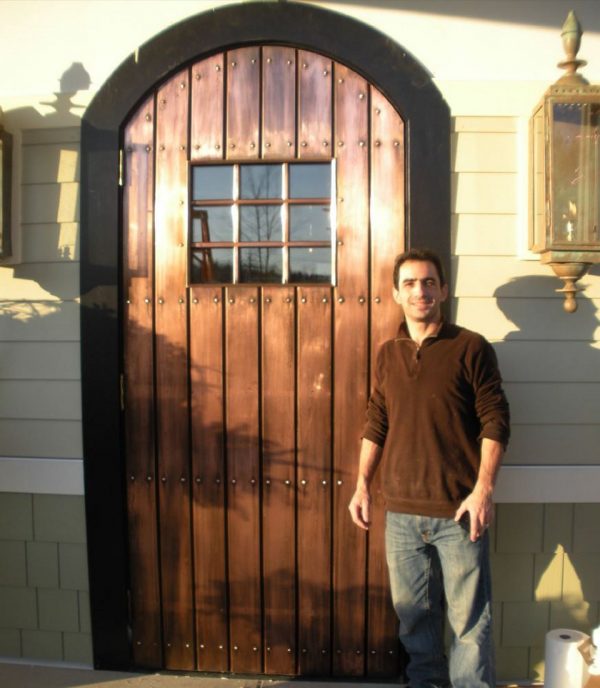

Oversized Front Door

Not unlike oversized garage doors, the oversized front door is the number one most important access point in the home. Being oversized exterior doors, the importance of lightweight, high strength, warp-free and highly insulated adds to the overall safety and security of the home protecting the family from exterior noise, weather conditions, energy loss, and intruders while maintaining secure, uncompromised door seal. Quite a feat for any oversized doors, and are the only oversized entry doors that can be guaranteed for 50 years.

Oversized Sliding Doors

Oversized sliding doors are the most important oversized doors to keep warp-free for long-term maintenance-free operation, because if the large sliding door were to warp, bend or twist the door becomes damaged or inoperable. This is especially true for oversized pocket doors which are concealed within a hidden compartment inside the wall, when in the open position and warped, may not be easily withdrawn from its resting place when opened, or alternatively may not be opened due to not being able to retract into its predetermined location.

Oversized sliding doors are the most important oversized doors to keep warp-free for long-term maintenance-free operation, because if the large sliding door were to warp, bend or twist the door becomes damaged or inoperable. This is especially true for oversized pocket doors which are concealed within a hidden compartment inside the wall, when in the open position and warped, may not be easily withdrawn from its resting place when opened, or alternatively may not be opened due to not being able to retract into its predetermined location.

Guaranteed Oversized Doors

Prior to the introduction of SingCore to the oversized door builders, door manufacturers and millworks found it impossible to offer any warranty on 8 foot doors, 10 ft garage doors or even larger doors. Now, thanks to SingCore, they can build and offer a warranty on doors to remain warp-free for 50 years, even if the oversized door spans 50 ft.

Temporary Exterior Walls

You never know when you might have the need for temporary exterior walls for added safety and security, in natural disaster management, construction, as barricades, for temporary offices or parking lot structures.

Your options are limited to transporting temporary structures to the site location, building temporary structures from scratch, or designing and using modular temporary exterior wall components to store and have on-hand when needed.

Lightweight Temporary Exterior Walls

Regardless of the desired surface materials, your Sing temporary exterior wall weigh-in at a fraction of the weight of their heavily constructed alternatives. The resulting lightweight exterior wall panels are easy to manipulate, stack, transfer and store. The light weight also saves on energy consumption both on the road and at the job site.

High Strength Temporary Exterior Walls

Other honeycomb-type lightweight structural material is not built to last and does not possess much in the way of strength (10 to 110 PSI) while SingCore has unparalleled strength (660 PSI) stronger than steel pound for pound.

Temporary Exterior Wall Versatility

Your temporary exterior walls can be built to your custom architectural specifications and manufactured with any desired flat building material such as any wood species, metal (aluminum, cold rolled steel, copper, galvanized steel, hot rolled steel, stainless steel, etc.) or other material (concrete, fiberglass, FRP, glass, HPL, Kevlar, Lexan, LVL, MDF, etc.).

Your temporary exterior wall panels can be custom designed and built to any size (height/length, width, thickness) for protection from the elements, dust, climate control, remodeling, and infection control for hospitals, disaster relief or other industrial applications.

Flat Pack for Transfer and Storage

All Sing temporary exterior wall components conveniently flat pack for the best management of space and less transportation costs.

Easy to Assemble Temporary Exterior Walls

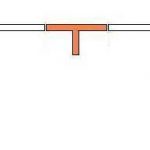

Unlike on site building, using SingCore modular temporary exterior walls to fabricate the secure space necessary is as simple as snapping the components together with cam-lock interconnects that are high precision and easy to assemble. The only tool required for assembly, a simple Allen wrench.

Your temporary exterior walls can be used as a moving wall, or reconfigured on-site to manage obstruction, create separation, increase privacy and security or maintain effective control of traffic flow.

Reusable Temporary Exterior Walls

Sustainability and efficiency are maximized by saving energy and waste as Sing temporary exterior walls can be used over and over again, and in the event of on-site damage, are easily repaired without compromising the exterior wall panel’s structure strength.

Wall Temporary Wall System

Basically, your temporary wall ideas can be unleashed in conjunction with the professional design staff and SingCore who will help to educate your staff in how to design and how to build a temporary wall that will meet or exceed your high performance expectations and specifications.

- Sing Core bookshelf

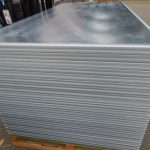

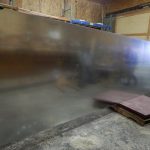

Insulated Aluminum Panels

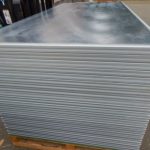

America’s premier Insulated Aluminum Panels are lightweight, high strength, and have insulation R value that is variable to meet your project’s requirements and can be guaranteed to be fail-free for 50 years all thanks to having patented Sing Core inside. No other insulated aluminum panel can compare to Sing Core’s premium strength (660 PSI), high precision (+/- .006 inch) and high performance (full 50 year warp-free and structural guarantee) making them the best architectural insulated aluminum panels made in the USA.

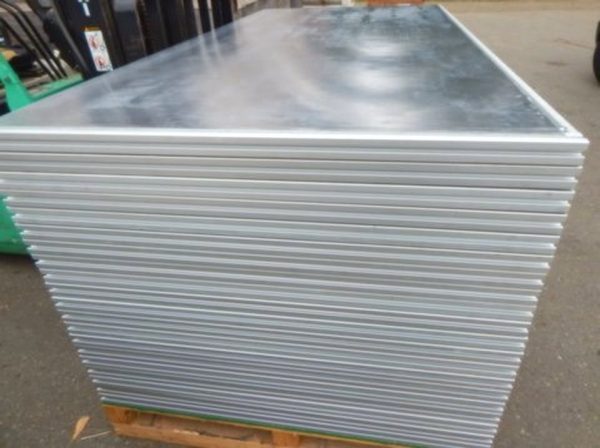

Low Cost 4’x8′ Aluminum and 4’x10′ Honeycomb Structural Panels

Our low cost, standard sized 4’x8′ and 4’x10′ aluminum panels cannot be beat in terms of price and value. While maintaining all the strength, durability, and longevity of our more expensive custom panels, these mass produced variety can be had for a fraction of the price.

Our low cost, standard sized 4’x8′ and 4’x10′ aluminum panels cannot be beat in terms of price and value. While maintaining all the strength, durability, and longevity of our more expensive custom panels, these mass produced variety can be had for a fraction of the price.

Previously thought impossible, thanks to great steps forward in manufacturing prowess, mass produced Sing Core aluminum honeycomb panels are flooding the market!

Now Click for Price for a 4’x8′ panel.

| Size | Sqft |

|---|---|

| 4’x8′ | 32sqft |

| 4’x10′ | 40sqft |

| over 4’x10′ | any size |

Patented Insulated Aluminum Panels

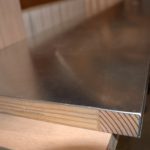

Our patented insulated aluminum panels are a composite reinforced structural insulated panel (RSIP) not to be confused with a standard SIP panel, which is not as structurally sound as the Sing Core Reinforced SIP. The secret is that all Sing Core RSIPs feature patented Sing Core inside, which is a torsion box/rigid foam insulation hybrid structural core imbuing these insulated aluminum panels with their unprecedented strength, tested independently to be able to withstand stress upwards of 660 PSI, high precision and performance.

Architectural Insulated Aluminum Panels

Sing Core insulated aluminum panels are not an off-the-shelf generic product. Every architectural insulated aluminum panel is custom manufactured to architectural specifications in any size, length, width and thickness. Starting at R3.5 per inch the rigid foam insulation can be exchanged to increase insulation R value to meet your specifications and aluminum exteriors are available in any standard colors or can be custom painted or finished.

Aluminum Shelf, Raised Floor for Mercedes Van

You could use Sing Core aluminum panels inside your private or commercial vehicles to make ease of accessing and organizing cargo, as aluminum shelves, or as aluminum raised flooring.

Pictures (above) depict inside of van project for increasing ability to handle and sort cargo in transit.

For more information about James Abke’s Mercedes portable home van conversion, see it here: http://singcore.com/news/sing-core-and-james-abke-turn-mercedes-van-into-portable-home.

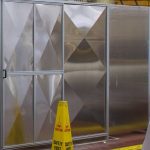

Metal Wall

One of the most popular applications for Sing insulated aluminum panels is used in energy efficient metal wall projects including metal storefronts, aluminum in-fill panels and aluminum glazing panels. These architectural insulated aluminum panels are custom manufactured to your architectural specification in terms of panel size (up to 50 ft. in length) and can feature any available painted and anodized colors for maximum visual impact, whether utilized in interior or exterior metal wall applications.

Insulated Wall Panels

Sing insulated aluminum panels can be found in high end architectural, commercial, industrial and cold storage markets where high precision and performance are second to none and the end users demand only the very best Eco-friendly building materials. The insulation is customizable giving you complete control of wall insulation R value which improves moisture, temperature and environmental conditions while also adding sound deadening characteristics.

Building Envelopes

Commercial projects using Sing Core insulated aluminum panels as part of the exterior building envelope are not restricted by adhering to a standard product as every metal building insulation panel is custom built in our Pacific Northwest factory to architectural specifications. This allows unbridled creativity and design freedom as panels are nor restricted by size, shape or thickness. Whether your project is a high-tech renovation or an exclusive high-rise project, Sing Core can supply the insulated panels to match your specs. Be aware, since we do not build a standard product, we do not have an engineer-stamped and approved panel, so the project’s engineering staff will be responsible for approval and rating any Sing Core insulated metal building products.

High Precision

Advantages of Sing Core’s high precision (+/- .006 in.) and high performance (low maintenance and warp resistance) include maintaining a structurally sound uncompromised airtight seal. This is especially advantageous when maintaining a sustainable energy efficient structure or clean room, whether as a permanent installation or modular portable structure.

We have the best precision of any manufacturer in the world. No one can come close to our methods of manufacturing the most precise, dimension-ally stable panels. This is called “mission impossible.” No one else can do this!

Trade Professionals

Serving architectural, commercial, industrial and institutional markets, Sing insulated aluminum panels are patented source building material available to architects for specification in projects serving the most discriminating clientele, contractor, metal fabricators and millworks throughout the United States and abroad. Architects and other high end professionals choose our panels because they have come to expect quality and unbeatable strength and light weight nature. Our panels beat the competition by miles. No one else can make insulated aluminum panels as straight, high strength, and warp free as ours.

- Aluminum metal doors strength test

Bi-fold Garage Door

Architects and designers are setting new trends by specifying architectural bi-fold garage doors. The attention getting bi-fold garage door designs in high-end architecture create an unprecedented visual impact while exuding charm and elegance. Bi-fold garage doors are lighter in weight than swing-out doors so they can be larger and not opening out as far, leaves more useable space.

Large bi-fold carriage door panels fabricated by Sing Core, finished and installed at private residence in Portland, Oregon by Best Overhead Door.

Bi-folding garage doors open on themselves, featuring a pair of door slabs folding and stacking to the edges of the opening (like folding closet doors) for maximum access. It also takes less time to open and/or close bi-fold garage doors than full out swing or overhead doors. Bi-fold garage doors can be opened manually or automatically. High precision perimeter seals are available to ensure separation from the elements when your bi-fold garage doors are in the closed position.

Residential bi-folding garage doors can run in garage door opening sizes of 7 ft. x 7 ft. to 24 ft. x 24 ft. and are custom built to accommodate any size garage door opening, regardless of door height or width, to ensure a perfect fit. Commercial users of automatic bi-fold garage doors include fire stations, auto dealerships, and parking garages.

Wood Bi-fold Garage Doors

Wood bi-fold garage doors are by far the most popular, can represent any type of garage door style or appearance offering the design team the greatest amount of leeway to exercise their full range of creativity and ingenuity.

Using a natural material like wood for example, can pose problems due primarily to the nature of the wood grain’s tendency to move according to environmental changes in temperature and moisture, resulting in compromise of your bi-fold garage door’s premium door seal.

One of the advantages of having patented solid Sing Core inside your bi-fold garage door is to prevent the warping of natural wood for a long life and maintenance-free enjoyment of your upscale garage door investment dollars.

Industrial Bi-fold Garage Doors

In the case of industrial bi-fold garage doors, wood can be used for ornamental appeal, though industry seems to gravitate toward steel, aluminum and in some cases fiberglass reinforced plastic (FRP). Industrial bi-fold garage doors are more likely very large in size and can run into openings 50 ft. x 20 ft. up to 100 ft. x 30 ft.

Horizontal Bi-fold Garage Door

Most residential bi-fold garage doors open horizontally, side to side. The operation of the bi-fold garage door opening is part of the visual appeal of the horizontal bi-fold garage door. Plus, it gives full overhead clearance, unlike a vertical operating garage door or overhead door when it is not in the fully opened opposition.

Vertical Bi-fold Garage Door

Bi-fold garage door are also available in vertical operation, where the folding doors articulate upward as leaves alternatively fold upon themselves. Vertical bi-fold garage doors are more popular in commercial and industrial applications, and also serve as an awning when in the open position, as in the case of aircraft hangar doors.

Custom Bi-fold Garage Doors

While some door manufacturers do import and/or manufacture bi-folding garage doors as prebuilt stock items, the majority of bi-fold garage doors are designed and built by highly specialized craftspeople and custom door manufacturers and millworks.

Sing Core Bi-fold Garage Door

Door blanks can be pre-cut for visual lite openings and can come pre-fabricated with nearly any available exterior flat building material including, but not limited to; any natural wood species, aluminum, brass, cold rolled steel, concrete, copper, fiberglass (FRP), galvanized steel, glass, hot rolled steel, LVL, any metals, and even stainless steel.

Insulated Bi-fold Garage Door

When your bi-fold garage door is built with Sing Core inside, you get the added benefit of have your door slabs fully insulated. Packed with insulation inside, you get the advantage of added climate control (R3 to R6.5 per in.) and sound deadening qualities without having the added expense of installing aftermarket garage door insulation panels for your garage door.

High Precision Bi-fold Garage Door

Bi-fold garage doors up to 7×7 have fewer maintenance concerns over time, but when they exceed these dimensions they are more prone to fail due to warping, bending, twisting and cupping which can be an issue in preserving separation from the elements and maintaining a complete door seal.

If your bi-folding garage doors have Sing Core inside, you can build a large bi folding precision garage door any size, up to 100 ft. or more without risk of compromise or failure.

Thanks to Sing Core’s high precision (+/- .006 in.) and resistance to warp, your bi fold garage doors can be guaranteed remain structurally sound and warp-free for 50 years. No garage door company can offer a guarantee like this unless your garage door has Sing Core inside.

Click for How to Build a Non-warp Carriage Door

16 foot garage door

- 16 ft Automatic Bi Fold Garage Door

- Thin Bi Fold Panels

- Accurate Panel Insure Tight Fit Bi Fold Doors

- Insulated honeycomb bi fold door

- Wood-Skin Sing Panel Exterior Doors

- Aluminum Bi Fold Garage Doors

- Over-sized honeycomb sandwich bi fold door

Exterior Door Blanks

Patented SingCore makes the best exterior door blanks in the United States of America. Architects, designers, contractors, millworks and door companies come to SingCore for exterior door blanks that outperform other door blanks used in exterior doors.

Patented SingCore makes the best exterior door blanks in the United States of America. Architects, designers, contractors, millworks and door companies come to SingCore for exterior door blanks that outperform other door blanks used in exterior doors.

Why SingCore Exterior Door Blanks?

The answer is

If you want the best exterior door

Start with the best exterior door core

SingCore exterior door blanks are the only door substrate with SingCore inside. Exterior doors of any size with SingCore inside are lightweight, high strength, insulated exterior doors that can be made with any door skin material, including outdoor wooden doors that can be guaranteed not to warp, bend, twist or otherwise fail for fifty years.

SingCore exterior door blanks are the only door substrate with SingCore inside. Exterior doors of any size with SingCore inside are lightweight, high strength, insulated exterior doors that can be made with any door skin material, including outdoor wooden doors that can be guaranteed not to warp, bend, twist or otherwise fail for fifty years.

Oversized Entry Doors

When it comes to large oversized doors, Sing door blanks help high end millworks and door companies to supply their clients with the biggest doors with full confidence of providing a oversized exterior that will not fail. Until SingCore exterior door blanks, the common response of door manufacturers was

We don’t build oversized doors

Large doors were any door over seven feet tall or three-and-a-half feet wide. Why? Because they warp; but if they were built not to warp they would be too heavy, causing regular maintenance calls for hardware repair and the heavy door caused extra stress and strain on the both the structure and the frame. Either way, big doors were a headache for both the door company and the end user.

Large doors were any door over seven feet tall or three-and-a-half feet wide. Why? Because they warp; but if they were built not to warp they would be too heavy, causing regular maintenance calls for hardware repair and the heavy door caused extra stress and strain on the both the structure and the frame. Either way, big doors were a headache for both the door company and the end user.

When using Sing exterior door blanks, any exterior doors – even exterior wood doors – can be guaranteed not to fail for 50 years.

Outdoor Wooden Doors

A wood exterior door is problematic due to the nature of the wood grain itself. The grain will either expand or contract due to changes in the environment and change in temperature or moisture will cause the wood to move this way or that. Moving or warping exterior wood doors compromise the door seal, and could prevent the exterior door from latching properly, or in extreme cases, closing at all.

Sing exterior door blanks are wood door skin panels that prevent the failure of any door regardless of exposure to the elements if made with professional warp-free SingCore with wood stave applied using the patented non-warping process.

Sing exterior door blanks are wood door skin panels that prevent the failure of any door regardless of exposure to the elements if made with professional warp-free SingCore with wood stave applied using the patented non-warping process.

Door Skin

Patented SingCore can host any exterior door skin material – not just solid wood stave – a welcomed feature to any designer or full service custom door builder. Sind you are not limited to wood door skin panels, your doors can be made of any flat building material, such as aluminum, cold rolled steel, concrete, copper, fiberglass/FRP, galvanized steel, hot rolled steel, HPL, Kevlar, LVL, metal or stainless steel, just to name a few.

Of course, now you can make doors of any available natural wood species warp-free with SingCore inside.

Insulated Exterior Doors

Another unique feature and added benefit of having SingCore inside your oversized entry doors is being able to enjoy having insulated exterior doors which means better energy savings and climate control. Also, because Sing exterior door blanks are packed wall to wall with rigid insulation as part of the torsion box composite solid door blank adding sound dampening qualities for added safety and security at no extra charge; all part of the design.

Solid Core Door Blanks

Solid Core Door Blanks

Sing exterior door blanks are a solid core door material made of natural vertical wood grain torsion box/foam composite yielding exceptional displays of strength with unparalleled resistance to deflection and warping. SingCore is so strong, that it was rated at over 660 PSI when independently tested by the University of Washington. That’s stronger than steel, pound for pound.

The inventor says, “Kick any other door and you break the door. Kick a Sing door and break your leg.”

Don’t break a leg, but do specify “SingCore inside,” when you want the best exterior door of any size that is insulated, lightweight, high strength and can be guaranteed for a full fifty years.

- Cedar

Millworks

See: AWI Millworks

| California | ||

| C T Finishing, Inc. | Pomona, CA | (909) 629 7402 |

| Crestmark Architectural Millworks | Arcata, CA | (707) 822-4034 |

| Mission Bell Architectural Millwork | Morgan Hill, CA | (408) 778-2036 |

| Connecticut | ||

| A. Secondino & Son, Inc. | Branford, CT | (941) 639 7188 |

| Amerifix | West Haven, CT | (203) 931 7290 |

| Florida | ||

| Adams Group | North Port, FL | (203) 481 3496 |

| Akira Wood, Inc. | Gainesville, FL | (352) 375 0691 |

| Andy’s Cabinets and Millwork Inc. | Tallahassee, FL | (850) 562 3536 |

| Blumer & Stanton, Inc. | West Palm Beach, FL | (561) 585 2525 |

| Hawaii | ||

| Bruce Matson Company, Inc. | Honolulu, HI | (808) 380 9414 |

| Idaho | ||

| Advanced Woodworking Industries (AWI) | Hayden, ID | (208) 772 2377 |

| Anderson Cabinet & Millwork | Rigby, ID | (208) 538 7415 |

| Illinois | ||

| Ameriscan Designs, Inc. | Chicago, IL | (773) 542-1291 |

| Benchmark Cabinets & Millwork, Inc. | Peoria, IL | (309) 697 5855 |

| Bernhard Woodwork, Ltd. | Northbrook, IL | (847) 291 1040 |

| ONSITE Woodwork | Loves park, IL | (815) 633-6400 |

| Indiana | ||

| Advanced Cabinet Systems | Marion, IN | (765) 677 8000 |

| Antreasian Design, Inc. | Indianapolis, IN | (317) 546 3234 |

| Iowa | ||

| A.F. Johnson Millwork Company | West Des Moines, IA | (515) 277 7222 |

| Kansas | ||

| Allen Millwork Company | Wichita, KS | (316) 943 5151 |

| Kentucky | ||

| America’s Finest Woodworking Team Inc | Lexington, KY | (859) 254 8999 |

| Louisiana | ||

| C & C Millworks, Inc. | Baton Rouge, LA | (225) 273 1258 |

| Woodward Millwork Group | Goodbee, LA | (985) 871-7723 |

| Maine | ||

| Duratherm Corporation | Vassalboro, ME | (207) 872-5558 |

| Maryland | ||

| Baker & Kerr, Inc. | Upper Marlboro, MD | (301) 390-1090 |

| Massachusetts | ||

| Sterling Architectural Millwork | Springfield, MA | (413) 732 2131 |

| South Shore Millwork, Inc. | Norton, MA | (774) 225-6300 |

| Woodmeister Master Builders | Holden, MA | (774) 345-1000 |

| Michigan | ||

| Advantage Millwork | Wyoming, MI | (616) 248 7908 |

| Allen Bradley Interiors Inc. | Rhodes, MI | (989) 689 4133 |

| BJC Services Inc | Chesterfield, MI | (586) 783 4559 |

| Burke Architectural Millwork | Livonia, MI | (734) 744 9492 |

| Minnesota | ||

| Aaron Carlson Corporation | Minneapolis, MN | (612) 789-8885 |

| Missouri | ||

| A to Z Laminating Specialists Inc | Wentzville, MO | (636) 332 9961 |

| New Mexico | ||

| Antix, Inc. | Las Cruces, NM | (575) 526 2398 |

| New Jersey | ||

| B & M Custom Cabinetry | Blackwood, NJ | (856) 227 9248 |

| New York | ||

| Bauerschmidt & Sons, Inc. | Jamaica, NY | (718) 528 3500 |

| Beaver Creek Industries, Inc. | Canaseraga, NY | (607) 545 6382 |

| Deerfield Millwork | Water Mill, NY | (631) 726-9663 |

| Jim Illingworth Millwork | Adams, NY | (315) 232-3433 |

| Reilly Windows & Doors | Calverton, NY | (631) 208-0710 |

| North Carolina | ||

| Carolina Top Shelf | Charlotte, NC | (704) 376-5844 |

| Caseworx | Hudson, NC | (828) 212 0000 |

| Ohio | ||

| Amtekco Industries, Inc. | Columbus, OH | (614) 228 6590 |

| Oregon | ||

| Advance Cabinet Designs, Inc. | Eugene, OR | (541) 465 3394 |

| McFarland Door & Millwork | Lakeview, OR | (541) 947-5136 |

| Pennsylvania | ||

| Allegheny Millwork & Lumber | Pittsburgh, PA | (401) 721-5500 |

| Beam’s Custom Woodworking Inc. | Morgantown, PA | (610) 286-9040 |

| Bristol Millwork Inc. | Philadelphia, PA | (215) 533-1921 |

| Rhode Island | ||

| All State Fabricators | Cranston, RI | (401) 785 3900 |

| Artisan Millwork | Pawtucket, RI | (412) 431-4224 |

| Tennessee | ||

| ANA Woodworks, LLC | Chattanooga, TN | (423) 867 3171 |

| Texas | ||

| 21st Century Manufacturing | Houston, TX | (832) 593 0123 |

| 3V Company | Houston, TX | (281) 717 1200 |

| Abilene Millwork | Abilene, TX | (325) 677 8856 |

| Acacia Originals | Porter, TX | (832) 256-9631 |

| AEP Millwork | Arlington, TX | (817) 522-4542 |

| Bespoke Millwork | Houston, TX | (281) 598 4880 |

| Brochsteins | Houston, TX | (713) 666 2881 |

| HEWN – Joinery + Mastercraft + Fabrication | Austin, TX | (512) 386 6404 |

| Maverick Door and Millwork, Inc. | Schertz, TX | (210) 659-5553 |

| Robert Shaw Manufacturing | Fort Worth, TX | (817) 927-2557 |

| Utah | ||

| Boswell Wasatch Mill | Springville, UT | (801) 489 7527 |

| Virginia | ||

| Annandale Millwork and Allied Systems | Winchester, VA | (540) 665 9600 |

| Washington | ||

| AAA Cabinets & Millwork Inc. | Airway Heights, WA | (509) 484 7152 |

| Interior Environments | Seattle, WA | (206) 432-8800 |

| West Virginia | ||

| Allegheny Restoration & Builders Inc. | Morgantown, WV | (304) 381-4820 |

| Wisconsin | ||

| Eggers Industries | Two Rivers, WI | (920) 793 1351 |

| Kolbe and Kolbe Milllwork Co., Inc. | Wausau, WI | (715) 842-5666 |

CANADA

| Ontario | ||

| Harvest Creek Millwork | London, ON | (519) 680-7482 |

Wooden Room Dividers

When you’re looking to divide a space into two or more spaces, you may want to have more of a true separation between the spaces, while not having to rely on permanent construction and insulation contractors and installation, especially if you’re looking for temporary walls or room partitions that are modular components.

Temporary walls and room partitions made with SingCore inside have extraordinary characteristics drawing interest from individuals in New York seeking our wooden room dividers as the stand out lightweight, high strength, modern room dividers from 3,000 miles away. You might be surprised to learn we send more wooden products to New York than any other single location in the USA.

Temporary walls and room partitions made with SingCore inside have extraordinary characteristics drawing interest from individuals in New York seeking our wooden room dividers as the stand out lightweight, high strength, modern room dividers from 3,000 miles away. You might be surprised to learn we send more wooden products to New York than any other single location in the USA.

Sing wooden room dividers are built to architectural specifications using any of all available wood species though even inexpensive standard torsion box plywood panels available via the Lowe’s Home Improvement Pro Desk are the value-added low cost alternative for the DIY wooden room dividers for the creative do it yourselfer on a budget.

Large Wooden Room Dividers

The biggest wood room dividers present the greatest number of challenges for architects, designers and contractors. Unfortunately, while large wooden panels are highly sought out for their beautiful appearance, performance-wise they can be problematic. Due to the nature of the natural wood, the panel will tend to warp, bend or twist and there is little you can do about it, unless it has SingCore inside.

Warp-free Wooden Room Dividers

SingCore is the solution for creating a wood panel room divider that can be guaranteed warp-free for 50 years, even in a wood panel standing 37 feet tall, if built and designed correctly with professional SingCore. Non-warping wooden room dividers are not the only solution provided when your room partitions have SingCore inside. You also get:

Insulated wooden room dividers, providing greater room separation, climate control and sound deadening qualities for added safety, security and privacy between rooms.

Insulated wooden room dividers, providing greater room separation, climate control and sound deadening qualities for added safety, security and privacy between rooms.

Lightweight wooden room dividers, that are less expensive and easier to transport, handle and install (while cutting down on potential injuries caused by working with heavy wooden room dividers).

High strength wooden room dividers, offering incredible strength – even from an inch-and-a-half thick panel room divider – to support the installation of a custom door without compromising the space dividers.

Any Type or Style of Wooden Room Dividers

Wood temporary walls are designed for a wide variety of styles, uses and configurations to meet or exceed the expectations of the best architects and designers in the United States.

Pivot Door Wooden Room Dividers

The most popular configuration for temporary walls are room partitions made using pivoting – or a combination of pivoting and sliding – door hardware.

Sliding Wooden Room Dividers

A fairly straightforward way to temporarily divide a space would be to place sliding doors to separate an otherwise wide open area. When you want the space open, simply slide open the sliding door room dividers and you’re in business.

- Lightweight Modern Door

Bedroom Dividers

You will find the insulation and sound dampening abilities of your Sing wooden room dividers will help you get a good night’s sleep in your cozy new bedroom, while enjoying the redesigned space, yielding a high quality of life with the addition of more bedrooms without the cost of expensive contractors.

Moving Wall

Your wooden room dividers could be configured to fully open providing full access to the entire space, when collapsed or folded, or dividing the space into multiple areas serving different functions as you see fit. Some installations include electronically articulating wall components using automatic door hardware with optional remote controls.

Pressure Walls

While some people are using our standard torsion box panels as components in quick and easy pressure walls, our friends in the greater New York area are feeling the crunch of building codes being enforced, especially in Manhattan. For these people, they are reaching out for using our insulated panels as backing for shelves, creating a

Bookcase Wall

Even though bookcase walls are trending now in New York, designers, architects and engineers have been specifying SingCore as the backing material for bookcase walls for increased insulation and room separations when in use as a room divider disguised as a bookcase. In fact, entire bookcases built of SingCore can be easily pivoted with a standard pivot door hinge and used as a temporary wall or secret door which could be opened when desired or necessary, not just as the bookcase wall nyc.

- Sing Core bookshelf

- Sing Core bookshelf

Moveable Storage Unit Wall

The next step in alternative wooden room dividers is utilizing SingCore to build full modular storage units on wheels to make and create not only moveable storage components but to create sound deadening and functional room separation. Thanks to the lightweight and high strength these storage units can be moved around on furniture casters with ease.

- Walnut

- Bi-directional Walnut

- Marine Grade Ply

- Teak Door

- Walnut

- Cedar

- Birch

- Port Orford cedar

- « Previous Page

- 1

- …

- 40

- 41

- 42

- 43

- 44

- …

- 95

- Next Page »