Sing Core Aluminum Panels have a wide variety of applications.

Custom Sizes Available

If you have a special custom, architecturally specified, or otherwise unique requirement for your project, don’t hesitate to ask. We are experts in the unexpected, and seek to exceed your every desire. Visit our pricing page for more information and to submit your price quote request.

Sing’s aluminum wall panels are by far the strongest lightweight panels, and this is not your daddy’s aluminum panel, as Sing’s insulated aluminum panels are the highest precision and rated for both sound deadening and climate control aluminum composite panels available anywhere.

| Quite frankly, when most people think of using patented Sing Core aluminum honeycomb panels as solutions to their eco-friendly design challenges, they have something in particular in mind…In comparison to other aluminum honeycomb panels, sing core aluminum panels are lighter in weight, stronger than steel pound-for-pound and are “true green” building materials. Many people are surprised to find that sing core panels are used in such a wide variety of methods covering nearly every category of project design and development.

When your project demands lightweight, superior strength, and sustainability, Sing Core metal composites are the logical solution.

To the right, is a general list of just one of the many applications, where people have accepted the Sing Core challenge.

|

Aerospace Panels Aerostructure Panels Aircraft Panels Aluminum Canopies Aluminum Door Panels Aluminum Floors Aluminum Honeycomb Flooring Aluminum Shipping Containers Animal Housing Labs & Vivariums Balcony Panels Barricades Boat Decking Building panels Car Panels Clean Room Walls Ceiling Panels Cleanroom Panels Cleanrooms CMM Rooms Cold Storage Rooms Commercial Aircraft Flooring Computerized matte cutting tables Controlled & Critical Environments Cruise Ship Walls Curtain Walls Decking Digital X-Ray Systems Doors Elevator Walls Elevators Equipment Casings Equipment Enclosures  Ferry Walls Fixture Panels Fixturing Panels Flooring Furniture Panels Gangplanks Helicopter Rotor Blades Hurricane Panels* Impact Attenuation Panels Industrial Aluminum Panels Industrial Doors Inspection Rooms Interior and exterior cladding Laboratories Large Aluminum Hatches Laser Rooms Machine Components Machine Enclosures Manufacturing Cells Marine Panels Medical Panels Metrology Labs Mezzanine Panels Microelectronics Manufacturing  Military Aluminum Panels Motorsport Panels Moveable Floors and Covers Museum Panels Nano Technology Oil Mist Enclosures Packaging Rooms Paint Finishing Enclosures Paint System Enclosures Parts Storage & Control Pharmaceutical Packaging Plant Space Dividers Platforms Powder Coating Enclosures Racing Panels Railway Panels Ramp Panels Reflector Panels RV panels Satellite Panels Seating Panels Server Rooms Shelf Panels Shelters  Sidewalls Signage Panels Soffit Panels Solar Panels Space Panels Specialized Doors Sporting electronics Submarine Panels Storage Rooms Telescope Mirror Covers Temporary rooms Trailer Panels Treadplate Panels Truck/trailer doors Truck Panels Walk Ways and Platforms Wall Cladding Wall Coverings Wall Partitions Windmill Panels Yacht Walls |

Transportation – Ships, railcars, semitrailers, truck bodies, luxury yachts

|

Can be used inside transportation vehicles as raised floor, storage, or handling cargo.

Raised floor in van for handling cargo (see photos above)

- Sultan Reshid Baker

- Sports Jacuzzi Cover

- sing honeycomb lightweight corner of wood panel

- Ice Arena Deck

*Customer will need to perform lab tests to certify hurricane rating for local code compliance.

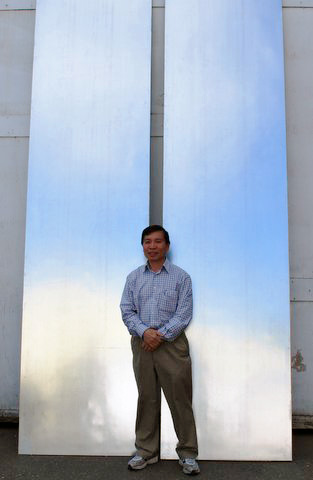

These SingCore 20 Guage Cold Rolled Steel Composite Panels measure 35″ x 13′ x 1″ are lightweight.

These SingCore 20 Guage Cold Rolled Steel Composite Panels measure 35″ x 13′ x 1″ are lightweight.

Sing Core Cold Rolled Steel Panels are incredibly lightweight and strong.

Sing Core Cold Rolled Steel Panels are incredibly lightweight and strong.