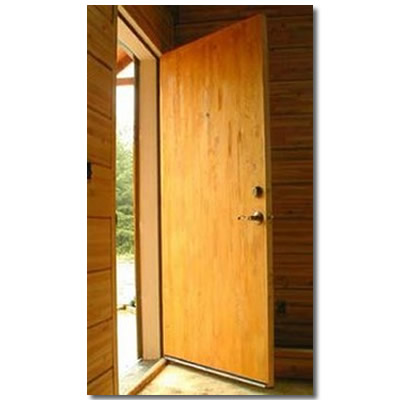

Sing Core has long been in the business of building the biggest warp-free doors in the world. And now you can learn how to build the biggest warp-free door as well. The first thing to note is that Sing Core does not build doors, even though Sing Core is credited and called out in architectural specifications as Sing Core door(s).

New Door or Replacement Door

Sing Core assists in the building of either New Doors, doors that have not existed before, or Replacement Doors, doors that are being replaced and may have to be replicated to maintain the appearance of the original door, such as in the case of participating in a historical restoration.

How to Build the Biggest Warp-free Door

Since Sing Core does not build doors, it is up to the architect to imagine what size the new door should be and of what materials the door should be made of. In the case of replacement doors, Sing Core is provided all the specs based on the original door to be either replaced or replicated.

The following steps are followed in making a door with Sing Core inside:

Step 1: Answer questions, and estimate

- What is the size (length, width, thickness) of the door?

- How will you be finishing the door

- What type of door hardware will be used (hinge, pivot, sliding, overhead, etc.)?

- What style of door (flush, architectural, plank, French, Dutch, etc.)?

- How and where will the door be used?

- Will this be an interior or exterior door?

- Are there other specifications (weight, insulation, sealing, etc.)?

Step 2: Re-evaluate and refer to Sing’s True Flat Team, if necessary

The True Flat team is available to help you provide your customer with a door that fits within their budget.

Sing Core and the True Flat team can suggest ways of changing some of the details of the panel, such as, reducing the height/width or choosing a more cost-effective skin.

Steps might need to be made to modify Sing’s composite hybrid solid substrate to accommodate the challenges that may not have been noted in the original details gathered in Step 1.

Step 3: Manufacture specified Sing Core

The specific Sing Core substrate core is then manufactured in Sing’s factory by skilled workers who have been manufacturing Sing’s cores for years using Sing’s patented and patent-pending technologies. Occasionally, a new challenge is recognized that the true Flat Team has never seen before, that is when Sing get to inventing again, and when a solution is achieved, this will likely lead to another patented solution.

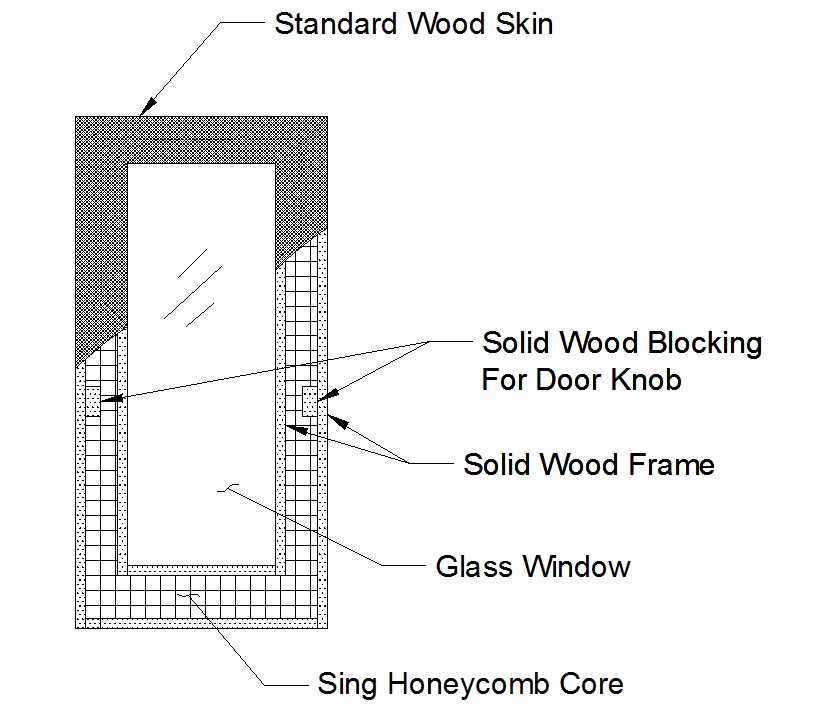

The core which is based on Sing’s insulated reinforced vertical grain torsion box core, may or may not be framed, and is sandwiched between two matching skins, ready to be used as door core.

If no other services are required, skip Step 4, and go directly to Step 5.

Step 4: Additional services

Some of the additional services that Sing’s factory may provide, include:

- Trimming

- Adding exterior skins

- Wood stave

- Veneer

- Cement board or concrete

- High Pressure Laminate (HPL)

- Fiberglass

- Formica

- Metal

- Aluminum

- Cold rolled steel

- Copper

- Galvanized steel

- Hot rolled steel

- Lead

- Stainless steel

- Impact/Bulletproof/Blast resistant materials

- Light cutouts, openings, for glass inserts

- Routing for architectural grooves

Step 5: Package and ship to millwork or door company

Step 6: Finishing