Custom Whiteboard Panels, Large Whiteboard Panels, and Lightweight Whiteboard Panels

Custom Whiteboard Panels by Sing Core. At Sing Core, we make it simple for you to create whiteboards that are exactly what you need. Whether you are designing a workspace, a classroom, or a high-end office, our Lightweight Whiteboard Panels and Large Whiteboard Panels give you unmatched flexibility, strength, and style. We empower architects, designers, and businesses to build the boards they want, in any size, format, or style, without compromising performance or appearance.

Custom Whiteboard Panels of any Size

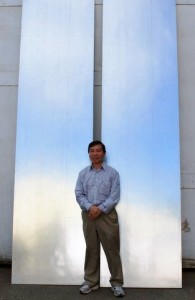

When it comes to whiteboards, size matters. Sometimes, you need a small wall-mounted board. Other times, you need a giant board spanning 20 feet or more. Sing Core allows you to order Custom Whiteboard Panels in virtually any size—up to 50 feet in length.

With our panels, installation is easy. You can mount them on walls, suspend them from ceilings, or even make portable, free-standing units. Because our boards are lightweight, moving and adjusting them is quick and effortless. This freedom ensures that your project—or your client’s project—can be executed exactly as envisioned, without the usual challenges of handling oversized, heavy boards.

Lightweight but Unmatched Strength

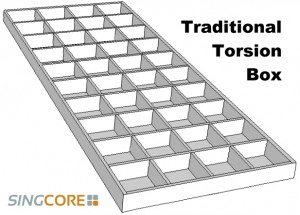

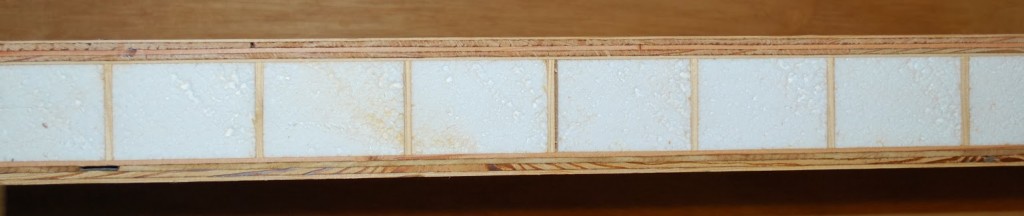

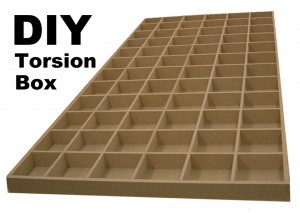

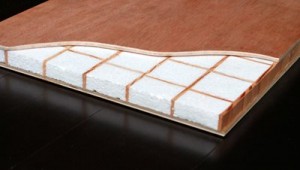

A common issue with large whiteboards is that they can warp or sag over time. Traditional boards, especially oversized ones, require heavy support and careful handling. Sing Core eliminates this problem. Our patented internal structure provides exceptional strength while remaining extremely lightweight. This means your Large Whiteboard Panels are strong, stable, and anti-warp—perfect for both commercial and residential use.

Even our largest boards remain manageable, saving time, labor, and installation costs. Architects and designers especially appreciate this feature, as it allows them to incorporate expansive whiteboard surfaces into innovative designs without compromising structural integrity.

Order your Custom Whiteboard Panel TODAY

If you’re planning a Custom Whiteboard Panel or any other specialty door project, now is the perfect time to get a fast, accurate quote. Visit our estimate page at singcore.com/pricing-3/get-an-estimate and tell us what you’re building. We’ll review your project details and provide a personalized estimate so you can move forward with confidence. Let Sing Core help you create a lightweight, strong, and warp-free solution built just for you. CLICK HERE

Magnetic and Multi-Functional Options

Sing Core doesn’t just stop at standard whiteboards. We also offer magnetic whiteboards, magnetic chalkboards, and multifunction panels that combine several uses in one. For example, you can have a sliding door that doubles as a whiteboard, allowing you to write, display, and hang documents—all on a single surface.

These multifunction panels open the door to limitless possibilities. You can attach glass, D514 laminate, or other dry erase surfaces to create a board that works exactly the way you want it. The result is a workspace that is efficient, flexible, and visually stunning.

Eco-Friendly and Long-Lasting

At Sing Core, we care about sustainability. Our Lightweight Whiteboard Panels are made from eco-friendly materials, combining high-performance design with environmental responsibility. Unlike conventional whiteboards that rely on heavy metals or unsustainable materials, our panels are lightweight, renewable, and durable.

We back every Sing Core panel with a limited lifetime guarantee, giving you confidence that your investment will last. When you choose Sing Core, you choose a product that is built to perform, built to last, and built with the planet in mind.

Easy Installation and Handling of Custom Whiteboard Panels

Because our boards are lightweight, installation is easier than ever. Wall mounting, free-standing setups, or portable whiteboards all become simple tasks. Even our Large Whiteboard Panels can be moved, installed, or removed with minimal effort.

Transitioning between different applications is effortless. Whether you are switching from a magnetic panel to a chalkboard panel, or installing a custom sliding door whiteboard, Sing Core ensures that the process is smooth and hassle-free.

Custom Whiteboard Panels Made Simple

Our solutions aren’t just practical—they are beautiful. Sing Core panels provide a sleek, professional look while maintaining superior performance. Architects and designers appreciate that our boards integrate seamlessly into high-end interiors, modern offices, and creative workspaces.

In addition, our patented internal structure allows us to keep panels lightweight without sacrificing strength. This makes it possible to create expansive, uninterrupted surfaces that are anti-warp, stable, and reliable, even in demanding environments.

Unlimited Innovation and Customization

One of the most exciting aspects of Sing Core is the endless potential for customization. Our panels can be tailored to any need, including:

-

Wall-mounted, portable, or free-standing designs

-

Framed or unframed options

-

Double-sided or reversible surfaces

-

Magnetic or non-magnetic applications

-

Specialty surfaces like D514 laminate, glass, or chalkboard

This flexibility makes our whiteboards ideal for offices, schools, creative studios, and any project that demands something beyond the standard options. Our team works with you to design a solution that matches your vision, without compromise.

Why Choose Sing Core’s Custom Whiteboard Panels?

The difference lies in what’s inside. Sing Core’s patented core technology provides world-class strength, stability, and longevity. Our whiteboards are not just functional—they are innovative, lightweight, and eco-friendly.

Compared to traditional boards, Sing Core panels resist warping, maintain flatness over time, and remain easy to handle. Our magnetic options hold notes and documents securely, while our multi-functional panels offer versatile applications that go beyond writing and erasing.

With Sing Core, you don’t have to choose between performance and ease of use. You get both, every time.

Applications for Sing Core

Sing Core whiteboards and multifunction panels can serve a variety of purposes, including:

-

Office environments: Writable walls, portable brainstorming boards, magnetic project boards.

-

Education: Classrooms, lecture halls, and laboratories with large writable surfaces.

-

Design studios: Custom panels for drawing, planning, and collaborative work.

-

Hospitality and residential: Sliding door whiteboards, kitchen or family command centers, and stylish, functional wall features.

No matter the application, Sing Core makes it possible to have exactly the right size, strength, and function for your project.

World-Class Custom Whiteboard Panels Innovation

At Sing Core, we believe in creating products that make life easier while enhancing design possibilities. Our Lightweight Whiteboard Panels, Large Whiteboard Panels, and Custom Whiteboard Panels are more than just functional—they are a world-class invention.

From eco-friendly materials to patented internal structures, our panels represent the best in lightweight, strong, and stable whiteboard technology. They can be customized, mounted, transported, and used in ways that traditional whiteboards simply cannot match.

Order your Custom Whiteboard Panels

In conclusion, Sing Core gives you tools, technology, & expertise. Whether you are designing a small portable panel or a massive 50-foot writable wall, Sing Core is the answer. Explore the possibilities. Discover the innovations. See why clients trust us for Custom Whiteboard Panels that are strong, lightweight, and versatile.

With Sing Core, anything is possible. From magnetic boards to chalk surfaces, from sliding doors to large office panels, your Lightweight Whiteboard Panels will never warp, sag, or limit your creativity. Order HERE Today!

See more Sing Core Products

Want to see other Sing Core Products, checkout our Large Sliding Doors HERE.