Applications -> Building Components -> Assembly & Connecting

Connecting Panels

How to Build Gallery

There are many ways to join Sing Panels

Simple Joining

The simplest and least expensive way to join sing panels is to join in any way according to your budget and/or expertise.

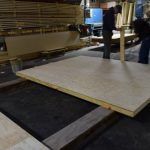

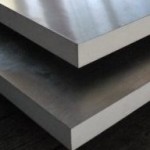

Due to Sing Panels being so straight and true it is easier to join panels together because they line up perfectly unlike other building materials.

In many cases, for instance, standard 4×8 panels can be nailed, glued or channel-joined quickly and easily with satisfactory results.

In many cases, for instance, standard 4×8 panels can be nailed, glued or channel-joined quickly and easily with satisfactory results.

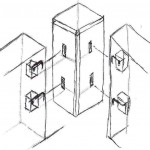

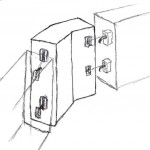

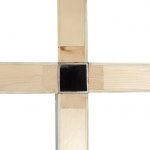

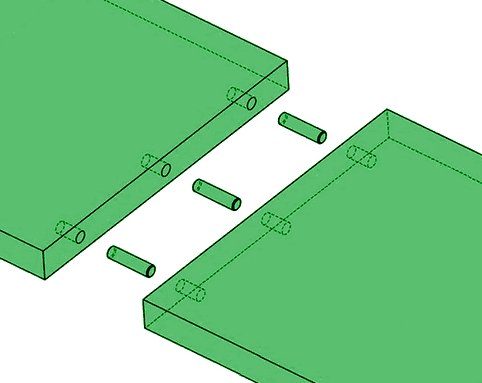

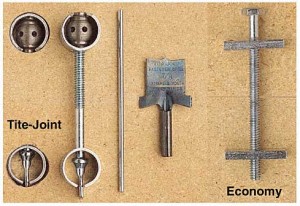

Other options for fastening panels may include cam locks (see examples left and right) that can be pre-installed, making assembly and joining easy and more secure.

- 4-way Connection

- X Connector

- Lightweight + Strong

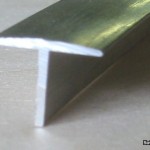

- L & T Connectors

- X Connector 4-way

- T Connectors

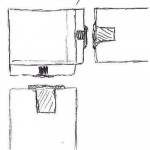

Thru-bolt Joining

One of the most inexpensive and secure ways to join sing panels is by utilizing a simple nut and bolt connection method, especially, if the panels will be routinely or repeatedly assembled and disassembled.

Stainless steel nuts and bolts offer the safety and security when joining sing panels.

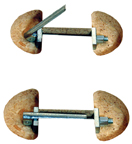

Biscuit Joining

In many cases, Sing Panels can be pre-configured for biscuit joining at your site of factory.

Especially for large projects, this enables Sing Core panels to be sent individually, reducing shipping and handling costs, for assembly at your facility or job site.

See images below for example of biscuit assembly of Sing Panels

- Biscuit

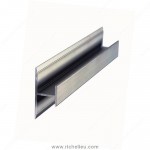

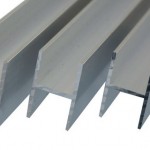

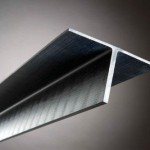

Joining With H Channel and H Molding

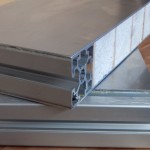

Embedded T-Slot Extruded Aluminum

In your choice of T1 (1 exposed slot) or T3 (3 exposed slots)

See: Sing T Slot Panels for more information.

Edge Banding

Unless specified Sing Panels do not ship edge-banded as 93% of our wholesale customers do their own edge-banding when finishing their Sing Panel.

Edge banding can take many forms from vinyl and plastic to wood and steel. Sing Panels are not intended for use as an un-banded product and may not qualify for our 50 year warranty if un-banded.

If your intention is to get the best, most long-lasting performance from your Sing Panels, feel free to take advantage of our free consultation to be guaranteed to achieve the results that you desire.

- Insulated metal roofing panels

Edge Banding Options Include:

T Molding

Here is an example of a large lightweight high-strength non-warping sliding door.

Here is an example of a large lightweight high-strength non-warping sliding door.

Note the steel T molding being installed to complete the door’s composition.

This door is guaranteed not to warp, bend, twist or otherwise fail due to being properly engineered and manufactured to exceed the specifications of this oversized architectural door.

T Molding

L Molding

Flat Molding

U Channel

Advanced Large Panels

Sing Core specializes in extremely large panels (up to 50 feet) that are extremely true flat and use our nearly seamless assembly process.

This is the most high-end and expensive process where we perform the highly specialized meticulous work in our factory yielding the high level of perfection that many of our most discerning clients require. See: our clients.

These must be manufactured in our plant to ensure accuracy with tolerances within thousandths of an inch and are more costly to ship due to the nature of their being larger than multiple panels that can be assembled on-site.

With the wide variety of applications for Sing Core panels, posts and beams, and equally diverse selection of fasteners are used in practical installations. Here are some of the most popular fastening systems used today:Norse Inc. LatchesNorse latches are designed for concealed installation in Sing Panels. Multiple configurations of latches and receivers are possible to suit many applications, and offer numerous advantages.Click Here for More Information …Knape & Vogt Manufacturing Company Here are some of the most popular fastening systems used today:Norse Inc. LatchesNorse latches are designed for concealed installation in Sing Panels. Multiple configurations of latches and receivers are possible to suit many applications, and offer numerous advantages.Click Here for More Information …Knape & Vogt Manufacturing Company

Click Here for More Information … Pan American Screw An International leader of innovative threaded fastening solutions. Developers of the Draw Bolts and Zipbolt™ tight joint fasteners. They are constantly testing and developing fasteners that are easier, faster and less costly to use. Click Here for More Information … FastCap

Click Here for More Information … ITW Fastex The range of panel fasteners and plastic clips available from ITW Fastex is designed to fill most fastening requirements. The range of applications is wide from machines, appliances, and computers to recreational vehicles and point of purchase displays. Click Here for More Information … Shur-Lok fasteners and components are designed to satisfy customer requirements in two general application ideas: secondary structures, such as interior stow bins, lavatories and galleys, and primary structures, such as aircraft engines, engine pylons, landing gears, wings, gearboxes, transmissions and helicopter rotors–all critical applications. Click Here for More Information … Veck Fasteners Special and bespoke bonding fasteners. In addition to Veck Fasteners standard range of popular bonding fasteners, we provide purpose-designed special and bespoke bonding fasteners for customers who have specific requirements which cannot be fulfilled from our standard range. Click Here for More Information … Just to name a few… |

Fasteners and Anchors for Sandwich panels

CEL FASTENERS are innovative tools to anchor and attach and remove sandwich panels easily and quickly.

The advantages of CEL’s fasteners are:

- Possibility to attach and detach the panels quickly to carry out maintenance work or substitution

- Invisible bolts

- Precise positioning and multiple removals

- Quick assembly

- Cost reduction

Initially developed in compliance with to the needs of shipyards, this anchoring system is more and more used in different sectors:

- Shops’, hotels’ and trade fairs’ assembly

- Lifts

- Transport: buses, trains, vans, etc.

- Carpentry

- Furnishing

Implants

Implants

Solid wood implants can be placed anywhere inside your custom Sing Panels for attaching hardware or other anchoring, including lock blocks and the like.

Individual connection inserts can be specified at specific locations to meet all your connection method needs. These can include, potted inserts, Rivnuts, Helicoil inserts, blind inserts with tabs and spool inserts, just to name a few.

Liability disclaimer

The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.

Examples of Joining Sing Panels