|

Why Sing Core veneer structure is “Green” and the most earth friendly way to use natural and manmade materials?

Many people ask… “Is the foam used in Sing honeycomb core a green product?”

The answer is yes when looked at in terms of sustainability.

The life cycle assessment (LCA) is emerging as the accepted way to determine the true environmental impact of any product. LCA provides a “cradle to grave†measurement of a product’s environmental impacts from raw material extraction and manufacturing through distribution, use, maintenance, and disposal. A good example that we are all familiar with is a coffee or tea cup made of Styrofoam or a coffee mug made of same material but enclosed in a solid container. Solo cups are only used once than thrown away as garbage to fill our land fill. But the same solo cup material made into a permanent coffee mug could last 10 years without being replaced. You will agree that the same materials use, life span, and impact on the environment are the way to judge green and non green. The cost of solo eps foam cup is not only how much you spend for 10,000 cups during 10 years of time. (Assuming: 3 times a day x 365 days, times 10 years = 10,000 solo cups to the land fill from one person.) ——- But the total cost is the energy to produce, ship raw materials, and disposal. LCA studies show that wood is better for the environment than steel or concrete in terms of embodied energy, global warming potential, air emissions, water emissions, and solid waste production. Sing Honeycomb core structure is made of 100% natural vertical grain wood veneer. This sets us apart from our counterparts who use paper, particle board, aluminum, and plastic.

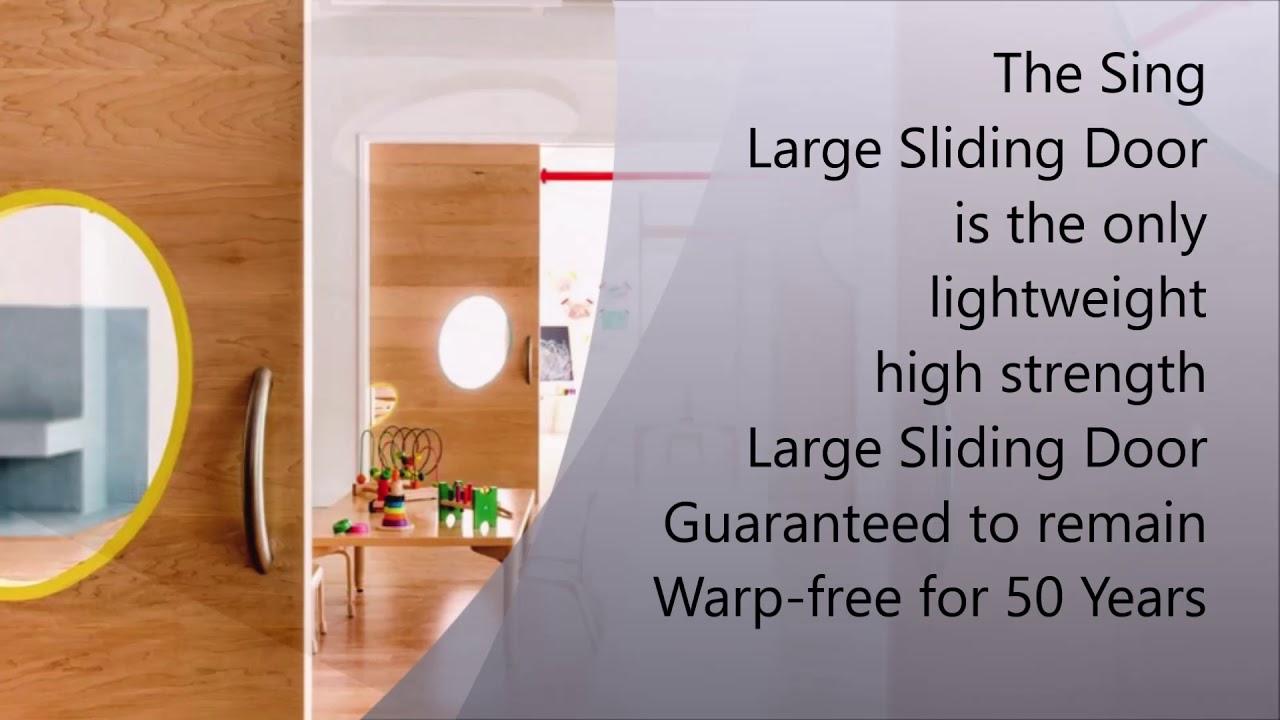

Furniture made of honeycomb can last 10 times or longer than furniture made of paper honeycomb, and particle board. If the price of Sing Core furniture is divided by 10, it will be the most economic furniture on the market today.

If you consider the life span of these products than you will agree Sing honeycomb is the answer for green products. Sing honeycomb products are made of recycled foam, and 100% clean wood veneer.

Sing honeycomb reinforces, reduces the weight and replaces the high energy consuming materials such as wood, plastic, metal, fiberglass, and concrete with minimum impact to the earth.

The following is the energy consumption comparison of sing honeycomb vs. wood, and wood vs. the other man made materials for your reference.

The energy consumption of wood products vs. others:

The energy required to produce one ton of wood is much less than that for other materials.

Compared to the energy required to produce a ton of wood, it takes:

5 times more energy to produce 1 ton of cement

14 times more energy to produce 1 ton of glass.

24 times more energy to produce 1 ton of steel.

126 times more energy to produce 1 ton of aluminum

Sing honeycomb vs. wood, —— Sing honeycomb only has 10% or less of wood and almost 90% of air. It is the strongest lightweight, renewable material made of vertical grain natural wood veneer fiber. Products made of Sing honeycomb core are the strongest lightweight renewable products available at a low cost.

Deciding if a product is “Green” should be based on the Life Cycle Assessment and energy consumption required to produce, transport, and dispose. This is why Sing Honeycomb is a truly “Green” product.

Facts about Polyurethane Foam

Heating and cooling costs amount to 50% to 70% of the energy used in the average American home, according to the U.S. Department of Energy. To stem these costs, maintain uniform temperature, and lower noise levels in homes, as well as commercial properties, builders turn to rigid polyurethane and polyisocyanurate (polyiso) foam — one of today’s most effective insulation materials available for roof and wall insulation, insulated windows and doors and air barrier sealants. Polyurethane use in building and construction accounts for more than 25% of the total polyurethane market in North America. Heating and cooling costs amount to 50% to 70% of the energy used in the average American home, according to the U.S. Department of Energy. To stem these costs, maintain uniform temperature, and lower noise levels in homes, as well as commercial properties, builders turn to rigid polyurethane and polyisocyanurate (polyiso) foam — one of today’s most effective insulation materials available for roof and wall insulation, insulated windows and doors and air barrier sealants. Polyurethane use in building and construction accounts for more than 25% of the total polyurethane market in North America.

Rigid polyurethane and polyiso products deliver a unique combination of properties, as described below.

Energy Efficiency

- Polyurethane and polyiso foams have one of the highest insulating R-values per inch of all commercially available products today. With typical values in the range of R 5.6 to R 8 per inch, it is possible to have thinner walls and lower profile roofs while maximizing efficiency, increasing space utilization and reducing operating costs.

- Increasing the thickness of polyiso roof insulation by 1 degree or more above the ASHRAE required thickness significantly reduces your energy costs while providing a positive rate of return on the cost of installation.

- Entry doors having a rigid polyurethane foam core help inhibit sound and add insulation value that further reduces heating and cooling energy needs.

- Polyurethane foam sealants, applied on-site, expand to fill energy-wasting, air-infiltrating gaps around window frames, plumbing pipes, and electrical outlets.

- Energy studies performed by Texas A&M on their own roofs show the energy cost reductions obtained by applying spray polyurethane foam (SPF) to more than 8 million square feet of roofing paid for the cost of the retrofit in a little over three years.

- “Reflective†plastic coverings over polyurethane foam-insulated roofs bounce sunlight and radiant heat away from a building, helping the structure stay cool and reducing energy use for air conditioning.

High Performance

- Rigid polyurethane and polyiso foams are made with a remarkably strong, yet lightweight, low-density structure that is both dimensionally stable and moisture-resistant with low vapor transmission.

This special combination of properties allows manufacturers to design thermal insulating products that are self-supporting, can be combined with a wide range of substrates while requiring no additional adhesive, and — when combined with the proper materials — perform as external weather and moisture barriers.

- High-performance polyurethane insulation can be spray applied to various substrates, or molded to special shapes in relatively large sizes. It can also be protected against UV degradation and re-coated to extend performance life.

- Polyurethane and polyiso products, when properly installed, are not affected by oil-based waterproofing or dampproofing compounds, insecticides or fertilizers.

- Both polyurethane and polyiso foams are widely used in the fabrication of steel faced building panels for various categories of commercial building construction. Applications range from cold storage warehouses used in the food and beverage industry to high-tech looking offices, medical buildings, airports and even manufacturing facilities. When bonded to metal skins, a composite building unit is formed with long spanning capabilities. The light in weight and high insulation value make these products ideal for renovating exteriors of older buildings because typically the existing building cladding can be left in place and the existing structure does not need to be reinforced.

Versatility

Thermal/Mechanical Performance

- The qualities of rigid polyurethane and polyiso foam reduce energy transfer, resist moisture, maintain dimensional stability, remain airtight and often support a structural role.

Polyurethane and polyiso foams also function in temperature extremes, do not deform or distort, and are not subject to damage by the moisture that may result from condensation. Polyiso is stable over a wide temperature range (-100°F to +250°F) and can be used as a component in hot- asphalt roofing systems.

- The mechanical strength of these foams is remarkable. High compressive and shear strengths allow low-density insulating cores to be faced with relatively thin steel or aluminum, yet span long distances unsupported. For example, the foam can hold together many of the components in a refrigerator or hot-water heater while it continues to perform as thermal insulation. This unique combination of properties allows rigid polyurethane foams to be used in many diverse applications.

- Polyiso roof insulation is a Factory Mutual Class 1 material approved for use in all types of roofing systems without a thermal barrier, saving both labor and material while providing the best energy efficient roof available.

Environmental

- The environmental benefits of rigid polyurethane foam are significant, and include increased energy efficiency and reductions in energy-efficient construction costs, reduced project weight and savings of all the construction components that the material replaces. Given the widespread adoption of rigid polyurethane foam in today’s construction, these savings are multiplying at an increasing rate around the world.

- Better insulation typically results in lower energy use. In some cases, mechanical heating and cooling equipment can be downsized, further increasing space utilization.

- Buildings can be constructed with thinner walls, while roofs require shorter fasteners.

- Less complicated and lighter-weight products are usually produced using fewer manufacturing steps, less energy in manufacturing, and less energy in transportation.

- By increasing the thickness of polyiso roof insulation by 1†or more above the ASHRAE required thickness in commercial buildings, it reduces CO2 emissions by thousands of pounds, SO2 emissions by thousands of grams, and NOx emissions by thousands of grams per year and the energy conservation achieved by insulating and sealing the building effectively helps reduce CO2 emissions associated with the burning of fossil fuels.

Rigid polyurethane and polyiso foams contribute to society and culture by conserving resources. Their ideal properties exceed those of any comparable material in strength-to-weight ratio, R-value and durability, while their versatility enables builders to use them for dozens of different applications, each yielding high performance and exceptional energy efficiency.

Click Here to read article written by Green Builder Magazine

|