In the recent California State Fair, many artisans, purveyors and vendors from all walks of life were represented and the Fair, which is one of the top 20 state fairs in the United States of America, decided to showcase the works of the participating residents of California on Sing Trade Show Displays.

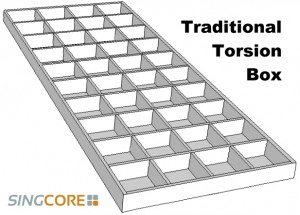

Unlike other, expensively imported wall panels, Sing Core trade show display panels, offer high end characteristics which are not available in the import wall panels. A closer look at the Sing trade show booths will reveal that while every Sing trade show panel may look just like any other trade show display panel, only Sing trade show displays feature panels with patented Sing Core inside.

One advantage of Sing trade show panels is that they can be custom manufactured in our factory in the Pacific Northwest by craftspeople that are proud to build your custom trade show displays, knowing it makes a difference to you to have faith that your best trade show displays are made in the USA.

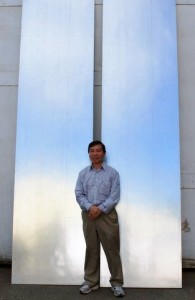

Since your Sing trade show booth can be customized, your individual panel size can be any size, up to or exceeding 20 ft. tall x 40 ft. long. The California State Fair took full advantage of the custom size option of the sing trade show display booth components. Rather than go with the standard sized trade show panel, they opted for custom 4×8 panels.

The full sized 4×8 panels were preferred to the smaller sized panels because the carpentry staff preferred the 4×8 size to cover more area quickly. Professional trade show panels are not generally available in such a large size doe to potential to warp, bend, twist of cup following set up, especially in a warm environment, like one would expect in California during the summer.

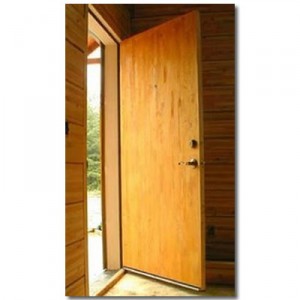

Other trade show panels fail due to warp, and if they are damaged, cannot be easily repaired, like a Sing Panel. Sing trade show panels are made to take a beating and still be able to be reused and made to look new again, year after year. That’s why they can come with a full 10-year guarantee against warping and full structure warranty.

Your investment with Sing Core is a safe one, backed by our face-to-face customer service.

Only one trade show panel could accomplish such feats, due to the nature of the embedded Sing Core technology inside.

Here are just some of the attributes you can enjoy from having Sing Core inside:

Lightweight Trade Show Booths

Lighter than any other Eco-friendly, lightweight, high strength panel known. Light weight makes them asy to assemble, even for the novice.

High Strength Trade Show Booths

Patented Sing Core is many times stronger than any other lightweight trade show panel, and has been independently tested at 660 PSI; that’s stronger than steel pound-for-pound.

Insulated Trade Show Booths

Fairs and trade show generate a lot of noise, the added benefit of having a solid, insulated sound-dampening structure helps to further offer additional separation between trade show booths.

Sustainable Trade Show Booths

Sing Eco-friendly trade show booths are made to be reused and repaired to original strength and appearance, not replaced, like other import display wall components.

Easy to Assemble Trade Show Booths

No need for a contractor to build your trade show display, if you’re using Sing modular trade show components which assembly easily without any special skills or tools required, except for an Allen wrench to secure the pre-installed cam locks.

10 Year Fail-free Guarantee

Sing trade show displays are the only ones that can be guaranteed not to fail for ten full years, including the panel’s structure.