Slatwall has taken a whole new turn as patented SingCore makes lightweight slatwall available that is very strong as modular slatwall components to create the most comprehensive lightweight slat wall system that can be easily interlocked and used as trade show displays.

Affordable Slatwall

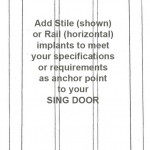

The ability of SingCore to offer standard-sized slatwall components makes Sing slatwall the most affordable and durable thermally-fused laminate (TFL) slat wall system (which is also easy to attach and remove your vinyl graphics, if you so desire) available with interlocking lightweight slatwall panels which do not require a base wall or stick framed wall to attach the slat wall to.

Slatwall Panels

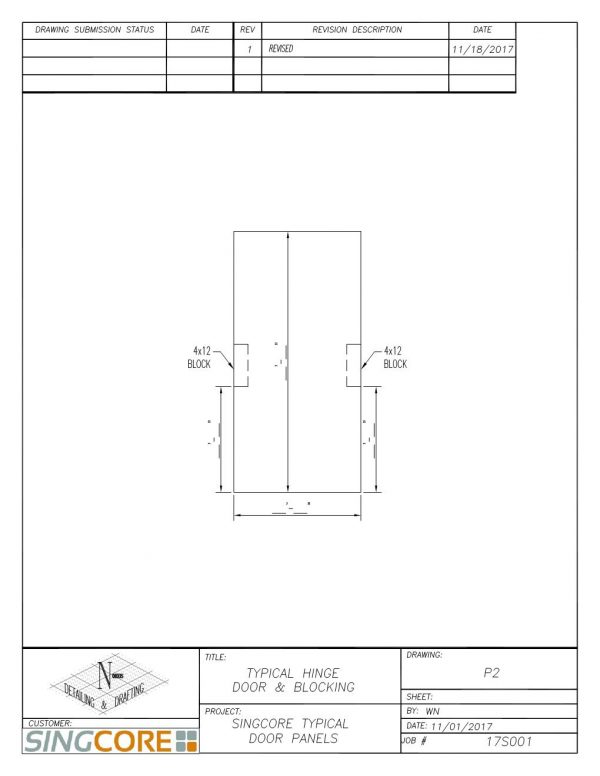

Patented Sing slatwall panels are affordable in standard sizes, such as retail slatwall panels at 47.5 x 95.5 inches and modular slatwall panels used as trade show displays in two sizes: 90 x 36 and 90 x 22 inches, each slatwall panel is 2 inches thick and features slatwall slots every 6 inches.

Modular Slatwall Panels

Your standard sing slatwall panels may be configured and reconfigured in any way you so desire. Additional slatwall panel components in standard sizes and connection standards can be purchased at any time to expand or radically change your slatwall system design. Sing reusable slatwall is lightweight and flat packs for easy storage in between uses, if for temporary purposes. In the case of slatwall trade show displays, your entire slatwall display system can be easily flat packed for shipment to the next trade show or back home for storage until next year.

Lightweight High Strength Metal-look Slatwall

Our new alternative for making lightweight metal-looking metal slatwall panels incorporates the use of decorative HPL surfaces, from manufacturers like Masonite and Formica. Following are photo examples of just some of the metal-look lightweight high strength slatwall surface materials available.

- Aluminum Stainless Slatwall

- Brushed Aluminum Slatwall

- Brushed Stainless Slatwall

- Brasstoned Aluminum Slatwall

- Mirror Aluminum Slatwall

- Polished Aluminum Slatwall

Examples include Aluminum Stainless Slatwall, Brushed Aluminum Slatwall, Brushed Stainless Slatwall, Aluminum Footplate Slatwall, Brasstoned Aluminum Slatwall, Mirrored Aluminum Slatwall, Polished Aluminum Slatwall, Satin Aluminum Slatwall, and Solid Metal Skatwall made with HPL that looks like real metal panels at a fraction of the cost. This is the economical approach to metal slatwall panels. If you don’t see what you are looking for (these are the most popular metal-look slatwall panels), just ask us.

Slatwall Trade Show Booth

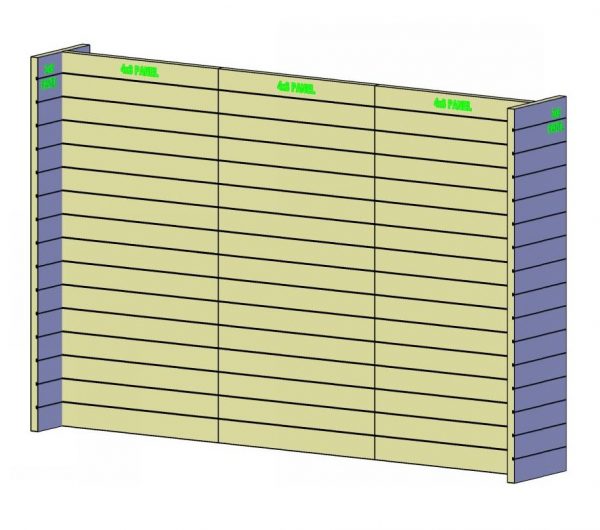

Standard Slatwall Modular 10×10 Booth Complete

Add our standard 10×10 Modular Trade Show Booth with one click on the add to cart button. Complete 10 x 10 trade show booth includes: 9 – 36 inch, 3 – 22 inch, 9 I connectors, 2 L connectors and 2 O connectors to complete the entire kit with all cam lock trade show panels. These patented display panels measure 22 to 36 inches wide. They are lightweight and easy to handle and can be easily assembled by 1 or 2 laypersons.

Sing slatwall trade show displays are created by connecting individual double-sided lightweight slatwall panels in your choice of 36 inches or 22 inches together with our 2 inch connection standard. Keep this in mind when designing your trade show displays.

We do not help with the design, but offer the components to you on an a la carte basis. Simply select the number of 36 inch slatwall panels, 22 inch slatwall panels and 2 inch connection standards you need to see your trade show booth design come to life. Slatwall panel connection standards are available in several configurations to accommodate your slatwall trade show booth design.

The following are modular slatwall panels and trade show booth components for your trade show displays:

Individual Components

Create your own modular trade show display of any size, type or style by adding the individual components to your shopping cart.

Standard Slatwall Trade Show Panel “A”

![]() They key component for designing and building your trade show display walls is our “A” lightweight slatwall trade show panels. These patented display panels measure 36 inches wide. They are lightweight and easy to handle.

They key component for designing and building your trade show display walls is our “A” lightweight slatwall trade show panels. These patented display panels measure 36 inches wide. They are lightweight and easy to handle.

Standard Slatwall Trade Show Panel “B”

![]() Our alternatively-sized component for your custom trade show display walls consists of our “B” lightweight slatwall trade show panels. These patented display panels measure 22 inches wide.

Our alternatively-sized component for your custom trade show display walls consists of our “B” lightweight slatwall trade show panels. These patented display panels measure 22 inches wide.

Standard Sing Trade Show Display “I”

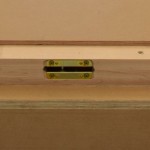

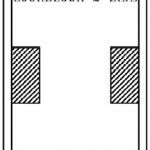

![]() The Sing tradeshow display I is the key block component with two receptacles for attaching cam-locks for connecting two standard trade show panels side-by-side. The standard dimensions of this corner connector is 2 inches by 2 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining.

The Sing tradeshow display I is the key block component with two receptacles for attaching cam-locks for connecting two standard trade show panels side-by-side. The standard dimensions of this corner connector is 2 inches by 2 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining.

Standard Sing Trade Show Display “L”

![]() The Sing tradeshow display L is the key corner block component with two receptacles for attaching cam-locks for a 90 degree corner connection of two standard trade show panels. The standard dimensions of this corner connector is 2 inches by 2 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining.

The Sing tradeshow display L is the key corner block component with two receptacles for attaching cam-locks for a 90 degree corner connection of two standard trade show panels. The standard dimensions of this corner connector is 2 inches by 2 inches and can be used as booth corners or in combination with trade show panels to create free-standing offices or storage compartments. All Sing trade show display components feature cam lock connectors for quick, easy and secure fastening and joining.

Standard Sing Trade Show Display “T”

![]() The Sing tradeshow display T is the key corner block component with three receptacles for attaching cam-lock sets for a 90 degree corner connection of three standard trade show panels. As you determine your design keep in mind the dimensions as it measures 2 inches by 2 inches.

The Sing tradeshow display T is the key corner block component with three receptacles for attaching cam-lock sets for a 90 degree corner connection of three standard trade show panels. As you determine your design keep in mind the dimensions as it measures 2 inches by 2 inches.

Standard Sing Trade Show Display “X”

![]() The Sing tradeshow display X is the key corner block component with four receptacles for attaching cam-lock sets for a 90 degree corner connection of three standard trade show panels. As you determine your design keep in mind the dimensions as it measures 2 inches by 2 inches.

The Sing tradeshow display X is the key corner block component with four receptacles for attaching cam-lock sets for a 90 degree corner connection of three standard trade show panels. As you determine your design keep in mind the dimensions as it measures 2 inches by 2 inches.

Standard Sing Trade Show Display “O”

![]() The Sing tradeshow display O is the key end cap block component with one single receptacle for attaching cam-lock sets to finish the otherwise exposed ends of modular trade show panels. As you determine your design keep in mind the dimensions as it measures 2 inches by 2 inches.

The Sing tradeshow display O is the key end cap block component with one single receptacle for attaching cam-lock sets to finish the otherwise exposed ends of modular trade show panels. As you determine your design keep in mind the dimensions as it measures 2 inches by 2 inches.

Retail Slatwall

Our retail slatwall panels are larger to accommodate the most versatile use as they can be free standing slatwall walls, replacing expensive slot wall or slatted wall systems. Sing they are available in a standalone 2-inch thick standard sized 4×8 slatwall panel (finished size 47.5 x 95.5 inches) they can be cut on site to fit any retail slatwall requirements your establishment may desire. Retail Slatwall 4×8 (47.5 x 95.5 in.)

Retail slatwall panels feature slatwall on both sides of the panel. If slatwall is no needed on one side of the slatwall panel, simply disregard its existence. Or, alternatively you could have your retail slatwall panels custom manufactured to different size specifications, or with slatwall only on one side of the slatwall panels at an additional cost.

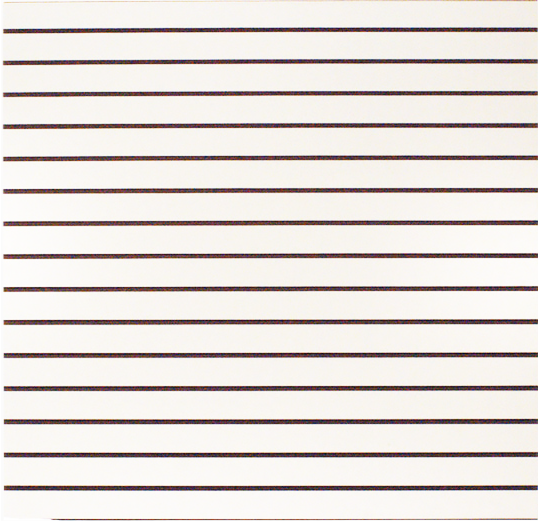

Slatwall Colors

Sing slatwall panels are available in many colors. Standard slatwall panels are available in your choice of White slatwall panels or Hard Rock Maple slatwall panels. Other colors are available, but will require additional time for delivery due to custom manufacture.

No waiting on standard slatwall panels in either White or Hard Rock Maple, as these items are regularly stocked for faster delivery expectations.

Sing Slat Wall Panels

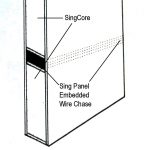

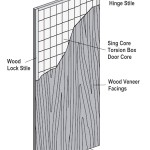

Sing slat wall panels weight a fraction of the weight of stick built slat wall panels and resist deflection and warping over long spans and for the sophisticated high end user may be available in premium grade which would include our 50 year warp-free guarantee.

Custom Slatwall Panels

Custom lightweight slatwall may be manufactured individually at additional cost and turnaround time. Available for custom manufacture in any available flat building material, such as fiberglass slatwall (FRP slatwall), glass slatwall, HPL slatwall, Kevlar slatwall, Lexan slatwall, LVL slatwall, MDF slatwall, PVC slatwall and/or wood slatwall.

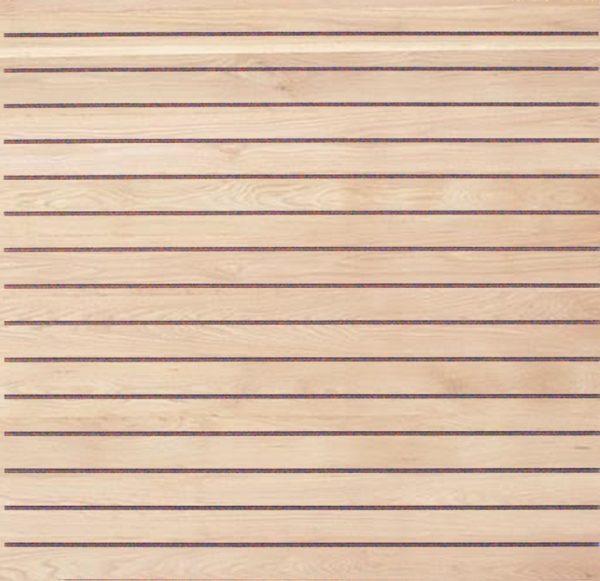

Organic Wood Slatwall Panels

Natural wood slatwall is available in any available organic wood species as surface material, such as Birch wood slatwall, Oak wood slatwall, Cedar wood slatwall, Knotty pine wood slatwall, Walnut wood slatwall, Alder wood slatwall, Mahoghany wood slatwall, Maple wood slatwall, Cherry wood slatwall and Teak wood slatwall among other species and varieties.

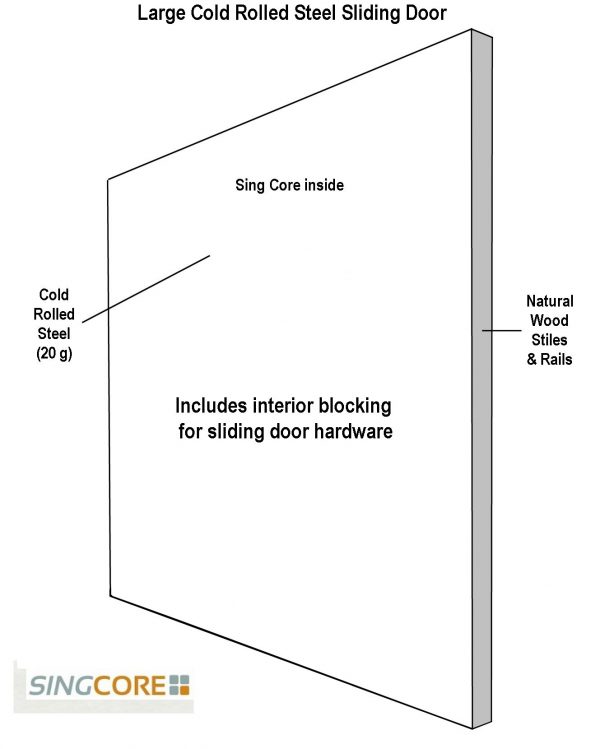

Metal Slatwall

Among our custom lightweight slatwall panels, metal slatwall is a high-end (expensive) exquisite option available in any type of metal, such as aluminum slatwall, cold rolled steel slatwall, copper slatwall, diamond plate steel slatwall, galvanized steel slatwall, hot rolled steel slatwall or stainless steel slatwall. Basically any type of metal slatwall can be custom manufactured to meet your specifications. Prices and delivery times may vary according to the metal slatwall material specified.

- Birch Wood Grain Slatwall

- Freestanding FRP Slatwall

- Vertical Wood Grain Slatwall

- Horizontal Wood Grain Slatwall

- Butcher Block Slatwall

- Wood Stave Slatwall

- Natural Wood Slatwall

- Cherry Butcher Block Slatwall

- Chalkboard Slatwall

- Galvanized Slatwall

- Aluminum Slatwall