Sing Sandwich Panel

The next stage in our patented green building material is the Sing Sandwich Panel that increases the strength of the Sing Core by completing the torsion box design. Need more strength? By increasing the thickness of your Sing Sandwich panel by two, the strength is multiplied by four. Four times the strength at very little added weight.

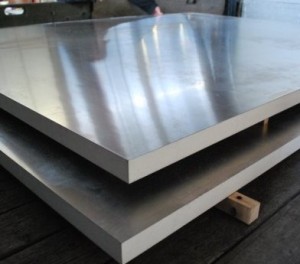

Sing Sandwich Panels are an open-ended Sing Core base sandwiched between two wood skins without solid wood or any other material along 4 sides of edges. (See photo to the right.)

Each Sing Sandwich Panel is made of Sing core with wood base skins used as filler. Our Sing sandwich Panel is designed to protect Sing core with wood base skins providing a better bonding surface for adding solid wood block, solid wood edge and final skin resulting in a completed Sing Core Panel.

Standard Sing Sandwich Panel Dimensions:

- dimension: 12 inch x 48 inch to 4 ft x 8 st

- thickness from 1/2 inch to 6 inch.

Sing Sandwich Panel Skin Option Examples:

… just to name a few, as the possibilities are limited only to any available flat building material.

Applications of Sing Sandwich Panels:

Use as sandwich panel block to drop in any solid wood frame, inbetween two sheets of plywood or any skin materials and cold press with adhesive (in most cases regular carpenter glue will work if it is a wood based skin) to build Sing Core Panels or any other type of Sing products.

Sing Panels

Sing Core Panels have the appearance of their traditional plywood or solid material such as aluminum blank, solid metal, solid concrete, solid fiber glass but Sing Core Panels are stronger than steel pound-for-pound, lighter than any currently available plywood or solid materials (50 percent ligheter that traditional plywood or less) more true flat than any known plywood and absolutly flat if made of aluminum skin).

Sing Core Panels are Sing Core enclosed and framed with any material available on four exterior edge sides, any solid implants are pre-installed prior to enclosure by top and bottom panels.

Sing Core Panels are available in large almost seemless sizes; as large as 12 ft wide x 48 ft in length, and available as thick as 6 inches.

Dimensions: custom manufactured to any size specifications from 1 ft x 1 ft to 12 ft x 48 ft

Thickness: from 1/2 inch to 6 inches

Examples of skin options for Sing Core Panels include:

plywood

plywood- solid wood

- MDF

- aluminum

- cold roll steel

- galvanize metal

- stainless steel

- plastic

- fiber glass

- cement board

- concrete

- ceramic tile

- glass

… just to name a few, as the possibilities are limited only to any available flat building material.

Sing Core honeycomb panels come in any thickness from 1/2 in. to more than 8 in. size of Sing panels;The largest door/movable wall we build are 32 ft wide x 16 ft in length (It weighs less than 800 lbs App. 1.5 lb per sq ft),With our patented Sing core biscuit layin under each join which keep the Sing large oversize panel true dimensionally stable without any movement due the the temperature and moisture change (We offer a 10 year structural guarantee) paint grade.

Sing Core honeycomb panels come in any thickness from 1/2 in. to more than 8 in. size of Sing panels;The largest door/movable wall we build are 32 ft wide x 16 ft in length (It weighs less than 800 lbs App. 1.5 lb per sq ft),With our patented Sing core biscuit layin under each join which keep the Sing large oversize panel true dimensionally stable without any movement due the the temperature and moisture change (We offer a 10 year structural guarantee) paint grade.

We are so certain that Sing Core is the solution to your green building challenges that we offer a 100% refund for any prototype order, for those who want to test drive any form of Sing Core products for use in their applications, so you have nothing to lose. Click Here for our convenient online order form.

What are the most popular Sing Products?

At the top of the list, by far, are large sliding doors and oversize doors of any design. Sing Core has been answering the call of architects and designers providing them with the solutions that they need to see their visions come to life.

Patented Sing Plywood

Patented Sing Plywood and Panels are the main course of Sing Core technology. The benefits of this lightweight, super-strong green building material is the penacle of our process. Leading the way in thousands of applications that can benefit from this new revolution Patented Sing Plywood and Sing Panels are replacing old, solid, overweight building materials that are not created using the same green manufacturing process as Sing Core.

Sing Core is created using less energy, less manpower in less physical space and produces less waste than other building materials.

Patented Sing Plywood (PSP) enables you to use a lightweight, strong, wooden honeycomb panel empowering you to create anything from basic furniture or large sliding doors to create affordable housing with unparalleled logevity. But PSP is less expensive and more environmentally friendly. As unbelievable as it may sound, PSP gives you an incredible advantage over other types of traditional plywood. This new and innovative building material is so much more than lightweight, strong, and durable; it is long lasting, reliable, simple, and affordable.

With an appearance identical to traditional plywood, the physical characteristics are nothing short of shocking in comparison, as Patented Sing Plywood is stronger than steel pound-for-pound, more lightweight than any plywood or solid building material (1/2 the weight of standard plywood or less) and more true flat than any plywood available on the market.

Patented Sing Plywood Dimensions:

- custom to any size from 1 ft x 1 ft to 12 ft x 48 ft

- available in large almost seemless oversized panels

- as large as 12 ft wide x 48 ft in length

- as thin as 1/2 inch

- Can be as much as 6 inches thick

Patented Sing Plywood Skin Options:

- Plywood

- Any solid wood

- MDF

For other non-wood finish skin options, see Sing Panels

Applications of Patented Sing Plywood:

Use as as substrate to glue hot press veneer, cold press wood staves, with proper glue, adding skins of any material such as aluminum, metal, fiber glass, plastic, cement board, or paint ready for doors, table tops, walls, floors, ceilings … see Sing Products.

Think about it…

Why use thick plywood- that can be difficult to construct with- when you can use the versatile Patented Sing Plywood? Through Sing Core, you will have the components to be able to build thousands of Sing Core products, with eco-friendly touch sustaibability.

Patented Sing Plywood is Sing Core enclosed and framed with solid wood on four exterior edge sides, any solid implants are pre install before enclosure by top and bottom wood panels.

Sing Wood

Sing Wood has better appearance than solid wood, are elongated and rectangular solid wood on six sides, a lightweight super-strong eco-friendly alternative to solid wood material used in carpentry and the construction of ships, houses, bridges and other structures.

Solid wood skin covering is available in any thickness from 1/8 inch to six inches. (Note that plywood is only .020 thick and cannot withstand sanding or machining.)

If the exterior wood surface is less than 1/4 inch, the inside of Sing Wood is our patented torsion-box sandwiched plywood as a substrate to keep the structure forever flat, which natural solid wood cannot obtain the same stability. If the exterior wood surface is greater than 1/4″, the inside is standard Sing core. Solid wood is heavier and not as strong according to the weight/strength ratio.

Sing wood is available in any width from eight to twelve inches and any length up to 50 feet long.

Advantange of Sing Wood vs. Plywood & Solid Wood

| Machine? | Dimension Stability |

Lightweight? | Strength to Weight Ratio |

Eco-friendly | |

| Sing Wood | Y | N | Y | Y | Y |

| Solid | Y | Y | N | N | N |

| Plywood | N | Y | N | N | N |

Case Study:

- Wood flooring

- Wood Ceiling

- Wood Siding

- Wood Scaffolding

- Shelving

- Stairs

- Staircases

- Wood plank walls

- Butcher Block

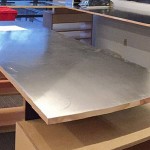

Sing Aluminum

Aluminum face sheets over patented sing core. Sing core aluminum panels are lightweight, dent resistant and stronger than steel in inch-per-inch independent tests. Sing core aluminum panels are used where impact is likely to occur.

Our sing core aluminum honeycomb sandwich panels are the solution for a wide range of applications requiring guaranteed flat, light weight, and rigid specifications.

Patented Sing core aluminum panels are stronger than steel pound-for-pound, utilizing a 2×2 inch grid with our patented design and process ensures more strength in comparison to aluminum core.

Other advantages of the patented Sing core honeycomb panel includes sound deadening, built in insulation, features a stronger core and is eco-friendly.

Advantange of Sing Aluminum Panels vs. Other Aluminum Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio |

Eco-friendly | |

| Sing Aluminum Panel | Y | Y | Y | Y | Y |

| Solid Aluminum | N | N | N | N | N |

| Aluminum Honeycomb | N | N | N | N | N |

Easy to close edge, edge banding, install solid wood implant at any location which provide stronger bonding

Easy to close edge, edge banding, install solid wood implant at any location which provide stronger bonding

Case study.

Aluminum out door bench.

Veneer face aluminum door.

|

|

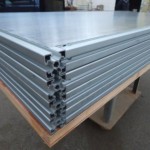

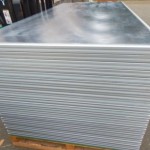

Sing Metal Panels

Sing Honeycomb Metal Panels are stronger and lighter than other metal panels, which can be dented by something as small as a golf ball.

The torsion box core holds the Sing Metal Panel flat so that it will not warp and sag. A 16lb steel hammer will easily dent a steel or vinyl door, but not a Sing Metal Panel. Because Sing panels are efficient to produce, they are more affordable than solid steel panels.

Advantange of Sing Metal Panels vs. Other Metal Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio | Eco-friendly | |

| Sing Metal Panel | Y | Y | Y | Y | Y |

| Solid Metal | N | N | N | N | N |

| Metal Honeycomb | N | N | N | N | N |

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features.

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features.

Sing Core Cold Rolled Steel Panels have a wide range of applications, are not limited in length or width and though we excel in large projects, we also provide solutions for reduced dimesions for smaller projects.

The example to the left is an application that was used in material handling. This trough is constructed with 20 gauge cold rolled steel and is used for moving raw material.

The image to the roght is an example of a cut out that was made in the trough.

These are just a few examples of how Sing Core Cold Rolled Steel Panels are flexible and easy to use in a variety of applications.

See also Sing Cold Rolled Steel Panels

Specialty Panels