Basically, a Sing Panel is Sing Core sandwiched between two skins with solid wood borders on all edges.

Sing Core Comparisons Based on 2″ x 2″ Grids

|

Sing Panel |

Foam |

Aluminum |

Balsawood |

Nomex |

Plastic |

Cardboard |

| Insulation |

✓ |

✓ |

x |

x |

x |

x |

x |

| Sound Deadening |

✓ |

✓ |

x |

x |

x |

x |

x |

| Lightweight |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

x |

| Strength |

✓ |

x |

✓ |

✓ |

✓ |

x |

x |

| Solid |

✓ |

✓ |

x |

✓ |

x |

x |

x |

| Eco-friendly |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Renewable |

✓ |

x |

x |

✓ |

x |

x |

✓ |

| Oversize |

✓ |

x |

x |

x |

x |

x |

x |

| Dimensionally Stable |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

✓ |

| Affordable |

✓ |

x |

x |

x |

x |

x |

✓ |

| Waterproof Upgrade? |

✓ |

✓ |

✓ |

x |

✓ |

✓ |

x |

| Fire Retardant Upgrade? |

✓ |

✓ |

✓ |

✓ |

✓ |

x |

✓ |

| Bullet-proof Upgrade |

✓ |

✓ |

x |

x |

x |

x |

x |

| Thickness Available |

✓ |

x |

x |

x |

x |

x |

x |

| Skin Options |

✓ |

x |

x |

x |

x |

x |

x |

| Easy to Machine |

✓ |

x |

x |

x |

x |

x |

x |

| Fast Turnaround |

✓ |

x |

x |

x |

x |

x |

x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

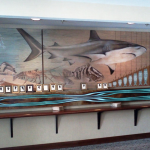

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, the Sing Core fire retardant door is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength)

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly.

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core exceeds AWI standards for flatness and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due temperature and moisture change.

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Waterproof upgrade: Sing Core is available in waterproof upgrade, to accommodate your specific water resistant requirements.

Fire retardant upgrade: When used in fire retardant applications, Sing Core is the lightweight, super-strong, eco-friendly alternative.

Bullet-proof upgrade: In high-security end products, most cores used in bullet-proof applications are heavy in weight, causing strain on the infrastructure, unlike Sing Core.

Thickness available: Almost any thickness

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

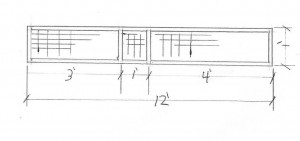

Multiple Sing Panels can be joined together to achieve the results you desire, including on-site multi-panel projects. large doors or trade show booths.

The most popular gift for university students, this year, is the standing computer desk.

The most popular gift for university students, this year, is the standing computer desk.

What can you expect from Sing Core?

What can you expect from Sing Core?