- Insulated sound dampening

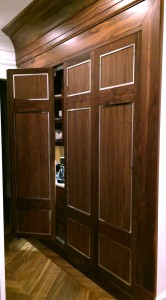

- Sound deadening sandwich doors

- Sing panel for sound deadening rooms

- Over-sized sound dampening lightweight door

- Big lightweight honeycomb door panel

- Large honeycomb deadening panels

- Lightweight honeycomb panels

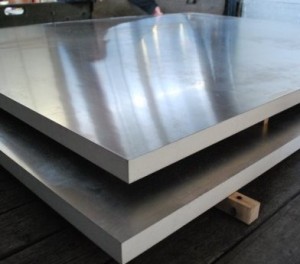

Sing Stainless Steel

Sing Stainless Steel is stronger than plain stainless steel, but has the advantage of being extremely lightweight and eco-friendly. Sing Stainless Steel retains all the structural integrity of solid steel… even exceeds over long spans and is one of the most popular members of our Sing Metal family.

Sing Stainless Steel is stronger than plain stainless steel, but has the advantage of being extremely lightweight and eco-friendly. Sing Stainless Steel retains all the structural integrity of solid steel… even exceeds over long spans and is one of the most popular members of our Sing Metal family.

Most popular Sing Staninless Steel product is the

Sing Stainless Steel Panel

The standard Sing Stainless Steel Panel size is 4 ft x 8 ft panels that are one inch thick as insulated wall panels with steel exteriors. Though Sing Stainless Steel Panels are completely customizable, our standard panels come with embedded solid wood edges for easy assembly and are available in almost any length, width and thickness. Feel free to get the panels that you want with the specifications that you desire without loss of structural integrity in sizes up to 50 feet.

These extremely lightweight panels easy to connect and physically maneuver without extra heavy equipment and are ideal for applications in any length, width or thickness. The steel surface is very easy to clean and resists the harsh chemicals often used to sanitize cleanrooms and other environmental enclosures.

Applications:

Next up in popularity is the

Sing Stainless Steel Post and Beam

The Sing Stainless Steel posts and beams are used both structurally, for beautification and in exterior environments.

Standard sizes of Sing Stainless Steel posts and beams:

Advantages of Sing Stainless Steel over standard solid stainless steel:

Eco-friendly Sing Stainless Steel realizes substantial reductions in:

See also out top-selling Sing Steel Door

One of the greatest attributes of your sliding door is the actual sliding performance of the sliding door, especially closet doors. See our new C Series line of Affordable Barn Door and Sliding Closet Doors.

Certainly, upon installation, your wood sliding door or interior pocket doors may perform superbly… but for how long?

It may be important for you to seek out how to make a sliding door that has a high level of performance. And what are the benefits that will increase the performance of your sliding door? Consider:

| 1. | True flat | straight and will stay flat |

| 2. | Lightweight | 1/3 the weight (or more) |

| 3. | High strength | stronger than steel lb. for lb. |

| 4. | Insulated | starting at R3 |

| 5. | Sound-deadening | starting at SCT 30 |

| 6. | Resistant to warp, twist & rot | to meet your specifications |

| 7. | Longevity | built to last for centuries |

| 8. | Guaranteed | 10 to 50 year guarantee |

| 9. | Eco-friendly | sustainable true green technology |

Only one door company can deliver a sliding door that delivers high marks in all those important features. See our comparison chart comparing Sing Core doors panels to other door core materials.

So if you’re looking for closet ideas, sliding closet doors or double closet doors for your wardrobes that are true flat and stay flat without warping or twisting, then you might consider the Sing Core alternative.

So if you’re looking for closet ideas, sliding closet doors or double closet doors for your wardrobes that are true flat and stay flat without warping or twisting, then you might consider the Sing Core alternative.

Our industrial sliding doors and marine sliding doors are specially designed to survive the rigorous changes in the elements including exposure to extreme weather conditions.

The secret lies within the core of the sliding door which is basically one of our honeycomb panels (which is also available in aluminum honeycomb panels) that is the foundation for the superior performance of sliding doors that must remain perfectly straight to reduce maintenance over time.

Even though any Sing sliding door can be finished in any flat exterior building material, the aluminum sliding door is extremely popular and can easily have any other surface material, like any wood species, concrete, glass, FRP, HPL, and can be made to be water-resistant or bullet-proof.

The Sing sliding door is not only a light door that reduces strain and wear on the door hardware, but it is also stronger than metal hanging sliding doors and even make magnificent plastic sliding doors.

And when it comes to big sliding doors, our custom oversize sliding doors continue to deliver the best results enjoyed by the top millworks and door companies in the world service the most demanding high-end users.

Sing Core provides architects, designers, contractors and commercial industries a new, Eco-friendly alternative to traditional metal fabrication that is lightweight and stronger than metal.

Sing Core provides architects, designers, contractors and commercial industries a new, Eco-friendly alternative to traditional metal fabrication that is lightweight and stronger than metal.

Now only $256 for a 4’x8′ sheet.

| Size | Sqft | Price |

|---|---|---|

| 4’x8′ | 32sqft | $256/sheet |

| 4’x10′ | 40sqft | $320/sheet |

| over 4’x10′ | any size | Ask for price |

If you have a special custom, architecturally specified, or otherwise unique requirement for your project, don’t hesitate to ask. We are experts in the unexpected, and seek to exceed your every desire. Visit our pricing page for more information and to submit your price quote request.

Known for the most prestigious wooden panels for walls and doors, Sing Core material panels offer outstanding solutions for the most challenging composite structures.

When compared to other types of composite materials, our lightweight wood panels outperform any china panel or panels of wood based product.

Each custom panel features our unique patented honeycomb core that can host any exterior surface material for a lightweight composite structural panel, including (but not limited to) aluminum metal or any flat metal.

Lightweight aluminum composite panels are the second-most best selling product that Sing Core makes with high precision and performance that cannot be matched by the standard aluminum shop. Our light weight aluminum and honeycomb composite is the perfect component available in nearly any aluminum thickness for use in aluminum structures.

Next up, our galvanized metal panels are equally as popular as our Sing Core aluminum that exceeds any machine aluminum strength while remaining lightweight and true flat. This is the only aluminum material that can be perfectly flat and stay flat over long spans for years.

If you are ready to take your aluminum design to the next level, Sing aluminum metal products are worth investigating in your best interest, for the benefit of your clients and a better world.