FAQ

What Are Sing Panels?

In the aircraft industry, they call it honeycomb. In the woodworking industry, it is called a torsion box. In the home industry, it is known as a sandwich panel. No matter what you call it, Sing Core’s honeycomb panels have the strongest, most lightweight earth friendly core to structure your Sing Core panels. Sing Core panels has more applications than any known material; use it for home construction, boat building, private jet furniture, home furniture, museum and trade show display, and doors. Patented Sing Core panels are a hybrid of torsion box, sandwich, and honeycomb panel. It has the flatness of a torsion box, the strength of a honeycomb panel, and the light weight of a sandwich panel. Sing Core panels combine all of these characteristics to form the most earth friendly panel in the industry.

How Do I Order Sing Panels?

If you are an architect, wholesale supplier, millwork, or other trade professional, submit a price quote from our pricing page.

Dear Homeowner/DIY’er, unfortunately we do not sell to individuals, only to the building trades and commercial/wholesale companies. Please contact your local millwork and request that they order your panels for you. We will then work with them to utilize Sing Core for your project.

How to Handle and Deal with Sing Products

Our best long-standing clients know how to best handle and deal with Sing Core products due to their high level of expertise. We welcome new clients to enjoy the benefits of patented Sing Core products. If you are a potential new user of Sing Core you are advised to make yourself aware of how to handle and deal with Sing Core products before ordering any patented Sing product(s).

Can I Get a Discount?

You may be able to get a special discount in exchange for professional photographs of your project. You can ask at the time you place your order, if you might like to participate in our photo marketing agreement. You will pay the price on your invoice and receive a check from Sing Core as a rebate in the amount noted on your invoice following the receipt and approval of your photos.

Photo Marketing Rebate?

Your job may qualify for our marketing rebate entitling you to a percentage of your order or agreed upon amount for providing Sing Core with acceptable drawings, pictures, videos, and reviews of your special project demonstrating the positive attributes of Sing Core in the field. To be entitled to your marketing rebate, you must request it and have your request approved prior to placing your order with Sing Core.

How do I fasten to your panels?

Our panels have a solid wood frame and block inserts can be implanted inside the panel to create secure anchoring points. Anchoring points can be used for placing hardware, overlays, and even fastening the panel.

Stiffeners can be implanted to ensure a true-flat panel. The necessity for stiffeners depends on the overall size of the panel, application, and weight.

For more information, see our custom blocking page.

What glue do you use?

Our panels are bonded with an extremely strong and waterproof adhesive. Our adhesive is 100% formaldehyde free.

What are your skin options?

Skin choice is one of the biggest factors to avoid warping.

It is important to choose a skin that is non-permeable. Permeable skins allow moisture to be trapped in the skin material causing it to swell. This can cause structural issues over time.

Wooden doors have the most problems with moisture absorption.

It is important to specify exterior grade when needed for your application.

Skin choice can affect sound deadening capabilities and is important for adhering to a certain Sound Transmission Class (STC) rating.

Multiple layers of skin can be applied to a panel. This allows the panel to have the strength of plywood as well as the smoothness of MDF. Layering skins can also be used to aid in producing fire-resistant panels to comply with certain fire code regulations.

Can I have dissimilar skins on my panel?

Dissimilar skins may be possible depending on your panel’s thickness. Please discuss this with your sales representative for more information.

Do I need to calibrate my panels before veneering?

Yes.

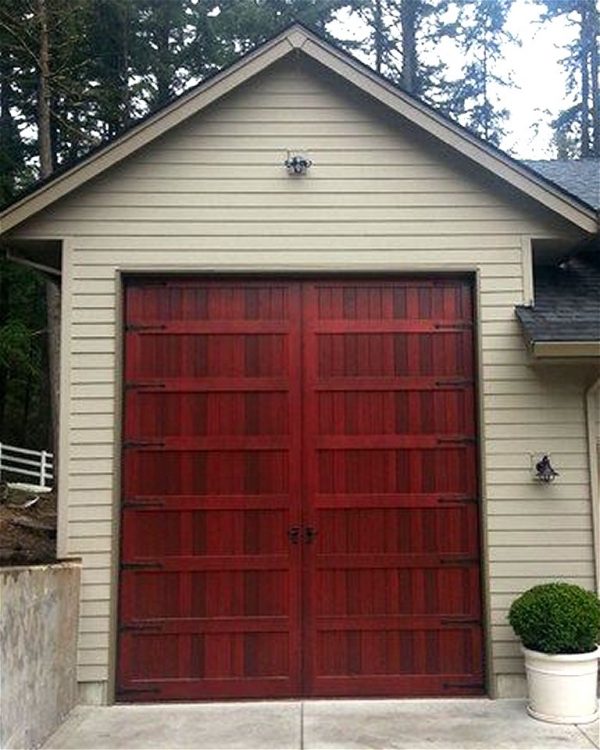

How do you handle such large doors?

Oversized panels are panels with dimensions over 4’ x 8’.

Oversize panels are often more difficult to handle and more costly to ship.

Luckily, we have devised a method to overcome this. The Sing Spline allows us to ship oversized panels in modular sections that can be joined at the work site. See Sing Spline for more information.

Almost any door can be made with Sing Core. Stile and rail style doors can be made by simply adding trim or molding pieces; however it will be much stronger than a traditional stile and rail door.

What is True Flat?

All Sing Core products are guaranteed true flat; that is to say that they far exceed AWI industry standards or ¼ inch deflection to be considered flat. Specific degrees of flatness can be achieved and guaranteed based on your requirements, specifications and application. See What is True Flat? for more information.

What is the difference between your core and your Sing Core panels?

| |

|

|

Sing Core Structural Core

Honeycomb Core which is based on Torsion Box technology to be lightweight but strong. You would then add skins and edging as you desire.

|

Sing Core Panel – No Edge

Sing Core that has a skin on the front/back of it, which improves its strength and gives you a working palette for your project. You would then edge band as desired.

|

Sing Core Panel – With Edge

is the complete panel

for your use, with core, skins and solid wood edging this is ready to then be completed and installed by you

for your project.

|

What edging options does Sing Core provide?

Sing Panels can feature a 1.25 inch solid wood edging. Other sizes are available as custom options as well. Edge-banding is available at an extra charge. Sing Core panels can also be purchased without an edge.

Why Do Sing Core panels have such a long lifespan?

Patented Sing Core panels use zero formaldehyde structural glue to bond Sing Core and the surface material creating the strongest lightweight eco-friendly sandwich panel/honeycomb panel, see comparison. The patented Sing Core panel is nearly unbreakable due to being so lightweight and strong. Even if damaged by rough handling, Sing Core panels can be repaired to their original strength (Our patented structural core and stress skins are much easier to repair than solid wood, MDF or plywood).

Why is my Initial Price Quote different from my Final Price Quote?

As a courtesy, Sing Core provides an introductory initial price quote in response to your initial request as an introduction to your salesperson, who will help to work out the details of your order. This is somewhat automated and is only based on information which is entered into the fields in the your price quote request and is not binding in any way. In most cases, this is very similar to the Formal Price Quote that you will receive from your salesperson. In some cases, depending on the project, the intricacies of the final door build are very different and not included in the initial price quote. In other cases, if the initial price quote is over budget, the door blank(s) can be re-engineered to accommodate a tight budget. Talk to your Sing Core sales person to work out the details.

What is the weight of your panels?

The weight of our panels are based on many factors, W x H x T, the types and thickness of the skins chosen and of course the solid wood edging as well. But for a rough ballpark estimate the weight of one of our standard panels 4’ x 8’ x 1” (finished size = 47” x 95” x1”) is somewhere in the 25 to 30 lbs range depending on the skin, which is much lighter than standard plywood of the same size/thickness.

What’s the difference between Standard and Professional Sing Core panels?

Standard panels provide more than enough structural integrity and non-warping properties for most jobs, but for jobs that require true flatness, we also offer a Professional tier of Sing Core Panels. Professional panels come with a 50 year non-warp guarantee that feature our aluminum stiffener technology. Learn more about Sing Core Professional Panels here.

Can you nail into a Sing Core panel?

Yes. We recommend a ⅜ inch skin such as MDO or luan if you plan doing a good amount of screwing or nailing into your panel. You can also nail into a Sing Core panel with a ⅛ inch skin as required.

Our craftsmen can also install custom blocking for your projects at an additional cost. Please provide drawings so we can ensure a precise panel.

- We can place custom blocking in your panels as required by your drawings.

- Install a solid wood strip every 12 inches (or whatever your needs are).

How much wood do I need around the perimeter of a door panel?

The standard wood trim inside the perimeter of a Sing door panel is 1.25 inches. Old school technology would have you thinking that you might require a heftier wood frame inside. While that might be true for a hollow core, paper core, or other type of core door, it is unnecessary when using Sing door core as substrate. Sing Core is a composite solid core material which is stronger than steel pound for pound, and is often used for attaching hardware without the use of implants.

Even so, we do offer solid wood implants, like lock blocks, or any other location to accommodate your hardware specifications.

What are the lead times for new orders?

Lead time for new orders is 6-10 weeks. Every order Sing Core manufactures is custom made, so please keep that in mind in regards to your project’s timelines.

If you require a rush order, rush fees are as follows:

Ship in 4 weeks – 20% price increase

Ship in 3 weeks – 40% price increase

Ship in 2 weeks – 70% price increase

Ship in 1 Week – 100% price increase

Rush fee times are counted beginning the day you approve the shop drawings for your project.

Exactly how strong are your panels?

The strength of our panels depends on factors like span, thickness, and skin type. They have been independently tested by the University of Washington to exceed 660 PSI, and can be custom designed to achieve over 1,000 PSI per your specifications.

How well insulated are Sing Core panels?

The R-Value of a Sing Core sandwich core using EPS Foam is 3.5 per inch. For technical specifications on our EPS foam, please visit this page. The R-value of a Sing Core sandwich core using Urethane Foam is 6.5 per inch.

How big can you make Sing Core panels?

A standard sized panel is 4 ft. x 8 ft. We also specialize in custom sizes, which are available in any dimensions, up to 22 ft. by 40 ft. or larger.

Can you join together Sing Core panels?

Yes. One way to join Sing Core panels is with a biscuit. View this video to see how to join panels, or visit this page.

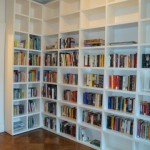

Can I bond other materials to the surface of Sing Core panels?

Yes. Many of our high-end millworks adhere other surface materials to a Sing Sandwich when used as substrate. Standard lightweight plywood surfaces are easily adhered to with regular carpenter glue and cold-pressed. If your intention is to laminate other materials to your Sing Core sandwich core, you should check with us first, to make sure that you are using the proper bonding agents) to achieve the results you desire.

Are your lightweight panels weather resistant?

Our panels are resistant to the degree of its surface material and/or its coating. Sing Core panels can be manufactured to withstand the most extreme weather conditions, and are even used in underwater applications.

Where do you distribute?

We distribute to anywhere in the world, and have delivered panels to Europe and Asia.

Do you do any licensing of your patented products?

We’d be happy to discuss licensing and partnerships. Please get in touch with us via our contact page.

What types of material can I laminate to honeycomb?

Any substrate (skin) that is capable of carrying a load.

What is a torsion box?

A torsion box is best explained by this article.

( http://woodworking.com/ww/Article/What_is_a_Torsion_Box_8816.aspx )

What is a “board foot”?

12″ x 12″ x 1″ = 1 Board Foot

12″ x 12″ x ½” = ½ Board Foot

12″ x 12″ x 2″ = 2 Board Foot

How much pressure do I use to apply skins myself?

Enough for intimate contact with our honeycomb core with or without solid wood edging but too much pressure can cause damage to the core. We recommend 660 PSI or less.

How can I build with my structural core and panels?

A: The different options of our Sing Core Structural Core and Sing Core Panels allows you to decide how you want to work with our patented core material. You can choose how much or little work you want to apply to the core*. (*when applying skins you will need to use a cold-press method unless you ordered hot-press ready panels)

Purchase just the core, you would then apply the skins on both sides and solid wood edging* (*place edging before apply top skin) or

Purchase core with skins* (*birch or luan) and apply the edge-banding or yourself or hire someone to do it or

Purchase the core as an all in one component* (core, skins (birch or luan) & solid wood edging)and receive your panels complete, just paint/seal and finish as you desire and install

What does paint grade not paint ready mean?

We deliver your panels as paint grade as opposed to paint ready, due to several instances where our definition of paint ready did NOT meet our customer’s definition of paint ready. Because of these issues, we now leave it up to the customer to get their panels to their preferred finished state.

What if I want 1/4″ MDF?

Instead of 1/4 inch MDF, we use our own plywood-backed MDF which is made by laminating 1/8″ plywood to a 1/8″ sheet of MDF. This still gives you the smooth MDF face to paint, hot press to, or apply other materials, like vinyl wrap(s). You get the same smooth surface with added high performance because MDF is prone to movement. If you have to have 1/4 inch MDF, we will make your panel to your specifications, but we may have to re-engineer the rest of the panel to assure high performance.

What surface materials are available for a Sing Core sandwich core?

Our standard surface material is Luan (lightweight plywood).

What are the fire retardant qualities of our product?

Foam: level 2, Panel: untested

How do you ship?

LTL Freight Company – common carrier

Arrange for pickup by your preferred carrier

Customer pick up from our facility here in McCleary, Washington

How do I seal the interlock?

It can be sealed with conventional caulking or waterproofing.

Isn’t Luan difficult to work with?

Our Luan is in the form of veneer, so the natural fragility of the wood isn’t a factor.

How do you fasten panels?

Fasten your panels with dowel, bolts, biscuit, camlock (rotorlock), or edge to edge glue. Visit our Fastening Page for details.

What wood species are Sing Core products available in?

We build to architectural specifications. So, whatever wood species is specified, we use that, if it is available. If it is unavailable, we contact the client to see if they are working with a wood shop/millwork who has the wood, and they can supply it to us. If the wood is not available via any known sources, then an alternative might be considered. The finisher, on the client’s end, should be able to match (or nearly match) the finish of existing wood on the project using a different species.

This is common with the doors we build because sometimes we are limited to length of species specified, and for large doors exceeding the length of given species, this can be a problem.

What kind of wood do you use for solid wood edging?

We use soft wood because it’s easy to control the moisture content and to fasten. Soft wood also weighs less than solid hardwood.

What if you use a basic interior door as an exterior door?

It’ll bend because moisture will get inside the door and press outward on the skin. We don’t guarantee for weather exposure because we don’t control how you treat the surface. If treated properly with urethane, your doors can withstand the weather.

Will Sing Core’s spline joints crack?

Because of the stability of the patented Sing Core, spline joints in sectional Sing panels/doors will not crack, unlike traditional solid wood which is not stable enough to be used in this application.

For FAQ around our other products, view these links: Doors | Trade Show Panels | Tiny House | Log Homes