Q: Are Sing museum display panels nailable?

A: Sing museum display panels are nailable if the skin is over 1/4 inch plywood or custom nailing block or strips are pre-planted prior to manufacture. Our standard surface material is plywood. It may be important, if you are specifying a special exterior skin or other specifications, to note in advance to the manufacture of your panels that you intend to nail, as that may require additional material to accommodate nailing.

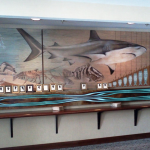

Q: What does a standard Museum Wall Panel look like?

A: Sing Museum Wall panels are created to any specs supplied by the museum’s architectural designer. The base Museum Wall Panel is 4 ft. x 8 ft. x 3 in. with 3/8 inch MDF surfaces, though 1/4 inch Marine Grade plywood is also in demand as a base material. Though these are fairly standard, your panels can be completely customized to your specs.

Q: Do your Museum Wall Panels come with Cam Locks?

A: Sing Museum Wall panels can have cam locks installed at an additional charge. In most cases, museums order the panels without alterations as the staff woodcrafts people install cam lock on-site. In some cases it is requested that panels are pre-drilled for cam locks or have cam locks installed at an additional charge.

Q: How thick can your Museum Wall Panels be?

A: Sing Museum Wall panels can be any thickness that you are considering for your museum exhibit design. It is common for our museum clients to order extra thick panels (normally 6 inches thick, but could be thicker), so that they can be assembled singlehandedly (yes, they are that light weight) and without having to secure them (standing solitarily) very stable.

Q: Can the appearance of your museum display panels be changed on-site?

A: All standard Sing museum display panels are compatible with vinyl covering materials that are widely available in almost any color, design and may be custom printed. These self-adhesive vinyl sheets (also available in rolls) can be applied and changed at any time within minutes.

Q: Do your museum display panels require complicated, patented hardware that costs extra?

A: Our standard museum display panels have built-in solid wood edging and wood panel facings that can easily be assembled with basic woodworking skills and tools. We do have connection systems available for our clients, if requested, also we can retrofit our Sing panels to fit any existing hardware that you may be currently using.

Q: Do your museum display panels have electrical channels built-in?

A: Our standard museum display panels do not come with interior electrical channels, we do provide then either vertically or horizontally to your specifications at an additional charge. Many millworks router-out their own channels for wire management from the basic Sing panel’s solid wood edging.

Q: Do your museum display panels have headers to support lighting attachments?

A: Standard Sing museum display panels are strong enough to support lighting, shelving and accessory attachments without adding any additional support. Simply attach your gear just like you would any standard framed wall. (No expensive proprietary hardware attachments necessary.)

Q: What if we need to reconfigure your museum display panels? Will we have to buy special hardware or seek out a metal shop?

A: Standard Sing museum display panels are wood, unless your specifications require other materials to be used, so any panels can be easily redesigned reconfigured with basic carpentry skills and standard woodworking tools.

Q: What finishes do you have available for your museum display panels?

A: All Sing trade show panels are available in virtually any surface material that you desire. Standard paint grade panels can be painted and finished, or re-painted and re-finished just like any other wood-based wall. Otherwise, peel and stick vinyl coverings are available in nearly any color imaginable and easy to cover to accommodate any desired appearance on-the-fly.

Q: Do you have end caps, or trim available for your museum display walls?

A: Basically, we do not engage in the finish work of your walls, though we can complete the entire design at additional cost. Most of our clients save the money and do the finish work themselves and wood trim is a simple and elegant enhancement for your Sing museum display walls.

Q: Where can we get parts and accessories for your museum display panels?

A: Since our basic Sing museum display panels are wood-base, unlike other expensive patented import wall systems, no special hardware is necessary. Anything you need is easily attainable from your local hardware store, or available through online retailers like eBay or Amazon.