General Specifications

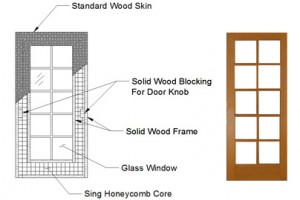

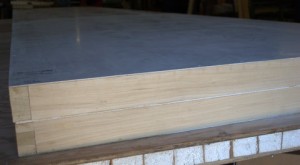

Fire retardant doors made with our patented Sing honeycomb/torsion box cores. Natural wood lock blocks are positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is wood framed by 1 ¾ “ natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering noncombustible 3mm Magnesium Board (standard) which results in 0 Flame Spread and 0 Flame Development.

Fire retardant doors made with our patented Sing honeycomb/torsion box cores. Natural wood lock blocks are positioned at locations as necessary for locking mechanism placement or as anchor points. The core material is wood framed by 1 ¾ “ natural wood for finishing strength and attaching hardware. The torsion box is completed by adhering noncombustible 3mm Magnesium Board (standard) which results in 0 Flame Spread and 0 Flame Development.

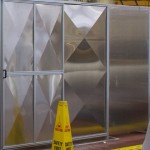

Additional exterior (skin) options can be applied to the fire retardant door to meet your specifications and/or match appearance of designed structure. Bonding agent used in adhesion of the entire composite material is formaldehyde-free. The fire retardant Magnesium Board is a Class A product that meets ASTM E 84 certifications.

Lightweight

Your Sing Fire Retardant Door weighs more than 60% less than other fire retardant doors when compared to other core materials. The reduced weight allows Sing Fire Retardant Doors to be utilized an applications where larger or heavier doors are just not practical or feasible.

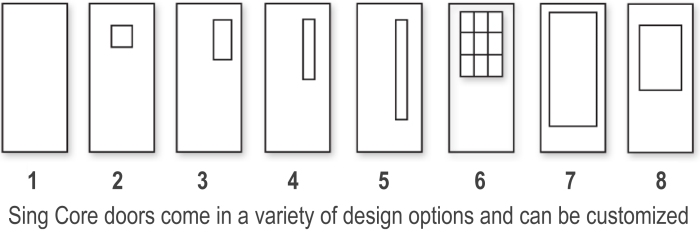

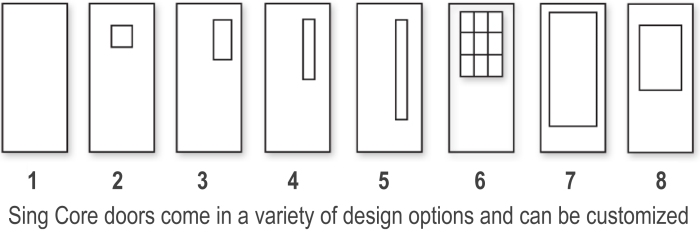

Available in Any Size

Sing Fire retardant Doors are available in any size and are custom built to your specifications.

Click here for tips on How to Create the Right Sing Panel for your specific project.

Every Sing Core manufactured fire retardant door is unfinished (unless specified otherwise) and is guaranteed for 10 years for structural integrity.

Detailed Specifications:

Scope: Subject to local building codes, the standard Sing Core fire retardant door is intended for use in:

- Single family dwelling interior applications

- Multifamily dwelling, low-rise professional office, library and low-rise motel interior applications

- Lighter use industrial building and factory, hotel and retail sales building interior applications

Product Description: 1 ¾” side-hinged fire retardant door panel manufactured by Sing Core

- Door component includes paint-grade door panel only

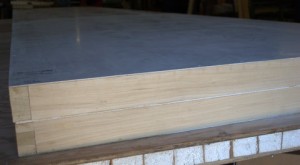

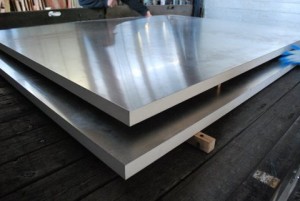

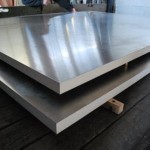

Door Panel Materials: Sing Core fire retardant doors are manufactured using Eco-friendly cold-press process. Composite materials include:

- Sing Core vertical wood-grain torsion substrate filled with recycled EPS foam

- Solid wood implants are inserted as lock blocks or anchor points

- Core material is framed with wood stiles and rails

- Facings are 3mm (adjustable according to individual fire-rating performance specs) Magnesium Board

- Formaldehyde-free bonding agent is used for adhesion of all components

Formaldehyde-free: This will help qualify for LEED credit points under MQ 4.4.

Additional Facing Material(s)

Your sing Fire Retardant Door can be custom-designed to host an additional facing material to match the look and feel of your project. Nearly any additional flat exterior building material can be added without compromising the fire resistant door.

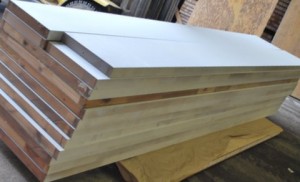

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core fire retardant door from factory to your location including proper crating to protect the natural beauty of your door during transport.

Delivery: Reasonable care is taken to ensure safe transportation of your Sing Core fire retardant door from factory to your location including proper crating to protect the natural beauty of your door during transport.

Storage and Protection: Store your fire retardant Sing Core door in an upright position and allow to acclimate to room temperature following shipment receipt or prior to finishing or installation.

Preparation: Per manufacturer’s specifications, ensure that door frame openings are constructed plumb, true and level prior to installation. Select fasteners of adequate type, number and quality to assure proper function.

Installation: Installer shall be specialized in the installation of the type of work that is associated with the project and will comply with manufacturer’s installation policies and procedures to ensure proper end use.

- Verify that hinging and latching assemblies operate freely and correctly

Finishing: The finishing of the Sing Core fire retardant door is the responsibility of the client due to the product being delivered in paint-grade quality unless specified otherwise in writing. Any sealing must be in accordance with manufacturer’s specifications to protect against a variety of environmental conditions as necessary.

- Seal all 6 surfaces with two coat minimum on operable panel(s)

- Finishing or re-finishing must be completed following acclimatization and installed within 7 days

- Avoid finishing after rain (or damp) or during periods of higher than average humidity

- At least once a year, conduct periodic inspections of coating to ensure no door components are exposed

- Reseal the surface as necessary

Machining: Sing Core fire retardant doors are easy to work with in the millwork shop for CNC machining or on-site for finishing, sawing, sanding, cutting and fastening. No specialized skills or equipment is necessary, other than standard woodworking tools. Treat Sing Core fire retardant doors just like you would any other standard door blank.

Strength Performance: Patented Sing Core has an unsurpassed strength as compared to other lightweight substrate materials tested at 660 PSI (based on 2″ x 2″ grids and 3/4″ thick) for superior structural integrity and is resistant to warp, twist and crack when compared to other materials.

Light Weight Performance: Sing Core weighs much less than other traditional building materials, as much as 50% less; or more, as little as 4 lbs. per sq. ft. yet sustainable and true green technology.

Insulation Performance: Standard Sing Core doors feature built-in insulation value with an R3 (can be upgraded to to R6.5 or more) rating per inch, depending on architect’s specifications.

Acoustical Performance: Sing Core standard doors have a natural sound-deadening quality for noise control. Standard sound transmission class (STC) is 30. Additional noise control specifications can be met at the behest of the customer or designer and must be noted in advance.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste. The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Warranty: Sing Core manufactured doors are structurally guaranteed for 10 years under normal conditions.

See also: Door Technical Information

How to Buy

To order Sing Fire Retardant Doors submit an order form either by email, info@singhome.com, or print and fax it to: 360.495.4585. We’ll provide a quote within one business day. If you have questions, please contact us.

Easy Ordering

All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. Getting a quote for your specialty product, is easy, thanks to our simple online order system.

Bulk Discounts

If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantity and wholesale inquiries are encouraged. Feel free to contact us for more information. Click here for Closeout specials.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Fast delivery: Any thickness and almost any length, less than 5 ft wide, can be made with in 48 hours if it is rush order.

SINGCORE Fire Retardant Doors are easy to order. You may choose from our stock panels or order custom sized panels. Our price is based on the length, width, thickness, and quantity. Submit a Work Order by fax or email, and we will give you a quote within one business day. If you have a tight budget, give us a call, we might have an alternative solution tailored to your needs.

If you Google true flat doors you will see what the latest technologies are, and you might be surprised to find that Sing Core is leading the wave of this new generation of doors that can be true flat in any size (even extremely oversize), super strong, yet lightweight and Eco-friendly. Sing Core might be the perfect match for your discriminating clients/customers. Why not give them a better door that costs less?

If you Google true flat doors you will see what the latest technologies are, and you might be surprised to find that Sing Core is leading the wave of this new generation of doors that can be true flat in any size (even extremely oversize), super strong, yet lightweight and Eco-friendly. Sing Core might be the perfect match for your discriminating clients/customers. Why not give them a better door that costs less?