What can you expect from Sing Core?

The best metal pivot doors, modern steel door, oversized pivot door, oversized sliding door or any door of any type, style or size that can be guaranteed not to warp, bend, twist or otherwise fail (including full structure warranty) for 50 years. No door can achieve such high levels of precision, performance or longevity unless it has patented Sing Core inside. Sing Core produces affordable pivot door evolution of entrance doors.

The best metal pivot doors, modern steel door, oversized pivot door, oversized sliding door or any door of any type, style or size that can be guaranteed not to warp, bend, twist or otherwise fail (including full structure warranty) for 50 years. No door can achieve such high levels of precision, performance or longevity unless it has patented Sing Core inside. Sing Core produces affordable pivot door evolution of entrance doors.

We are the manufacturers of Sing Core. We do not sell retail. We only supply the best architects, builders, manufacturers, millworks and door companies with patented Sing Core products that lift and redefine the limitations of weight and strength in building materials such as doors, panels, post and beams.

How Can I Get a Door with Sing Core Inside?

If you are interested in using patented Sing Core in your next project for its Eco-friendly lightweight and high strength characteristics and you are an Architect, Millwork, Trade Professional, or Wholesale/Distributor, please feel free to Click for Pricing.

If you are interested in using patented Sing Core in your next project for its Eco-friendly lightweight and high strength characteristics and you are an Architect, Millwork, Trade Professional, or Wholesale/Distributor, please feel free to Click for Pricing.

Homeowners or retail inquiries please contact your local trade professional or favorite door company and tell them you want a door with, “Sing Core Inside.”

Oversize Entrance Pivot Doors

“If we could build this giant warp-free wooden pivot entry door, we can build your door.” ~ Peter Sing

For thousands of years pivot doors have been the upscale preference of the most exotic high-end large oversize entrance doors relying heavily on the entry door hardware, specifically the pivot hinge, to manage the functionality of the pivot door.

Due to the size and weight of the conventional modern pivot door the heavy duty hinges and pivot door hardware could account for up to half the cost of the pivot door (e.g., a low end pivot door could cost $3,000, half the price will pay for the hardware due to the heavy weight), creating a high price point as well as being expensive to transport, handle and install.

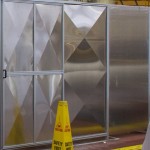

Yet, the most demanding clients desire this elegant outswing exterior door to make an extreme visual impact for the primary access point of their structure (while bringing the outside in and the inside out by way of the architect’s modern design concept) regardless of price to command attention via first impression.

Pivot doors may be the most expensive designer doors but there’s no escaping the luxurious feel that they lend to designs by top architects who help to create the most leading edge structure designs by featuring the best exterior doors.

Since hardware is of huge importance in a pivot door’s design and implementation, there are many options to consider including offset pivot hinge, commercial door hinges, heavy duty door hinges and center pivot door hardware in your pivoting door system.

Click Here to See Our Preliminary Pivot Door Industry Report

How to Build the Best Pivot Door

Structure of Pivot Door

1. Steel frame

- Very heavy

- Expensive to install

- Expensive hardware due to the Weight

- Less thermal break

- Less precision due to welding process

- Less compression strength which could cause surface dent under impact

See: Center for Architecture and Design Seattle’s large custom edge pivot doors w/man door (Sing Core is a platinum supporter).

2. Wood frame and/or solid wood pivot door

- Not strong

- Heavy

- Danger for kit to operate due to the heavy weight

- Less compression strength on the surface of the door—-potential structure after years of use.

- Potential to warp, twist, cup, bend

- Lack of high precision—which cause the leak of air, latch have problem to close or does not have a close tolerance to lock the door in place

- High cost for hardware and installation

- Lack of insulation

3. Frameless (don’t be framed)

3. Frameless (don’t be framed)

- Small grid torsion box

- Lightweight core panel/sandwich core/honeycomb core

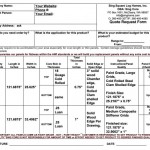

- High precision—-Sing Core tolerance within .+ or – .007 inch

- High strength—Sing Core door panel could design reach beyond 700 psi vs other lightweight core average 10 to 50 psi.

- Less hardware and install cost.

- Safe for kids to operate.

- Warp-free and structure guarantee for 50 years

The best large door guarantee in the world; make sure to ask the door supplier for warranty if you have a large door to be built.

You do not want to have a problem if investing in tens of thousands of dollars in your high end door. Patented and patent-pending Sing Core door panels will make Sing Core clients less worried about door warping or lack of structure strength over time.

Among those 3 type pivot door structure the frameless type is the strongest, lightweight structure click here to see all type of cores available to build pivot doors… You will find out that patented Sing Core is the best choice among all the other pivot door cores.

Google search: lightweight, high strength, insulated door

Highest Precision Maple Cutouts for Modern Pivot Doors

- High precision maple

- Straight warp-free maple

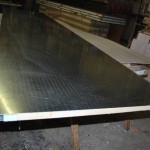

Steel Pivot Doors

Many pivot doors feature metal structures and framed composites and more popular for exclusive high security environments, commercial steel entry doors and even residential steel entry doors.

Many pivot doors feature metal structures and framed composites and more popular for exclusive high security environments, commercial steel entry doors and even residential steel entry doors.

How to Build an Exterior Door

Many considerations must go into the design, plan, building and installing a pivot door.

1. The Core Material

The core material that makes up the heart of your pivot door determines so much. Based on your choice of material you will determine your pivoting door’s:

- Weight

- Strength

- Insulation

- Precision

- Performance

- Maintenance

2. The Frame

Will your pivot door be a solid one-piece material construction, or will it be framed or unframed?

Many options about for the substance of your pivot door, first – the most heavy and likely the most unstable – is solid construction, then framing. Framing your pivot door can be with wood or metal, like steel or extruded aluminum. Wood will move framing with metals, like a conventional steel door, may not meet high performance specifications due to welding creating imperfections in the metals.

3. The Entry Door Styles

What will the general appearance of your door be? What exterior surface material, skin (see material options) or design will make your pivot front door stand out to make that impactful visual impression?

4. Hardware

What hardware will be required (price is usually influenced by style of pivot and finished weight of door) for optimal performance of your pivot door?

5. Installation

Who will install your pivot door and will any special handling/equipment be required for installation?

Can the Affordable Pivot Door Replace Contemporary Entrance Doors?

Until now, pivot doors have generally been too expensive for the average homeowner to consider, but one pivot door core material is changing all that. Sing Core manufactures an Eco-friendly pivot door core material used by the most high-end architects, designers, door manufacturers, millworks and contractors for building the best pivot doors in the world.

What constitutes the best pivot door in the world? One that is:

1. Eco-friendly (sustainable, true green)

Sing Core panels are constructed with natural wood fiber vertical grain torsion box filled with recycled rigid foam adhered between stress skins using formaldehyde-free glue for a solid substrate.

Sing Core panels weigh a fraction of the weight of other solid structural building materials.

3. High strength

Sing Core panels were independently tested by the University of Washington at 660 PSI for super-strength (compared to 10 to 110 PSI of other honeycomb cores used in the aerospace industry).

4. Insulated

Sing Core panels are packed with insulation rated at R 3.5 to R 6.5 (depending on foam selection) and feature sound deadening qualities for security and privacy.

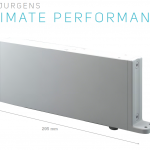

5. High Precision

Only Sing Core panels can be created to be true flat, within .006 inch tolerance with little or no deflection.

6. Versatile

Sing Core panels can feature any surface material (skin), like any wood species, aluminum, ceramic, concrete, fiberglass (FRP), HPL, Kevlar, LVL, MDF, stainless steel, stone or any other flat building material, may host any glass lite openings in any configuration and can be embellished to have the appearance of any style door imaginable.

7. Guaranteed not to fail

Only Sing Core’s professional pivot doors can be guaranteed true flat and to stay flat and not to fail for 50 years. (See free consultation).

Only by using patented Sing Core can any pivot door achieve such results.

How Can I Get a Sing Core Pivot Door?

There are many ways that you can make your pivot door dreams come true.

1 Architect

Architects have access to Sing Core technology and are specifying Sing Core in their pivot door designs – especially if they are large pivot doors – that can be manufactured by their favorite millworks.

2 Millworks

Most one-of-a-kind custom pivot doors are created by revered craftspeople and woodworkers who create hand crafted pivot doors for exclusive clientele.

3 Door Companies

Any door company can use Sing Core panel as the substrate for your pivot door. Though many do not feature the Sing Core pivot door as a standards catalog item, in most cases you can special order your pivot door with Sing Core technology.

4 Contractor

Sing Core pivot doors panels are sold without hardware installed and unfinished. Our door panels are manufactured for mill works to install hardware and finish. We do not recommend shipping Sing Core door panels the job site for installing hardware and finishing. This is not the best way to treat a high end door such as a large pivot door made with Sing Core. We highly recommend the GC work with millwork professionals to finish at their facility (except some special restrictions).

We believe each professional has it’s own specialized knowledge just like we do not expect an architect to install the door, instead using a highly trained GC.

Since the weight of your Sing Core pivot door will be a fraction the weight of a solid (or framed) pivot door you can save cash that would have to be invested in heavy duty pivot door hardware that could account for half the cost of any other pivot door.

Plus you save on transportation and installation costs, just like our clients (see clients list) and enjoy maintenance-free high performance of your pivot door.