There’s no doubt about the growth in the pivot door market. Just a few years ago pivot doors were the exception to the rule, today more and more people want to make an impact statement by featuring a pivot front door, and nothing packs more curb appeal than large pivot doors, leaving an everlasting impression. In fact, the bigger the pivot door, the better.

You know what having a large pivot door means? You got it = large prices, on everything. Everything is more expensive when you’re dealing with a large pivot door. Think about it… Large pivot doors are large and thick, that means they’re cumbersome and they’re hard to manage on the job site, sometimes requiring extra heavy equipment just to move them about the site. Of course, they are heavy, which means transportation is going to be expensive, as well as the heavy duty pivot door hinges (also expensive) because the weight of the large pivot door determines which hardware is needed to support the extra weight.

The extra weight can be a problem if it is being used regularly, causing extra strain on both the hardware and the structure itself; resulting in costly maintenance and repairs to the pivot door and the structure as well over time.

But wait, there’s more: Since everyone wants to have a large pivot front door that means one side of the door faces the structure’s interior while the other side is exposed to the elements, and you know what that means? You got that right: Warped doors! When is a door not a door? When it’s so warped you can’t secure it. There you go = more costly repairs.

What If…

What if one type of large pivot door could overcome all the hassles associated with other large pivot doors. I mean, if the laws of physics could be suspended for a moment, and you could have a large pivot door any way that you wanted it, what would that large pivot door look like?

Pivot Door Size

To start, size would not be an issue. You could have any size large pivot door in any thickness you wanted, without having to make a zillion calls to find anyone who would undertake such a challenge.

Pivot Door Options

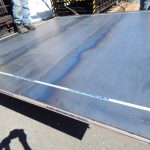

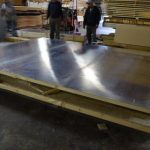

You would want to be able to specify any material to have the large pivot door manufactured out of, and it wouldn’t matter if it was concrete, natural and/or exotic wood, including any metal from aluminum to hot rolled steel, or any other available flat building material. You could have whatever you wanted.

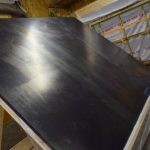

Lightweight Pivot Doors

If you could have it any way you wanted it, you would have this large pivot door weigh a fraction of any other pivot door, so that you could reduce transportation, installation and hardware costs at the get-go, as well as having less expense over time, because the lighter weight means less stress and strain on hardware and structure, and less maintenance costs.

High Strength Pivot Doors

If the large pivot door is going to be lightweight, we do not want it to be wimpy. I want to know my family is safe a secure from forced entry, and if someone tries to kick in the pivot door, I want them to break their leg. And if I accidentally drive a pair of forklift forks through it, I want to know that it’s strong enough to take the impact without compromising the pivot door, and can easily be repaired (without having to remove the large pivot door).

Warp-free Pivot Doors

Might as well throw in the idea of having a large pivot door with superior warp resistance; how warp resistant would you want? Okay, let’s say it. We want a door that does not warp, period, even if it is used as an exterior-facing pivot front door.

Pivot Door Insulation

Just for fun, we might like to throw in the idea of having a large pivot door that is well insulated to provide more safety and security from sound deadening and energy savings to superior climate control.

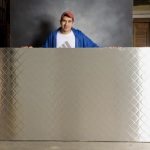

Customizable Pivot Doors

I’d want to be able to customize the large pivot door any way I wanted to, including custom lite cutouts in any shape and style I wanted (not being limited to having to pick from a few options). I want it the way I want it. Can we do that?

You Can Have It All

You can have all this and more! What? Surely you jest. Nope, I am being totally honest with you. You can have everything you could imagine, like unlimited size restrictions for your large pivot doors, made out of any flat building material available, weighing in at a fraction the weight of other solid core pivot doors, yet stronger than steel pound for pound and guaranteed not to warp, bend, twist of fail structurally for a full 50 years.

Oh, and you can have all the insulation you want for sound dampening and saving energy, as well as custom lite cutouts, where you want, in any shape you like.

Now, that is the perfect large pivot door

The most exciting thing about all this, is that it is not just a fantasy, but Sing Core does actually help the best millworks and door companies to supply their customers with the very best large pivot doors available in the world today.

How is it possible?

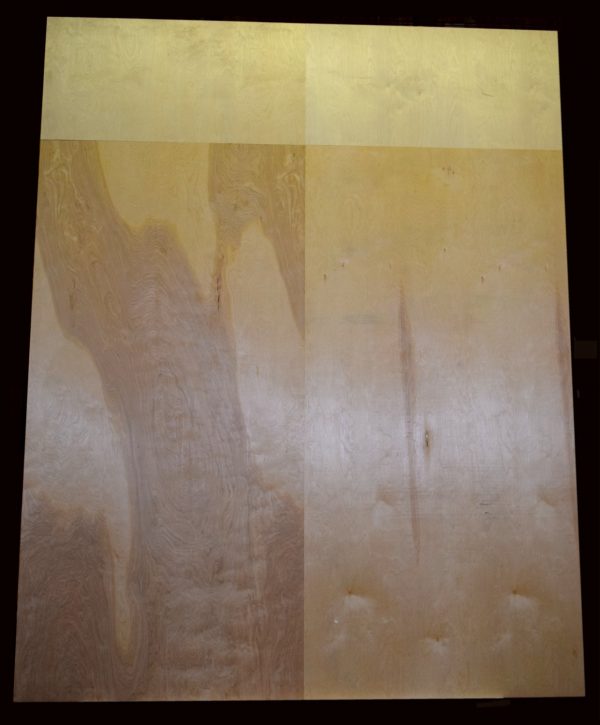

The large pivot door technology was birthed from the imagination of inventor, Peter Sing, whose next generation reinforced torsion box design enabled him to be able to accomplish all these feats, outperforming other aerospace-inspired lightweight core materials (rated at 10 to 110 PSI), while Sing’s core clocks in at 660+ PSI. And if you want a high precision pivot door (which is why you see Sing’s products featured from beneath the sea [US Navy] to outer space [NASA]), very few materials can be made so high precision (+/- .006 in.).

With all these features and benefits, who wouldn’t want a large pivot door with Sing Core inside?

How Can I Get A Sing Large Pivot Door?

Here’s the tricky part, and I will lend you a hand, hopefully making it easy for you to get a Sing large pivot door. It’s tricky because Sing Core does not make the doors themselves, they only supply the millworks and custom pivot door manufacturers with the raw materials they need to create these large pivot doors that are anything short of amazing. And that’s the secret.

All you have to do is to go to your favorite local millwork or custom pivot door manufacturer and tell them what kind of pivot door you want, and be sure to say, “I want Sing Core inside.” It’s as easy as that. While Sing Core does not build or finish doors, they do supply the best door makers with the best material available to create the best pivot doors ever manufactured in the United States of America. And, yes, Sing Core is proudly made in the USA.

- Oak