1 Best Building System

1 Best Building System

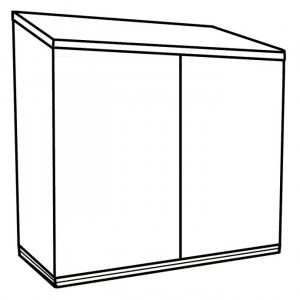

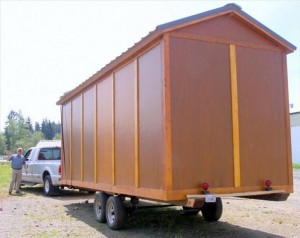

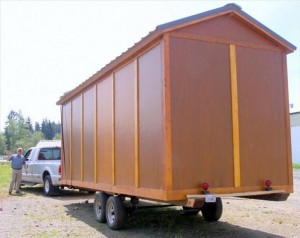

If you consider the following factors: Now you can build the best insulated shed to protect your belongings from moisture, mold and mildew for your backyard, use as an outbuilding or storage garage in hours instead of days thanks to Sing Core.

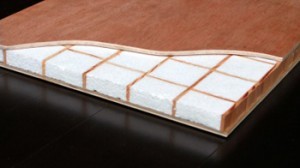

It doesn’t matter if you are building a Sing shed, Sing tiny house, not so tiny Sing home or patented Sing log home; We guaranteed Sing building technology is the easiest way to build any insulated, lightweight, high-strength and Eco-friendly structure.

Keep your personal items free from mold mildew

2 Mold and Mildew Free for 50 Years Guarantee

No other shed will offer you this critical guarantee.

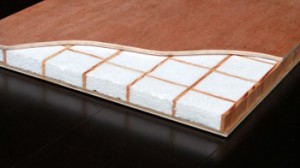

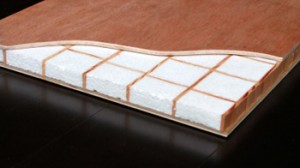

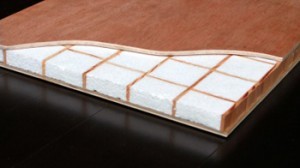

The Reinforced Structural Insulated Panels have built-in insulation that protects your precious belongings so that you don’t have to worry about unnecessary exposure to mold and/or mildew making Sing RSIPs the best solution for safeguarding the storage of perishables including moisture sensitive items like photos, books and magazines. See: Comparison to other materials

Imagine building a do it yourself insulated shed quickly without heavy equipment or tools and having the safest and most secure environment for storage of your items that you want to be protected from mold and mildew.

There are several Sing portable storage units at our factory site. None of them have any moisture condensation which is the main cause of mold and mildew. This is the reason we guarantee any storage building made of Sing floor, Sing wall and sing roof will be free of mold and mildew for 50 years if structured correctly without any water leak (make sure to seal all the corners and joining of two panels).

3 What You Will Need

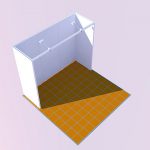

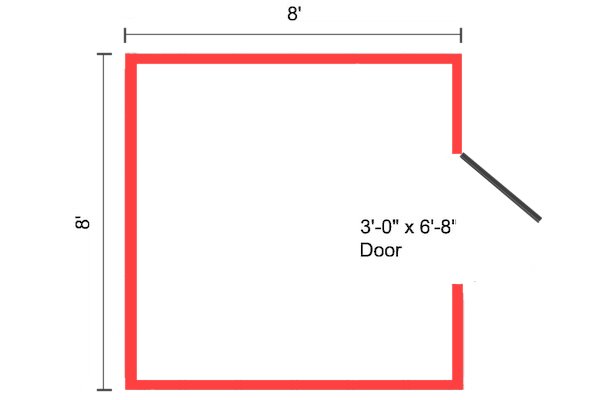

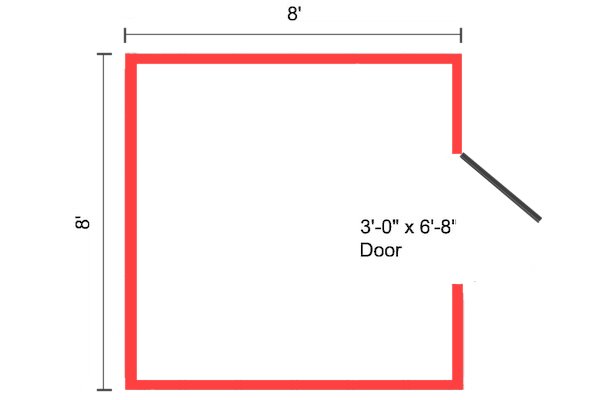

You will need a basic concept of your shed’s design starting with a floor plan layout drawing, like this:

1 Insulated Sing Sandwich Panels

Then count up the number of 4 ft. x 8 ft. x 1.5 in. insulated Sing Sandwich panels. In the example (above) you might opt for 8 panels for the walls, 4 for the floors (double-layered for a 3 inch insulated floor) and 2 more for the roof; for a total of 14 insulated Sing Sandwich panels.

2 Exterior Roofing Material

Next up you will need to decide what kind of roofing material you are going to use on your shed.

3 Exterior Siding and/or Finish

You will also need to determine what finish or siding your shed will have on it.

4 Accessories

You will probably need a way to get in and out of your insulated shed and you might enjoy a view.

Do you want to make your own door our of the Sing Sandwich remnant? (The part that was cut out for door placement.) or would you rather buy a door that is already pre-hung.

5 Connection Method

How will you connect your Sing Sandwich panels? There are many ways to connect your Sing Sandwich panels. See: Build a Wall for wall panel ideas for how to connect walls.

It’s as Easy as That

Now, you have everything you need to build your insulated shed in a few hours.

Finding Someone to Build Your Insulated Shed

What if you want an insulated shed but don’t have the skills that it takes to build an insulated shed? No problem. Here are some ideas for getting your DIY insulated shed built so you don’t have to).

1 Hire a Contractor

Of course having your contractor, one that you know and trust, would be the first choice but there are other methods, also.

2 Hire a Handyman

Almost any handyman, wood worker, even a landscaper likely has the tools and skill necessary to build your insulated shed for you.

3. Temporary Agency

A local temporary service agency, like Labor Ready, may have someone with the skills necessary to build your insulated shed for you.

4. Check the Parking Lot

You might be surprised to find competent local contractors and day laborers standing alongside their work trucks outside the local hardware store parking lot as they are getting their materials for their day’s work. This gives you the opportunity to meet them face-to-face to decide whether they are a good match for your project or not.

Do it Yourself Insulated Shed

Do it Yourself Insulated Shed

Homeowners and builders who are likely not to settle for anything less than the very best will seek out Sing sandwich panels including their next insulated shed.

The Pacific Northwest is the home of Sing Core and in this wet and wild part of the United States we know how critical it can be to maintain a moisture-free environment for either short term or long term storage; the last thing that you want to do it to put your belongings at risk by exposure to mold or mildew.

What’s Next After I’ve Build My Own Insulated Shed?

After you’ve built your own insulated shed quickly it is so easy to take your following project to the next logical level and take the journey to build other lightweight, high strength insulated structures.

4 Build Almost Anything with Patented Sing Building Materials

If you can build a Sing storage shed then you could easily also build a Sing tiny house.

How Do I get Sing Products?

For more information, see: Pricing

If you can build a Sing tiny house then you could easily also build a large Sing insulated panel house. You can even build a large structure without requiring a permit in certain cities and counties (make sure to check with your local building codes).

If you can build a Sing insulated panel house then you could easily also build a patented Sing log home. The best log home in the world. Using patented perfectly straight insulated Sing logs without any cracks, checks, twisting or shrinkage.

There are endless applications that you could build by using Sing Sandwich panels and Sing Panels.

Sing Sheds

Sing Tiny House

Sing Home

1 Perfect Modular Sliding Door VWS 72×80

1 Perfect Modular Sliding Door VWS 72×80 1 Perfect Modular Sliding Door APG 72×80

1 Perfect Modular Sliding Door APG 72×80