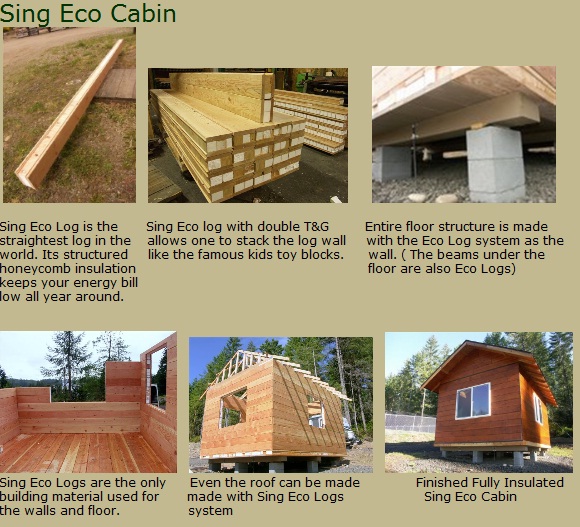

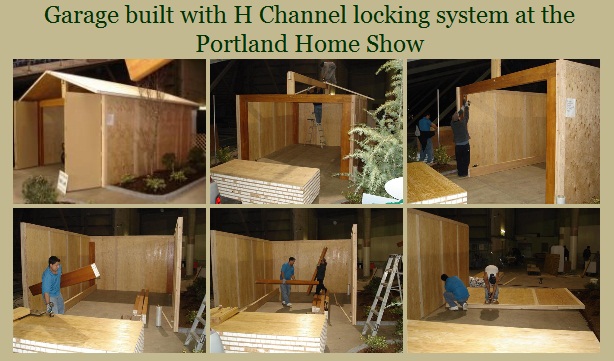

Sing Tiny House: How to build a Tiny House completely with Insulated Sing Honeycomb Panels

|

|

|

| Step Step 1

Lie Sing Honeycomb panels on top of a treated timber foundation frame and fasten with screws. |

Step 2

Connect floor and wall panels together using glue and screws. |

Step 3

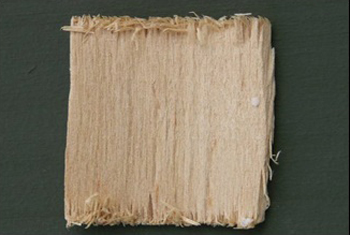

Remove bits of honeycomb core to implant solid wood for stronger fastening. |

|

|

|

| Step 4

Connected wall and roof by implanting solid wood for roof to fasten lightweight panel walls and lightweight roof panel. |

Step 5

Sing Honeycomb roof substrate panels come highly insulated straight out of the factory. |

Step 6

After the roof, your Sing Tiny House is ready to paint and install windows and doors. |

Visit our how to build videos on youtube

__________

How to build a Tiny House – By Little House on the Trailer

www.thelittlehouseontrailer.com

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Visit the Gallery to view more pictures!

Below Left: If you look closely, you’ll see that this Sing Tiny House is sitting on a furniture dolly.

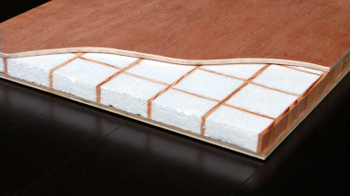

Above Right: Sing Honeycomb panel has minimal deflection under heavy weight.

Learn more about the strength, and “Green Aspects” of Sing Honeycomb panels click here