- Easy to install wood flooring

Hardwood On-Demand

In an effort to share the latest technology and advancements in wood production and stock, Sing Core is releasing their Sing Hardwood On-Demand system to small work shops and large millworkers. Sing Core revolutionizes the wood working industry by re-introductcing torsion-box technology (click here for torsion box info). Craftsmen have been using torsion box for centuries, but it takes a skilled craftsman two days to create a table… Sing Core provides craftmen with the torsion box structure pre-built. Doing so allows you to make 10 times more tables in a single day.It’s taken hundreds of years to come up with a superior torsion box process that is extremely effiective, yet does not burden the production process. For a limited time and as little as $100, you can have this system to experiment with in your shop so that you can experience the lightweight, super-strength of Sing Core, and have more control over your inventory giving you the ability to create your own Sing Hardwood On-Demand.

Applications include:

- Wood flooring

- Wood Ceiling

- Wood Siding

- Wood Scaffolding

- Shelving

- Stairs

- Staircases

- Wood plank walls

- Butcher Block

The patented raw Sing Core material is provided to you in bulk. Shipping costs are minimal due to the raw material being so lightweight. You store the bulk Sing Core material and assemble your own Sing Core Hardwood

Sing Core Panels

Standard stock Sing Sandwich panels  Measurements: 4 ft. x 8 ft. x 3/4-to-1.56 inch thickness (other sizes available).

Measurements: 4 ft. x 8 ft. x 3/4-to-1.56 inch thickness (other sizes available).

Sing Sandwich Application: Cur or rip Sing Sandwich as solid lumber core use it as substrate to glue plywood or wood stave to make hardwood lumber.

Sing Sandwich Advantage: Sing Sandwich features our patented torsion box design, it is true flat, lightweight, dimensionally stable. Hardwood made of Sing Sandwich is the strongest, lightweight hardwood. It is more affordable than most expensive hardwood, you are able to create your own Sing Hardwood with basic woodworking tools, like:

- Band saw

- Sanding machine

- Cold glue press

You cold glue press could be made of Sing Timber Plank which is lightweight, true flat and super strong to press hardwood wood staves over on top of Sing Sandwich. Click here for more information on the Sing Sandwich material.

Of course we can assist you with any step of the process along the way to making your own Sing Hardwood stock. Some options include:

1. SING CORE BLOCK

(Only available under license)

2. SING CORE SLICE

(Sing Core Block pre-sliced and sanded to your specifications)

3. SING CORE SHEETS

(Sing Core Sheets are pre-cut to length, width and thickness to your specifications)

4. SING CORE WITH SOLID WOOD EDGE

(Sing Core pre-asembled with solid wood edges along along length exteriors)

5. SING CORE PLANK

(Sing Core with Solid Wood Edges and your choice of skin)

Also available…

Sing Timber Block

Sing Timber Block Measurement: 12 inch x 12 inc x 8 ft

Sing Timber comes complete with solid wood planks on both sides of the Sing core.

Sing Timber comes complete with solid wood planks on both sides of the Sing core.

Sing Timber consists of Sing Core Block with two pieces of slab added to each side 1.5 inch x 10 inch x 8 ft.

The purpose of Sing Timber is to create solid wood edges on both sides of Sing Core Block after slicing to desired thickness. All you need is to add skins on top and bottom as needed. Resulting in (for instance) a shelf of Sing Plank ready to add wood staves, wood veneer or any other type of exterior facing skins.

You could make your own Sing Timber by purchasing a Sing Core Block, then saw to your desired width, add solid wood to form any width, and your’re doo to go.

Sing Wood Substrate

Sing Core is also available as a torsion-box substrate (honeycomb wood) to be used as a substrate for any wood (or other external material) substrate.

This is Sing Core with plywood faces for easy bonding of any other hardwood face material with in-house carpenter glue.

Is also available in widths exceeding 12 inches as “Sing Panels” (see below)

Sing Plank

Sing Planks have no hardwood only plywood skin

Advantage:

You do not have to wait your hardwood supplier ship to you over night from hundreds or thousands miles away, giving you inventory on-demand. All you need is stock to stock some Sing Core Block and you can create any building materials that you need, to your specific dimensions on-the-fly.

Q: Are there any other methods to build hardwood from substrate?

A: There are many type of substrate used as a base to add hardwood staves to create hardwood. It is common for veneer and/or staves to be glued on top or wrapped around with hardwood to make hardwood, but it is very heavy and sometimes unstable, creating movement. The most common substrate used is particle board, followed by MDF, plywood and LVL.

The ideal substrate is honeycomb or lightweight foam to use as substrate, but none of those lightweight materials are able to achieve the strength of Sing Core which when tested in University of Washington reached 660 PSI. Most common honeycombs (such as aluminum honeycomb core, plastic core, and paper core) and foam used in aviation industry are approximately 100 PSI, but the cost is more than 10 times more in comparison to Sing Core, and much heavier than Sing Core. This is the reason Sing Core is the primary choice for high end mill work in USA.

With some basic shop tools, you are able to build your own Sing Planks or even Sing Wood at any thickness or width.

Sing Hardwood

Advantage Sing Hardwood:

With Sing timber to saw any thickness, width to build your own Sing Hardwood. you can make any wood species, without having to inventory hundreds of hardwood planks, slabs, beams, boards, etc…

2 User Friendly.

Lightweight, strong, true flat, easy to machine to wood plank,wood beam, wood post , shelving, stair treads…

3 Stronger Than Steel

Sing Core is stronger than steel and wood lbs for lbs. When tested by the University of Washington, Sing Core had reached beyound 660 PSI. Average foam core or honeycomb core used in aircraft are approximately 100 PSI, yet cost more than 10 times the cost of Sing Core. High strength, without high cost.

You can make your own Sing Hardwood at your location by using Sing Core Block.

Sing Panels

Advantages of Sing Panels:

Sing panels can be used to replace many building materials, especially when compared to other materials that are heavy. Reminding us that the rules of construction philosophy have changed:

Sing panels can be used to replace many building materials, especially when compared to other materials that are heavy. Reminding us that the rules of construction philosophy have changed:

“Heavy does not mean strong.”

and

“Lightweight does not mean weak.”

Whether you’re replacing plywood, other panels, exterior cladding, moveable wall systems, exterior walls, floors, ceilings, ect… No other building material compares to Sing Core panels.

Sing Panels have a plywood exterior for easy bonding of any other wood material to the Sing Core material.

Armed with Sing Core Block at your location, you could manufacture your own Sing Panels.

Call Sing Core at 360-495-3577

to get your Sing Sandwich panels today and SAVE

Specialty Panels

Specialty Panels

Sing Core offers a wide range of sizes.

Getting a quote for your specialty product, is easy, thanks to our simple online order system.

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order.

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantitiy and wholesale inquiries are encouraged. Feel free to contact us for more information.

How to Cold-press Sing Panel

Using Sing Sandwich Substrate, it’s easy to build your own Sing Panels on demand.

Using Sing Sandwich Substrate, it’s easy to build your own Sing Panels on demand.

This is the most popular in-house technology used by craftsmen and millworks.

You might have never known how easy it is to build your Sing Panels using this cold-press drop-in method.

How Easy Is It?

This is how simple it is to for you to use our substrate.

All you have to do is to coat the underside of your bottom skin with regular carpenter glue…

Place your wood edges atop the glued-side of the skin…

Then fill the void with Sing Sandwich substrate pieces until full.

Place glued top skin onto your completed work…

Finally cold-press until dry.

It’s that easy: Congratulations; you just made your own Sing Panel.

Details, photos and instructions compliments of Lightweight University.

Sing Post and Beam

Sing Post and Beam – A Smarter Way to Build

Sing Post and Beam changes how structures are built.

Traditional beams are heavy. However, Sing Post and Beam is lightweight.

Solid wood warps. In contrast, Sing Post and Beam stays straight.

Because of patented Sing Core technology, Sing Post and Beam delivers strength, stability, and ease of construction in one system.

How Sing Post and Beam Structures Are Built

The Sing Post and Beam system follows a simple process. As a result, construction becomes faster, safer, and more precise.

Step 1 — We Manufacture the Sing Post and Beam

First, we build every Sing Post and Beam post using our patented core.

Inside each Sing Post and Beam is:

-

A vertical grain veneer torsion box

-

Structural skins

-

Lightweight EPS foam

-

Solid wood edging

Because of this structure, Sing Post and Beam products act like endless I-beams. Therefore, weight spreads evenly. As a result, the beam resists sagging.

Traditional posts fight gravity. However, Sing Post and Beam works with engineering.

So the benefits are clear:

-

Straight and warp-free

-

Strong yet lightweight

-

Resistant to weather

-

Stable through temperature changes

Most importantly, Sing Post and Beam posts remain dimensionally stable over time.

Lightweight Sing Post and Beam Structure

Sing Post and Beam can weigh as little as 30% of traditional materials.

Therefore, handling is easier.

Also, installation is faster.

Step 2 — The Roof Structure Is Built on the Ground

Next, we assemble the roof frame using Sing Post and Beam beams.

Because the beams are lightweight, workers can handle them easily.

Also, because they are torsion box engineered, they stay flat.

Therefore, the roof structure goes together quickly.

Traditional beams twist. However, Sing Post and Beam stays true flat within .007 inches.

As a result, alignment is easier. In addition, fewer corrections are needed later.

So, we build the entire Sing Post and Beam roof system safely on the ground.

Step 3 — Forklifts Lift the Sing Post and Beam Roof

Then, the full roof structure is lifted.

Because Sing Post and Beam is lightweight, forklifts can raise the entire assembly.

In contrast, traditional materials would require complex lifting plans.

Furthermore, torsion box rigidity keeps the frame stable during lifting.

Therefore, placement becomes smooth and controlled.

Step 4 — The Roof Lands on Four Sing Post and Beam Supports

Now, the structure comes together.

The lifted roof is set onto four primary Sing Post and Beam posts.

Because of long-span strength, fewer supports are needed.

As a result, open interior space increases.

Moreover, load spreads across the engineered core.

Therefore, deflection stays low.

Also, geometry remains stable.

No settling. No twisting. Or warping.

Step 5 — Walls Are Added to Complete the Sing Post and Beam Structure

After the Sing Post and Beam frame is in place, walls are added.

Since the structure carries the load, walls are simply enclosure.

Therefore, design flexibility increases.

Sing Post and Beam systems are ideal for:

-

ADUs

-

Workshops

-

Garages

-

Studios

-

Modular structures

-

Additional buildings

- Why Sing Post and Beam Performs Better

Sing Post and Beam Dimensional Stability

Solid wood moves. However, Sing Post and Beam stays straight.

Because of torsion box engineering, movement is minimal.

Sing Post and Beam with Built-In Insulation

Sing Post and Beam includes insulation values from R 3.5 to R 6.5.

In contrast, solid wood provides far less.

Precision

Sing Post and Beam remains flatter than solid lumber.

Therefore, fit and finish improve.

Weather Resistance

Additionally, Sing Post and Beam resists rot and moisture.

So long-term performance improves.

Engineering and Testing Behind Sing Post and Beam

Sing Post and Beam was developed through testing.

Load testing confirmed strength.

Deflection testing confirmed stiffness.

Environmental testing confirmed stability.

Because of this development, Sing Post and Beam solves major building problems:

-

Excess weight

-

Warping

-

Material movement

-

Structural inefficiency

The Advantage of Sing Post and Beam

Sing Post and Beam changes workflow.

First, build on the ground.

Next, lift once.

Then, set in place.

Finally, add walls.

Faster. Safer. Lighter. Stronger.

That is why Sing Post and Beam is redefining structural construction.

*** GET AN ESTIMATE TODAY!!! ***

Ready to see what your project would cost? You can get a fast, personalized quote for your Sing Post and Beam structure directly from the source. Simply visit the Sing Core estimate page to share your project details, sizes, and specifications. From ADUs to large-span structures, the team will review your needs and provide pricing based on your exact design. Start here to request your estimate: https://singcore.com/pricing-3/get-an-estimate

See more of what Sing Core has to offer

See how Sing Core technology powers oversized, lightweight, warp-free doors at https://10ftdoors.com/.

2 x 12

Introducing the new staple of lumber and hardwood mills, factories and yards:

Sing 2 x 12 Wood Plank

The Sing 2 x 12 is the most versatile eco-friendly hardwood lumber replacement in the world. Now available in Bamboo-style format.

The Sing 2 x 12 is the most versatile eco-friendly hardwood lumber replacement in the world. Now available in Bamboo-style format.

No other wood 2 x 12 can match the performance features of Sing’s 2×12, like:

- Lightweight

- Straight and true

- Twist, cup and warp resistant

- Super strong (stronger than steel lb for lb)

- Eco-friendly

Sing 2x12s are Flat, Straight and True

Each Sing 2×12 is extremely flat, with no twisting or cracking, unlike solid wood. Sing 2x12s can be used just like any other conventional hardwood, or softwood to build furniture, used as building material for boats, signs, planks, trade show displays, etc…

Sing 2x12s require no tongue-and-groove. Why? Because Sing 2x12s are straight and true, will not warp or twist over time. Therefore, assembling multiple lengths of Sing 2x12s is easy, painless and requires no tongue-and-groove to act as anti-warp control. Sing 2x12s can be joined edge-to-edge with standard carpenter glue, leaving a perfect seam every time, that will last the test of time.

Click here to see our Sing 2x12s in action in our 2×12 Photo Gallery.

Sing 2x12s are Dimensionally Stable

Lumber is unstable. You know what it’s like to try to find a straight piece of lumber… Then, once you use that piece of standard lumber, who’s to say how straight it will be in a year, or ten years? Tounge-and-groove was invented in an attempt to try to deal with the instability of commercially available lumber.

The unparalleled versatility makes Sing Core’s 2×12 the most amazing product to hit the woodworking industry since… the saw.

Sing 2 x 12 plank by itself will be idea to use as

Sing 2 x 12 plank by itself will be idea to use as

- substrate

- use as shelf

- stair treads

Sing plank can by saw to narrow plank to use as

- crown molding

- base molding

- trims

It has solid wood edge for edge glue to form any width and length to build

- large table top

- bench

- furniture part

- lightweight RV panel(s)

- plank door (or add veneer to build high-end wood grain door)

- raised floor

- wide plank floor

- wall

- roofing system

Take Your 2×12 to the Next Level

By adding aluminum on all sides than you have the perfect

- outdoor furniture

- trestle

- outdoor decking

- railing

Besides aluminum, the versatile 2x12s could be bonded to plastic, FRP, cement board, hardwood, metal… all can be options to use as external skins to create a stronger, lightweight, or all-weather material for different applications, including ceiling clouds.

Sing 2×12 Lumber, Metal and much more….

Sing 2×12 Lumber, Metal and much more….

The Sing 2×12 is not any type of soft wood or hardwood that you’ve ever known before; it is a basic material to build almost everything we use in our daily life.

1 Sing 2 x 12 x 8 foot panel

Why have we developed the Sing 2 x 12 x 8 foot Sing Plank?

- The Sing 2×12 is a superior match having the greatest amount of flexibility in diverse applications.

- Sing 2x12s can be produced in train load quantities. It has all the features of Sing Panels but at a lower cost. Sing 2 x 12 planks could use as substrate. Sing 2x12s can be edge-glued or end-glued to join and create any length or width. It is easy to append with any skin to accommodate any thickness. It is the most lightweight (1.5 lbs. per linear ft.), true flat and strongest insulated lumber ever invented.

Click here to see our Sing 2x12s in action in our 2×12 Photo Gallery.

2 Bamboo-style Sing 2×12 plank.

Why have we developed the Bamboo-style Sing 2 x 12 x 12 inch?

The only drawback when cutting 2 x 12 Sing Planks is exposing a portion of the Sing Core. When cutting the Sing 2×12 you need to remove a portion of the Sing Core and add insert a solid edge to end cap the exposed end. We have developed the solution by adding solid wood implants to create a Sing 2 x 12 like bamboo, providing cut points which will not expose Sing Core. It will have solid wood pre-installed at end of the Sing Panel cut point.

Due to the feedback of woodworkers who have heavy production schedules, we developed a new and improved Sing 2×12, that we call the Bamboo 2×12.

In much the same way that bamboo’s strength-cut-points occur naturally, Sing has scientifically redesigned the Sing 2×12 into its most prominent advancement, The Bamboo-style 2×12.

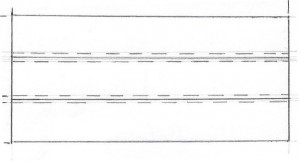

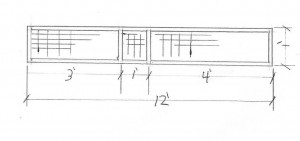

You can see in the drawing (above) that 2 bamboo-like nodes have been put in place in the Sing 2×12 interior in the center-foot-area.

You can see in the drawing (above) that 2 bamboo-like nodes have been put in place in the Sing 2×12 interior in the center-foot-area.

Cutting areas are precisely marked for your convenience. This allows for easy cross-cutting into lengths that are predetermined by the woodworking artist.

For instance, when cutting lengths of 1’, 3’, 4, 5’ or 8’ the nodes (or wood stiles) are pre-installed for convenient cross-cutting into these standard lengths.

Using the standard Sing 2×12, cutting an 8 foot length into two 4 foot lengths, would require the production team or woodworker to install wood styles at the cross-cut point, which may slow-down the production time.

Now, with the new and improved Bamboo-style 2×12, these challenges have been resolved, streamlining the production process

In the example (above) you can see how easy it is to edge-glue (using standard carpenter’s glue) Sing Bamboo 2x12s together into a large panel that could be used as a tabletop, counter, door, etc…

Question: If I need to build a door or table at 36 inch wide x 84 inch x 1.75 inch, what should I use Sing 2×12 plank or Sing Bamboo-style plank?

Answer: The Sing 2×12 Plank, because the Sing Bamboo-style 2×12 added cut-points would be superfluous (plus, the Sing 2×12 is less expensive).

Aesthetically, the Bamboo-style 2×12 and the Sing 2×12 look the same. If you require the Bamboo-style 2×12, you must specify when ordering.

- lightweight non warping honeycomb door

- Storage Shelves

- Any skin: HPL any size furniture components

- Dressers

Wood Stave

Woodstaves (a narrow length of wood “stave” with a slightly beveled edge) can be utilized to form the exterior of Sing Core. These can be used to replace other types of solid wood building materials.

Woodstaves (a narrow length of wood “stave” with a slightly beveled edge) can be utilized to form the exterior of Sing Core. These can be used to replace other types of solid wood building materials.

Standard wood stave exterior measures:

- 1/8”

Using Sing Core with wood staves is ecologically responsible doe to having the same appearance as solid wood by using fewer natural resources.

Other benefits include:

- Material is stronger than (steel) solid wood

- Lighter in weight than solid wood

- Remains straight and flat

- Rot, warp and twist resistant

Using Sing Core with wood staves reduces:

- Energy consumption

- Production costs

- Labor costs

- Shipping costs

- Maintenance

- Waste

Standard Hard Wood Stave Options

|

|

|

|

|

| MAPLE | CHERRY | OAK | VG FIR | WALNUT |

Other thicknesses of wood stave may be available upon request, in nearly any wood species.

See also: Sing solid wood stave doors

- « Previous Page

- 1

- …

- 75

- 76

- 77

- 78

- 79

- …

- 95

- Next Page »