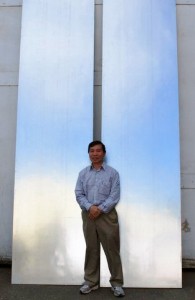

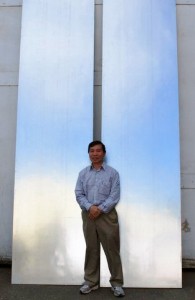

Sing Core 37 foot tall true flat doors

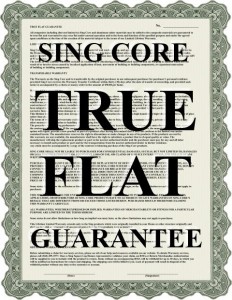

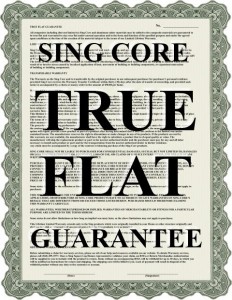

We guarantee that we are the only company in the world that can deliver true flat oversize doors that meet your expectations, if you desire a true flat solution, especially in the large, oversize door.

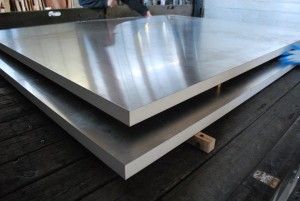

True flat technology is based on expertise in building any big door that can be guaranteed true flat and stay flat. This composite science includes the proper proportions of Sing Core, aluminum and/or other materials and bonding agents based on your requirements or specifications. In this way each big Sing door is a work of art.

One of the biggest challenges we see from designers and developers is that of the oversize door. Sure, anyone could make an oversize door, but can you make one that is true flat, maintaining structural integrity over long spans? That’s where Sing Core shines.

3 Types of Oversize Doors

There are three types of oversize door solutions, and in terms of meeting or exceeding the needs of the most high-end clients in the world. Our specialty is solving the problems associated with large oversize doors, while maintaining true flatness under extreme circumstances is unheard of, Sing Core helps us achieve the results that no one else can and remain lightweight and Eco-friendly, too.

1. Large Oversize Wood Door

The large oversize wood door has been a challenge for centuries because regardless of your expectations or requirements, the very nature of wood itself will provide additional challenges for both designer and the design. Not until the invention of Sing Core has there been a perfect solution for the issues associated with large oversize wood doors. See more information on Large Oversize Wood Doors.

2. Large Oversize Aluminum Door

For more extreme oversize solutions the Sing Aluminum Door is the better solution, especially when doors are expected to remain true flat under varying conditions. Aluminum has certain attributes that help us reach and exceed the requirements of the most demanding high-end clients. See more information on Large Oversize Aluminum Doors.

3. Large Oversize Wood/Aluminum Composite

The best solution for battling the issue of oversize without compromising the look, feel, beauty and elegance of solid wood is to call in the specialists at Sing Core to help design the perfect solution to your strictest concerns and requirements. See more information on Large Oversize Wood/Aluminum Composite.

4. Large Oversize FRP Composite Door

4. Large Oversize FRP Composite Door

If your large oversize door will be facing extreme weather conditions, temperature variations, or some other kind of added stress that might be above what would be considered normal exposure.

Every day someone finds the Sing Core solution.

For instance, when O.B. Williams needs a hundred oversize doors, that are guaranteed flat, who do they turn to? They call Sing Core to get the job done. Plus, you have all the advantages of patented Sing Core, with any appearance that you like i.e., aluminum or exotic wood grain finish…

In a hurry?

No problem. Sing Core can build your true-flat oversize doors for you in less than 3 days, even though our normal turnaround is 2 to 6 weeks.

Sing Core’s got your back.

We make you look good.

When your client demands only the best… You can confidently use Sing Core as your resource, because when it comes to oversize, true flat, nothing else even comes close.

Any look you desire…

Oversize Sing Core doors can achieve any exterior surface your customer desires, including (but not limited to) any wood species you customer desires, concrete, fiberglass, aluminum, stainless steel, fire-resistant Magnesium Oxide (MgO) Board, bullet-proof Kevlar, etc…

Oversize Sing Core doors can achieve any exterior surface your customer desires, including (but not limited to) any wood species you customer desires, concrete, fiberglass, aluminum, stainless steel, fire-resistant Magnesium Oxide (MgO) Board, bullet-proof Kevlar, etc…

How do we do it?

Oversize and true flat is a challenge that we take on every day. We know the perfect combination of patented sing core and aluminum, to maintain light weight, superior strength and true flat construction.

This is how we build sustainable, high-end, true flat doors consistently and guaranteed for ten years.

-

-

-

-

-

-

-

-

-

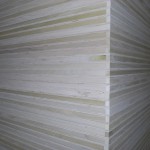

Large honeycomb sandwich door

-

-

-

Insulated Sing sandwich door

-

-

-

-

-

-

-

-

-

-

-

oversize lightweight high strength honeycomb door

-

-

large oversize lightweight high strength sing sandwich door

-

-

lightweight high strength large honeycomb door

-

-

Equipment enclosures

Equipment enclosures