![]() When it comes to earth-friendly products, nobody knows more about it than Mother Earth News… So, when they are having their trade show(s)… who do you think they turn to get lightweight eco-friendly materials for their displays?

When it comes to earth-friendly products, nobody knows more about it than Mother Earth News… So, when they are having their trade show(s)… who do you think they turn to get lightweight eco-friendly materials for their displays?

You guessed it: Sing Core.

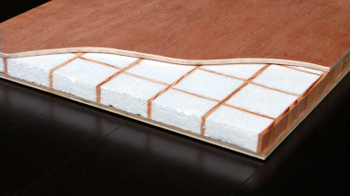

Why Sing Core? The answer is, because Sing Core is the only source using the patented technology that is the future of renewable and sustainability in building materials.

Sing Core Building Material is:

|

|

Think about it… What if you could make something that has the strength of stainless steel yet was extremely lightweight, while maintaining its integrity over long spans?

Certainly, this is the conundrum perplexing the minds of many architects, designers and engineers at this very moment… Sure, you might find something that will give you the strength that you want and need for your project, but in most cases, the cost of that strength is extreme weight.

That heavy weight can compromise your project, sending you back to the drawing board.

I don’t know how many times we have received calls thanking us for saving a project that would have ended up in the trash, had it not been for our lightweight and super-strong technology.

But that’s not all that you get with Sing Core’s approach to design and production solutions…

Sing Core has other attributes that are very compelling, for instance, Sing Core is bio-friendly. In a world that is on the brink of over-using its valuable natural resources, it is important for all of us to do what we can to nurture our planet and take responsibility for what resources we consume.

Sing Core is manufactured with minimal amounts of natural resources and recycled material in a manner that requires less energy to create than any other building material, and produces less waste.

Sing Core is also designed with longevity in mind. In our increasingly disposable society, manufactured products are built using cheap material and components… and the best-selling items are built off-shore due to the lower cost of production, making it hard for Americans to compete.

Cheaply-manufactured imports have a life-expectancy of what? Two years? While Sing Core will last lifetimes without structural degradation, which means that we can build products that can be left to future generations that are not expendable or disposable.

Whatever happened to our Made in the USA pride in manufacturing that this country was built on?

Sing Core is fighting hard to bring back American pride and our economic infrastructure by making this space-age building material available to every woodworker who wants to build something meaningful and profitable. This will make the world a better place by supplying beautiful, high-quality products that are not so expensively made to put them outside the reach of the average consumer.

As a matter of fact, Sing Core’s inventor, peter Sing is so committed to rejuvenating the economy with his grass roots approach to a new, “true green” revolution, that he is training individuals in his patented technology via Lightweight University.

Scholarships and subsidies are available for one-man operations and artisans, as well as independent businesses. Training and licensing is also available for mega builders and manufacturing facilities, for those who truly want to make a difference for preserving our planet and producing a superior end product.