- High precision workstations

- Retail office furnishings

- Exterior Equipment Enclosures

- Extreme Weather Protection

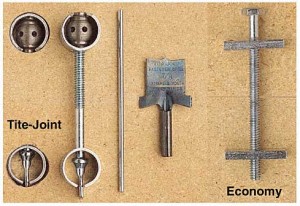

With the wide variety of applications for Sing Core panels, posts and beams, and equally diverse selection of fasteners are used in practical installations.

Here are some of the most popular fastening systems used today:

Here are some of the most popular fastening systems used today:

Norse Inc. Latches

Norse latches are designed for concealed installation in Sing Panels. Multiple configurations of latches and receivers are possible to suit many applications, and offer numerous advantages.

Click Here for More Information …

Knape & Vogt Manufacturing Company

More than a century of experience to the design, manufacturing and distribution of functional hardware, storage-related components, and ergonomic products for original equipment manufacturers of the Tite Joint Fastener Draw Bolt.

More than a century of experience to the design, manufacturing and distribution of functional hardware, storage-related components, and ergonomic products for original equipment manufacturers of the Tite Joint Fastener Draw Bolt.

Click Here for More Information …

Pan American Screw

An International leader of innovative threaded fastening solutions. Developers of the Draw Bolts and Zipbolt™ tight joint fasteners. They are constantly testing and developing fasteners that are easier, faster and less costly to use.

Click Here for More Information …

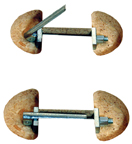

FastCap

Over the past five years, FastCap has grown exponentially and has expanded its products base from the Fastcap to a vast array of woodworking products and tools, like the FlipBolt Tite-Joint Dog Bone Fastener Tool-less Draw Bolt.

Over the past five years, FastCap has grown exponentially and has expanded its products base from the Fastcap to a vast array of woodworking products and tools, like the FlipBolt Tite-Joint Dog Bone Fastener Tool-less Draw Bolt.

Click Here for More Information …

ITW Fastex

The range of panel fasteners and plastic clips available from ITW Fastex is designed to fill most fastening requirements. The range of applications is wide from machines, appliances, and computers to recreational vehicles and point of purchase displays.

Click Here for More Information …

Shur-Lok fasteners and components are designed to satisfy customer requirements in two general application ideas: secondary structures, such as interior stow bins, lavatories and galleys, and primary structures, such as aircraft engines, engine pylons, landing gears, wings, gearboxes, transmissions and helicopter rotors–all critical applications.

Click Here for More Information …

Veck Fasteners

Special and bespoke bonding fasteners. In addition to Veck Fasteners standard range of popular bonding fasteners, we provide purpose-designed special and bespoke bonding fasteners for customers who have specific requirements which cannot be fulfilled from our standard range.

Click Here for More Information …

Just to name a few..

Sing Core’s Metal Fabrication Department is shaking up the industry!

Sing Core’s Metal Fabrication Department is shaking up the industry!

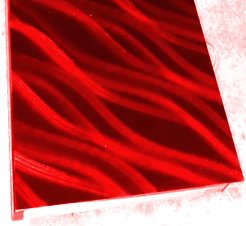

Our new applications are changing how to fabricate metal panels: Don’t’ Get Framed! One of our clients, I-5 Designs, has us expanding our capabilities to meet the increased demand for the longest, most beautiful aluminum panels that are eco-friendly, lightweight and stronger than steel.

Traditional metal fabricated panels expend excessive energy in their creation, using aluminum framing and the result is a panel that looks acceptable but has no strength.

This is extremely advantageous when maintaining structural integrity over long spans… Check out this page on our web site: . You will see these 37 foot long beautiful ruby red aluminum panels that we are so proud of. Lightweight, eco-friendly, superior strength and gorgeous; you must see it to believe it.

1-2 Sing Core vs. Other Cores

1-2 Sing Core vs. Other CoresCompared to other material Sing Core is possibly the most significant Eco-friendly, renewable structural advancement in the last century increasing the strength and reducing the weight of any solid structural material.

When compared to solid material, Sing Core:

The conclusions in the following chart are based on our independent analysis. If you do not agree with any comparison results, please let us know. If you agree that these conclusions are accurate, please share this with your friends to help us build a better, more sustainable world. |

Sing Core Comparisons Based on 2″ x 2″ Grids

| Sing Core | Foam | Aluminum | Balsawood | Nomex | Plastic | Cardboard | |

| Insulation | ✓ | ✓ | x | x | x | x | x |

| Sound Deadening | ✓ | ✓ | x | x | x | x | x |

| Lightweight | ✓ | ✓ | ✓ | ✓ | ✓ | x | x |

| Strength | ✓ | x | ✓ | ✓ | ✓ | x | x |

| Solid | ✓ | ✓ | x | ✓ | x | x | x |

| Eco-friendly | ✓ | x | x | ✓ | x | x | ✓ |

| Renewable | ✓ | x | x | ✓ | x | x | ✓ |

| Oversize | ✓ | x | x | x | x | x | x |

| Dimensionally Stable | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Affordable | ✓ | x | x | x | x | x | ✓ |

| Waterproof Upgrade? | ✓ | ✓ | ✓ | x | ✓ | ✓ | x |

| Fire Retardant Upgrade? | ✓ | ✓ | ✓ | ✓ | ✓ | x | ✓ |

| Bullet-proof Upgrade | ✓ | ✓ | x | x | x | x | x |

| Thickness Available | ✓ | x | x | x | x | x | x |

| Skin Options | ✓ | x | x | x | x | x | x |

| Easy to Machine | ✓ | x | x | x | x | x | x |

| Fast Turnaround | ✓ | x | x | x | x | x | x |

Insulation: Sing Core has built-in insulation value with an R3 to R6.5 rating per inch, depending on client’s needs/specifications.

Sound deadening: Sing Core’s filler material has natural sound-deadening properties. Other sound-deadening options are available at customer request.

Light weight: When compared to other materials Sing Core weighs much less, as much as 50% less, or more, as little as 4 lbs. per sq. ft. yet eco-friendly. This advanced technology used in the aviation industry is now available for use in your home.

Strength: Sing Core based on 2″ x 2″ grids and 3/4″ thick = 660 PSI. For instance, aluminum 3/8″ grids = 30+ PSI (smaller grids should be more strength). Sing Core’s superior strength comes from its advanced torsion box design.

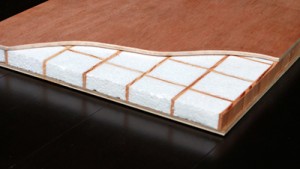

Solid: Sing Core is solid like a rock. While the vertical wood grain torsion box core may be compared to other hollow honeycomb cores, the Sing Core voids are not hollow as they are bonded wall-to-wall and filled with recycled foam for a strong, solid substrate.

Eco-friendly: Sing Core is manufactured using natural wood fibers, no formaldehyde, or toxic chemicals, is created using less energy than any other core material with little or no waste.

Renewable: The structure of Sing Core is 100% renewable (nature-grown) clean fiber and/or recycled material.

Oversize: Sing Core excels in area of large oversize products due to its unique properties and can be up to 50 foot length.

Dimensionally stable: Sing Core is the most dimensionally stable building material allowing us to create large, oversize products (i.e., doors, up to 50 ft.) that are true flat exceeding AWI standards and can be guaranteed to be true flat. Large oversize panels can be truly dimensionally stable without any movement due to temperature and moisture change.

Thickness available: Sing Core is readily available in many thicknesses, up to 6 inches in standard thickness, with custom thicknesses available.

Skin options: Available in many different exteriors including (but not limited to) aluminum, cement board, cold roll steel, concrete, ceramic tile, fiber glass, galvanize metal, glass, MDF, metal, plastic, plywood, solid wood, stainless steel, etc…

Easy to machine: Sing Core is easy to work with in the shop or on-site for sawing, sanding, adding solid wood implants, gluing, cutting and fastening.

Fast turnaround: In you’re in a rush, only Sing Core can be custom made within 24 hours and is proudly manufactured for you in the USA.

Even though Sing Core is less expensive than most solid material, the end result is more structurally sound, lightweight, will not compromise over time and reduces the amount of man-hours and equipment to install.

Sing Core is a honeycomb sandwich panel composite material with built in structural grids. Sing Core could have the exterior surface skin of any material including, but not limited to wood (seen in photo), metal, plastic, glass, Kevlar, even concrete and cement. The strength of our design is due to the structural grids made of naturally abundant, renewable, vertical grain veneer wood fiber. Sing Core is constructed in a fashion similar to torsion box technology most commonly found in the aeronautics and space exploration industries.

This technology is what allows our panels remain strong, lightweight, and flat without denting, cracking, and warping. See a comparison here. Inventor Peter Sing uses this torsion box technology, along with wood fiber and foam to create patented Sing honeycomb core: the incredibly strong, true flat, lightweight, renewable composite material of the future. Check out our products section to see a few different applications.

Engineering Myth-busters

Most construction is a waste of materials, natural resources and has a negative impact on our planet. Solid materials are overused in an attempt to increase the strength or lifespan of the project. This excess of materials and resources is not necessary… and can be likened to killing a fly with a machine gun.

It may be hard to believe, at first, but for the first time in our history, a truly responsible structural alternative can be found in Sing Core technology. Many of our clients were skeptical when they queried us about our lightweight and strong solutions to their design challenges.

That is why Sing Core is the secret ingredient found in the homes, offices, estates and showrooms of royalty, political and religious high-end environments. Once you try the Sing Core alternative, you will never go back to traditional building materials in some cases.

Traditional honeycomb panels have come to the rescue addressing the lightweight needs of industry. Sing Core is compatible to (if not well out-performing) most honeycomb technology in terms of weight, but no other honeycomb core can compare to Sing Core in terms of strength. None.

Before today, you did not know about Sing Core’s environmentally responsible solutions to function and sustainability. Now that you do, what will you do with that knowledge?

Take the Sing Core challenge.

Aluminum Composite Panels

Aluminum Composite PanelsAdvantange of Sing Aluminum Composite Panels vs. Other Aluminum Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio | Eco-friendly | |

| Sing Aluminum Panel | Y | Y | Y | Y | Y |

| Solid Aluminum | N | N | N | N | N |

| Aluminum Honeycomb | N | N | N | N | N |

Easy to close edge, edge banding, install solid wood implant at any location which provide stronger bonding Case study. Aluminum out door bench. Veneer face aluminum door. The longest, strongest, lightweight eco-friendly 37 ft x 3 ft aluminum panels shipped from Seattle to New York

Easy to close edge, edge banding, install solid wood implant at any location which provide stronger bonding Case study. Aluminum out door bench. Veneer face aluminum door. The longest, strongest, lightweight eco-friendly 37 ft x 3 ft aluminum panels shipped from Seattle to New York

|

|

Sing Honeycomb Metal Panels are stronger and lighter than other metal panels, which can be dented by something as small as a golf ball. The torsion box core holds the Sing Metal Panel flat so that it will not warp and sag. A 16lb steel hammer will easily dent a steel or vinyl door, but not a Sing Metal Panel. Because Sing panels are efficient to produce, they are more affordable than solid steel panels.

Advantange of Sing Metal Panels vs. Other Metal Panels

| Sound Deadening | Insulated | Lightweight? | Strength to Weight Ratio | Eco-friendly | |

| Sing Metal Panel | Y | Y | Y | Y | Y |

| Solid Metal | N | N | N | N | N |

| Metal Honeycomb | N | N | N | N | N |

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features. Sing Core Cold Rolled Steel Panels have a wide range of applications, are not limited in length or width and though we excel in large projects, we also provide solutions for reduced dimesions for smaller projects. The example to the left is an application that was used in material handling. This trough is constructed with 20 gauge cold rolled steel and is used for moving raw material. The image to the right is an example of a cut out that was made in the trough. These are just a few examples of how Sing Core Cold Rolled Steel Panels are flexible and easy to use in a variety of applications. See also Sing Core Metal and Sing Cold Rolled Steel Panels

Sing Core patented honeycomb core is combined with steel skins into a well balanced material system. Outstandingly low weight of this solution compared to any solid metal sheet is just one of the product features. Sing Core Cold Rolled Steel Panels have a wide range of applications, are not limited in length or width and though we excel in large projects, we also provide solutions for reduced dimesions for smaller projects. The example to the left is an application that was used in material handling. This trough is constructed with 20 gauge cold rolled steel and is used for moving raw material. The image to the right is an example of a cut out that was made in the trough. These are just a few examples of how Sing Core Cold Rolled Steel Panels are flexible and easy to use in a variety of applications. See also Sing Core Metal and Sing Cold Rolled Steel Panels

Specialty Panels

Specialty PanelsSing Core offers a wide range of sizes. Getting a quote for your specialty product, is easy, thanks to our simple online order system. All we need to know is the length, width, thickness and what you desire on the exterior, and your custom specialty panels are made to order. If you’re looking for a bargain price, remember, the more you order, the less expensive your total order will be per piece. Quantitiy and wholesale inquiries are encouraged. Feel free to contact us for more information.

True Flat for Perfectly Straight High Performance

True Flat for Perfectly Straight High Performance

When our clients will not settle for second-best, they rely on our expertise in making true flat sliding doors that are perfectly straight for high performance to satisfy the most demanding applications.

Big sliding doors present challenges because the slightest warp, twist or cupping can not only affect the performance, but possibly more importantly, any deflection will be noticeable in the gap between the door and the wall.

In most cases, nearly any sliding door will appear to be straight upon installation, but only Sing Core sliding doors can maintain their true flat integrity for centuries and are guaranteed for up to 50 years.

When it makes sense to seek out only the best tried and true flat solution in sliding door technology regardless of size, you will agree with our clients that Sing Core is the only solution (see testimonial).

Big Sliding Doors

Sing Core is the secret ingredient inside our large, oversize sliding doors and other large doors that are true flat, eco-friendly and built to last.

If you are looking for a large sliding door solution that gives you the Sing Core sliding door advantages, like light weight, superior strength, long life and flat, then you’ve come to the right place. Just let us know your expectations and based on our expertise, we will be able to provide you with a solution that we can guarantee.

Sing Core big sliding doors are not only revolutionary in their design, but each huge sliding door helps to make the world a better place. With our commitment to sustainability you can have an American-made, eco-friendly large oversize sliding door that will last the test of time.

For the last few years, this emerging aerospace technology has been providing solutions to architects and designers that is top drawer, to say the least. The best-known, oldest, most reliable, high-end millworks in the

United States depend on Sing Core to deliver the goods for them when it comes to large, oversize sliding doors.

This technology is solving large oversize sliding door design solutions for Presidents, Prime Ministers, Kings and the Pope, especially when the application calls for extra strength, oversize or true flat… without compromising weight for strength.

Sing Core is making this technology available to anyone who wants a large fashionable, lightweight sliding door, like:

Just to name a few. The beauty of the Sing Core large oversize sliding door technology is that your door can be made out of nearly of any exterior material that you can imagine and we can guarantee your big door to be true flat over long spans, and will not warp, twist or experience extreme deflection under stress. And, thanks to the lightweight properties in comparison to other solid materials available, Sing Core oversized doors though large in size, are lightweight, causing less strain on the structure and hardware. Sing Core doors are available in any height, any width, any thickness.

Some examples of materials that we have made sliding doors out of include:

… including ballistic materials for bulletproof applications. The possibilities are limited only to any available flat building material.

Sing Core Large Veneer Doors

As one of our high end options we offer the most appealing wood veneer doors for your enjoyment. With our special core and patented and patent pending methods, we supply exquisite hard wood veneer doors that appear just like solid wood, even when looking at our doors from the side. This allows you to achieve the beautiful look of solid wood while still maintaining the weight advantage of using our patented and patent pending core.

No one else can make a large veneer door like ours. Because of the warp free quality of our doors we can make them bigger, stronger, lighter in weight, and more warp free compared to other large veneer doors. Through our patented and patent pending methods, we have solve all of the problems with making large veneer doors to any specifications.

Versatility

Remember, Sing Core technology is completely customizable to your specifications as they are available in any length, any width and any thickness and bonded to any exterior finish.

We are so certain that Sing Core is the solution to your green building challenges that we offer a 100% refund for any prototype order, for those who want to test drive any form of Sing Core products for use in their applications, so you have nothing to lose. Click Here for our convenient online order form.

See also Sing Honeycomb Sliding and Pocket Doors, Sliding Patio and French Doors and Doors

install Sing panel, post and beam products are much easier than conventiaonl solid material. It is lighter in weight, high strength, true flat. It is safe for worker handle lightweight but sturdy material especially certain job site require heavy lifting, and hard to reach high rise work place.