Here’s another great example of how straight a SingCore door is.

See other great examples of SingCore hinged doors here.

Here’s another great example of how straight a SingCore door is.

See other great examples of SingCore hinged doors here.

By popular demand SingCore introduces patented door core in economical and easy-to-use standard door width door blanks.

By popular demand SingCore introduces patented door core in economical and easy-to-use standard door width door blanks.

Until now, these SingCore standard door width door blanks were only available to high end door manufacturers making exotic doors for multimillion dollar homes. Some of the large entry doors can run as high as $50,000.00 or more. What happens when the owner of a mansion wants the doors throughout the whole house made with the same SingCore throughout the whole house?

We make standard door width door blanks for the door manufacturers to use in their door manufacturing facility.

Now, all the doors can match, with the same appearance and finish while having SingCore inside.

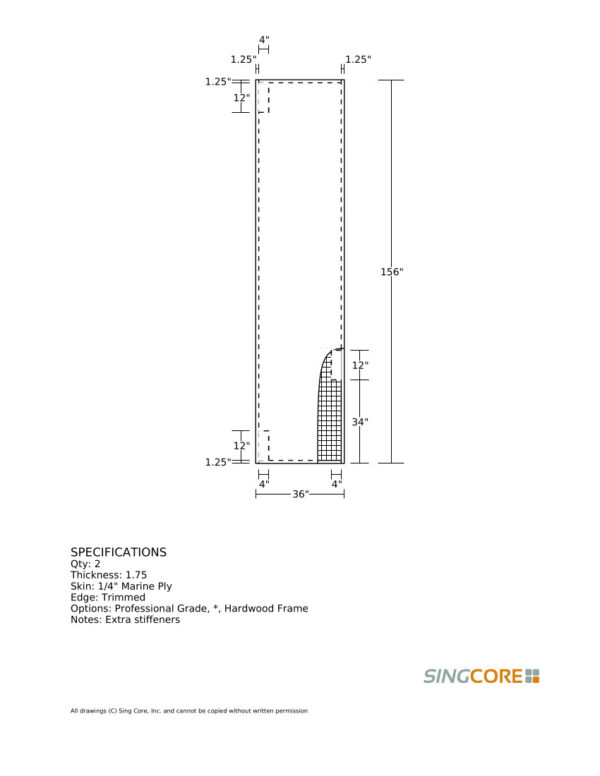

The Sing Standard Door Width Door Blank is conveniently sized for standard-sized door manufacturers. Every Sing Standard Door Width Door Blank measures 36 inches wide and a full 96 inches tall to accommodate all the most popular door sizes made by manufacturers of standard size doors.

The standard door width material measures 36x96x1.5 inches, features 1/4 inch smooth Birch skins and accommodates the manufacturing of all the most popular interior door sizes as well as standard exterior door sizes:

Sing standard door width door blanks are cut to size by the millwork or door manufacturer and used as a high end alternative to standard door core material.

Standard sizes available of Sing standard door width blanks include 96 inches x 36 inches, in your choice of four thicknesses, including 1.5 inch, 1.375 inch, 1 inch and 3/4 inch to suit your door making needs, or for use in other applications also.

Upscale door manufacturers are seeing the Sing light and looking at new ways to reimagine the way they make their traditional stile and rail doors. Now you can create a true raised 6 panel door the SingCore way by staring with a Sing standard door width door blank and cutting it to size. Then add wood frame and final skin, finishing, hand and install for s superior insulated (sound deadening), lightweight, high strength door that can be guaranteed not to warp or structurally fail for 50 years.

Examples of molding added to Sing Sandwich Panels

Why Use SingCore Inside Standard Door Width Doors?

Why Use SingCore Inside Standard Door Width Doors?The only way to keep any large oversized door from warping or otherwise failing is to make the large door with SingCore inside as this is the only method providing a full 50 year warp-free guarantee, but that’s not the only reason SingCore is specified by the most prestigious architects or requested by demanding clients specifying doors with SingCore inside.

The world’s best and most expensive doors that have SingCore inside are imbued with unique characteristics that are more commonly requested by luxury homeowners of mansions, like Eco –friendly, lightweight, high strength, warp-free, insulated and fully guaranteed. Here’s why:

Helping door manufacturers deliver high end doors that are lighter in weight than standard solid doors, means less labor and risk of injury on the job site. Also, it equates to increased economy and reduction of service calls due to hardware failure due to added stress and strain on both the structure and hardware due to heavy weight doors.

No light weight door core material is stronger. In fact SingCore has been independently tested and rated at 660 PSI, that’s stronger than steel pound for pound, which also enables SingCore doors to be made…

No light weight door core material is stronger. In fact SingCore has been independently tested and rated at 660 PSI, that’s stronger than steel pound for pound, which also enables SingCore doors to be made…

Patented SingCore doors can be made to be warp-free using composite technology of SingCore and patent pending warp-free technologies that can be guaranteed to remain warp-free and be fully guaranteed for full structural integrity for 50 years.

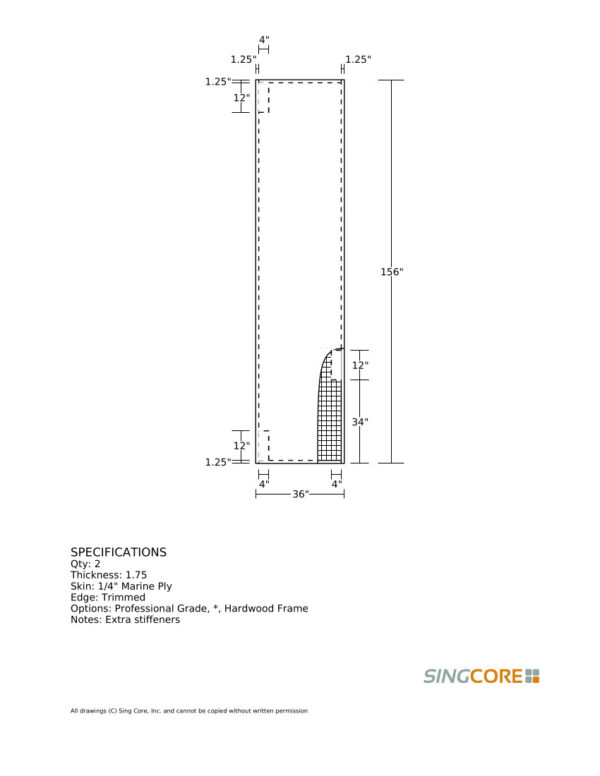

The patented insulated reinforced torsion box core is packed with insulation that offers the benefits of both greater climate control and sound-deadening qualities on either side of the door with SingCore inside.

Thanks to the increasing demand of SingCore standard door width door blanks, we have decided to set-up standard production lines to make this convenient door core commodity available to all professional door makers who would like to offer these high end doors to their clientele.

Because we can make and ship SingCore standard door width door blanks by the truckload, we have these Birch-skinned 36 x 96 x 1.5 inch patented door cores available at lower wholesale prices for use and standard door making material in any door factory.

Of course, we always are available to all millworks and door manufacturers, to help provide the best door manufacturing assistance available. Our convenient OEM services can provide additional levels of support on large orders, where we can do much of the pre-fab-work for you, in advance.

Feel free to order high end one-off, or in bulk, your door blanks can be made-to-size and pre-skinned in any exterior material, like any available wood species, aluminum, concrete, fiberglass, glass, HPL, Kevlar, LVL, MDF, metal, plastic, cold rolled steel, hot rolled steel, galvanized steel or stainless steel, just to name a few.

SingCore is announcing more standard products available for construction, furniture and casegoods manufacture, including

All the other standard products include the same SingCore Inside benefits.

Exclusive to multimillion dollar spec homes, the standard extra wide exterior doors are pivot doors to accommodate the unique challenges of wide doors.

Exclusive to multimillion dollar spec homes, the standard extra wide exterior doors are pivot doors to accommodate the unique challenges of wide doors.

Wide doors will warp, not just top to bottom but side to side which compromises the seal and creates a problem for latching the door. Wide doors are problematic due to warping requiring regular maintenance to adjust the wide door accordingly.

The Sing non-warping Professional Pivot Door Panels are the solution because if the door does not warp, you’ve solved the problem with the failure of wide doors altogether, and can be guaranteed to remain non-warp for 50 years. Even $10,000 wide doors cannot be guaranteed not to warp; even for one day.

This wide door could use concealed door hinges as swing door hinges or pivot door hardware for extra wide exterior doors thanks to Sing Core.

Using the Sing non-warp door blank as the basis extra wide exterior doors used in multimillion dollar spec homes is not only the only solution, but also imbues your door with the following benefits:

Using the Sing non-warp door blank as the basis extra wide exterior doors used in multimillion dollar spec homes is not only the only solution, but also imbues your door with the following benefits:

Expensive pivot doors start at about $10,000 and just the hardware (due to the heavy weight of the door) can run into thousands of dollars and requires highly skilled craftsmen to install/maintain.

Sing wide door are a fraction of the weight and price of extra wide exterior doors. Due to being so lightweight, less expensive pivot door hardware can be used. In fact because Sing wide doors are so light in weight, you can even use standard hinge door hardware. This is why Sing wide door blanks are the premium choice of high end carriage door manufacturers.

Sing wide door are a fraction of the weight and price of extra wide exterior doors. Due to being so lightweight, less expensive pivot door hardware can be used. In fact because Sing wide doors are so light in weight, you can even use standard hinge door hardware. This is why Sing wide door blanks are the premium choice of high end carriage door manufacturers.

Now, wide doors need not be relegated only to million dollar homes, because making them more affordable puts them within the reach of discriminating home owners who would like to increase the impact of their entrance door by switching to an extra wide front door.

Say, “goodbye,” to sidelites. Sing wide doors can easily be retro-fitted to replace a standard existing exterior front door and sidelites with a single Sing extra wide front door using your choice of side hinges or pivot door hardware.

Sing Wide Doors Always Latch

Sing Wide Doors Always LatchThe difference between sing wide doors and any other extra wide door is that you can always count on one thing: Sing wide doors will always secure and latch every time because they will not warp nearly eliminating wide door maintenance. This high precision can be guaranteed non-warp for 50 years.

Thanks to the light weight of Sing Door blanks, you can choose whether your extra wide exterior doors use side hinges (we suggest considering the use of concealed SOSS hinges) or lightweight pivot door hardware for easy hardware installation.

|

|

|---|---|

|

Craned up to Manhattan highrise.

|

Click to enlarge

|

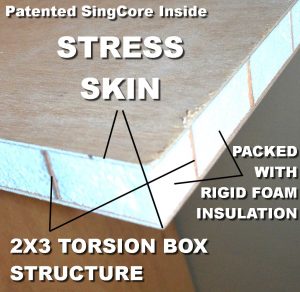

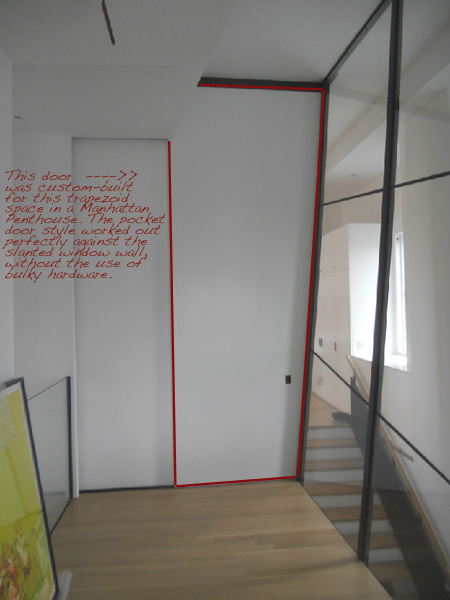

This custom made trapezoid door traveled over 2,921 miles from coast to coast, now on final leg of its journey to its new home in upscale Manhattan apartment.

We specialize in custom sizes, shapes and thickness to fit our

customer’s needs, we offer the best guarantee in the door business.

|

|

|---|---|

|

Door Open

|

Door Closed

|

As low as $50 a door for a door that will last a lifetime.

|

|

|---|---|

|

Punch proof Sing Core door.

|

Typical paper core door. (click to see more)

|

Today, the most common doors found in private residences contain a paper core. These doors are flimsy and are easily punctured, even when slightly impacted. Owners of these doors find themselves spending time and money on repairs, replacements, and installations that would not have been an issue had they purchased a door from Singcore. Singcore doors do not cost much more than paper-core doors, yet they have been tested to be at least 49 times stronger.

How secure are your doors? With our patented core, you can rest assured that our torsion box technology will stand up to harsh treatment and all weather conditions. Our doors have been thoroughly tested and have been proven to withstand the impact of a sledgehammer. There is no comparison between the stability, structure, and strength of Sing Core doors versus paper-core doors.

This is a Sing Overhead Garage Door Panel compared next to a typical steel overhead garage door panel. Same size and thickness but as you can see the steel panel buckles with only a few pounds put on it while the Sing Panel holds almost all of Inventor Peter Sings weight without any problem.

Doors do not have to be made out of steel to be rigid and strong. Sing Core doors are stronger and lighter, than steel and vinyl doors. Standard steel overhead garage doors are made of steel so thin that a golf ball can dent it. This is not the case with Sing Core doors. We offer higher quality doors at prices competitive with steel doors with quality superior to wooden doors.

Sing Core doors are more stable, provide better insulation, and are far lighter than solid wood doors. The torsion-box core holds the Sing Core door flat, ensuring that that the panel will not warp and sag like ordinary wood.

Sing Core doors are versatile and customizable. Every order is custom designed with the client’s project in mind. Each door is constructed using methods that specifically cater to our customers’ individual needs. We construct our doors using the following methods: pole barn grade, paint grade, wood grain grade, and plank grade.

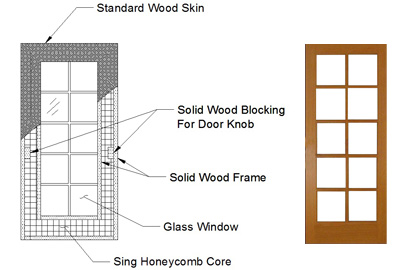

The easiest way to build the best doors.

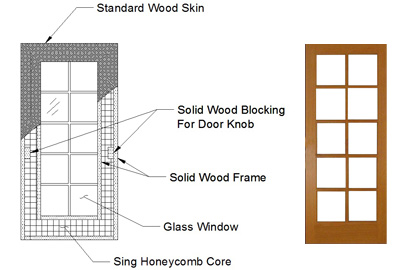

Step 1 – Apply Glue to the Skin

Step 2 – Build Solid Wood Frame

Step 3 – Install the patented Sing honeycomb torsion box core & press on the skins.

Step 4 (optional) – Cut hole for window and prepare window trim.

Step 5 (optional) – Install glass and finish the door to desired look and function.

Step 6 – Install the door onto jam.

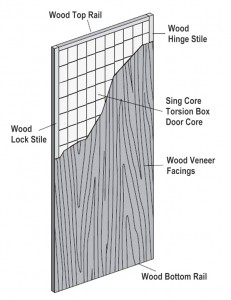

On the left are patented Sing honeycomb stile and rail. On the right is veneer (walnut) ready for gluing onto the patented Sing honeycomb stile and rail.

Apply glue to our patented Sing honeycomb stile and rail.

Press veneer to patented Sing honeycomb stile and rail. Most honeycomb panels cannot handle the high pressure and temperatures of the hot press, Sing honeycomb can.

Stile and Rail after the veneer has been pressed on.

See how straight the patented Sing honeycomb stile and rail are, yet they are still incredibly strong and lightweight.

Drill holes to accept dowels.

Doweled and glued.

Router out the end if hardware is to be installed

Stained and ready for glass and installation.

|

|

|---|

Pictures courtesy of Robert Shaw – www.robertshawmfg.com

Doors 8′ – 7″ tall

Sing Door Panels are easy to order (link). You may select panels of standard dimensions from our inventory, or you may order custom sizes and shapes. Please submit a Work Order by fax or email, and we will get back to you with a free quote within one business day. You only need to submit the length, width, thickness and quantity. Even if you have an unorthodox idea or a tight budget, give us a call. Our representatives will help devise an alternative solution tailored to your needs.

Sing Core allows you to design your own doors. Just add trim, paint, and hardware*. Exceptional pricing is available to distributors, manufacturers, and retailers

. Doors Pamphlet For Distributors

**Wholesale prices available to licensed dealers/installers.

*For retail customers, please contact your local garage door installer/dealer.

| Sing Door Assembly | Sing Door Strength Demo |

Standard sandwich panels utilize an insulating foam core sandwiched in between two thin sheets of hard material. However, this design offers very little strength and durability. Sandwich panels made by Sing Core are stronger, lighter, and more eco-friendly than these conventional panels because we replace the standard foam core with our patented vertical grain, natural veneer torsion box grid also known as the Sing Core. For the consumer, this translates into a higher quality product at a fraction of the cost.

(click to visit our product gallery)

Insulated doors made with traditional sandwich panels are highly susceptible to dents and structural damage because of their weak foam core. Doors made with our Sing Core sandwich panel technology can withstand much higher impacts resulting in little or no damage due to our unique core properties. The University of Washington has confirmed that our doors can withstand pressure of up to 660 psi, as compared to the average sandwich panel which can only withstand 60-100 psi.

How can Sing Core sandwich panels be used? Doors, shelving, table-tops, flooring, bookcases, furniture, outdoor decking material, truck/trailer beds even water tanks, to name a few. The possibilities are endless.

If you desire products that are lightweight, strong, durable, dimensionally stable, and eco-friendly, then you must try our Sing Core Sandwich Panels. We like to demonstrate our confidence in the integrity of our products by offering our customers a 10 year structural guarantee.

(click to visit our product gallery)

Since our company’s inception, our products have made in the U.S.A..

Please share this message with your friends and business associates.

Or fill out our Work Order Form to get a free quote.

Simple Joining

The simplest and least expensive way to join sing panels is to join in any way according to your budget and/or expertise.

Due to Sing Panels being so straight and true it is easier to join panels together because they line up perfectly unlike other building materials.

In many cases, for instance, standard 4×8 panels can be nailed, glued or channel-joined quickly and easily with satisfactory results.

In many cases, for instance, standard 4×8 panels can be nailed, glued or channel-joined quickly and easily with satisfactory results.

Other options for fastening panels may include cam locks (see examples left and right) that can be pre-installed, making assembly and joining easy and more secure.

Thru-bolt Joining

One of the most inexpensive and secure ways to join sing panels is by utilizing a simple nut and bolt connection method, especially, if the panels will be routinely or repeatedly assembled and disassembled.

Stainless steel nuts and bolts offer the safety and security when joining sing panels.

Biscuit Joining

In many cases, Sing Panels can be pre-configured for biscuit joining at your site of factory.

Especially for large projects, this enables Sing Core panels to be sent individually, reducing shipping and handling costs, for assembly at your facility or job site.

See images below for example of biscuit assembly of Sing Panels

Joining With H Channel and H Molding

Embedded T-Slot Extruded Aluminum

In your choice of T1 (1 exposed slot) or T3 (3 exposed slots)

See: Sing T Slot Panels for more information.

Edge Banding

Unless specified Sing Panels do not ship edge-banded as 93% of our wholesale customers do their own edge-banding when finishing their Sing Panel.

Edge banding can take many forms from vinyl and plastic to wood and steel. Sing Panels are not intended for use as an un-banded product and may not qualify for our 50 year warranty if un-banded.

If your intention is to get the best, most long-lasting performance from your Sing Panels, feel free to take advantage of our free consultation to be guaranteed to achieve the results that you desire.

Edge Banding Options Include:

T Molding

Here is an example of a large lightweight high-strength non-warping sliding door.

Here is an example of a large lightweight high-strength non-warping sliding door.

Note the steel T molding being installed to complete the door’s composition.

This door is guaranteed not to warp, bend, twist or otherwise fail due to being properly engineered and manufactured to exceed the specifications of this oversized architectural door.

T Molding

L Molding

Flat Molding

U Channel

Advanced Large Panels

Sing Core specializes in extremely large panels (up to 50 feet) that are extremely true flat and use our nearly seamless assembly process.

This is the most high-end and expensive process where we perform the highly specialized meticulous work in our factory yielding the high level of perfection that many of our most discerning clients require. See: our clients.

These must be manufactured in our plant to ensure accuracy with tolerances within thousandths of an inch and are more costly to ship due to the nature of their being larger than multiple panels that can be assembled on-site.

|

With the wide variety of applications for Sing Core panels, posts and beams, and equally diverse selection of fasteners are used in practical installations. Here are some of the most popular fastening systems used today:Norse Inc. LatchesNorse latches are designed for concealed installation in Sing Panels. Multiple configurations of latches and receivers are possible to suit many applications, and offer numerous advantages.Click Here for More Information …Knape & Vogt Manufacturing Company Here are some of the most popular fastening systems used today:Norse Inc. LatchesNorse latches are designed for concealed installation in Sing Panels. Multiple configurations of latches and receivers are possible to suit many applications, and offer numerous advantages.Click Here for More Information …Knape & Vogt Manufacturing Company

Click Here for More Information … Pan American Screw An International leader of innovative threaded fastening solutions. Developers of the Draw Bolts and Zipbolt™ tight joint fasteners. They are constantly testing and developing fasteners that are easier, faster and less costly to use. Click Here for More Information … FastCap

Click Here for More Information … ITW Fastex The range of panel fasteners and plastic clips available from ITW Fastex is designed to fill most fastening requirements. The range of applications is wide from machines, appliances, and computers to recreational vehicles and point of purchase displays. Click Here for More Information … Shur-Lok fasteners and components are designed to satisfy customer requirements in two general application ideas: secondary structures, such as interior stow bins, lavatories and galleys, and primary structures, such as aircraft engines, engine pylons, landing gears, wings, gearboxes, transmissions and helicopter rotors–all critical applications. Click Here for More Information … Veck Fasteners Special and bespoke bonding fasteners. In addition to Veck Fasteners standard range of popular bonding fasteners, we provide purpose-designed special and bespoke bonding fasteners for customers who have specific requirements which cannot be fulfilled from our standard range. Click Here for More Information … Just to name a few… |

||||||||||||||||

CEL FASTENERS are innovative tools to anchor and attach and remove sandwich panels easily and quickly.

The advantages of CEL’s fasteners are:

Initially developed in compliance with to the needs of shipyards, this anchoring system is more and more used in different sectors:

Implants

ImplantsSolid wood implants can be placed anywhere inside your custom Sing Panels for attaching hardware or other anchoring, including lock blocks and the like.

Individual connection inserts can be specified at specific locations to meet all your connection method needs. These can include, potted inserts, Rivnuts, Helicoil inserts, blind inserts with tabs and spool inserts, just to name a few.

The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.

Examples of Joining Sing Panels

Patented Sing Core: We put a torsion box in the SIP panel to make it better. The other names for our panels include sandwich panel, honeycomb panel and lightweight panel.

|

|

|---|---|

|

Punch proof Sing Core door.

|

Typical paper core door. (click to see more)

|

What door companies do not want you to know.

As long as you cannot see the paper core hide inside the door, they will not change it to Sing core. Sing core does not cost not much more than core made of paper but is at least 49 times stronger.

As long as you cannot see the paper core hide inside the door, they will not change it to Sing core. Sing core does not cost not much more than core made of paper but is at least 49 times stronger.

Punch through a Sing door and you will break your hand. If you can manage to punch through a Sing core punch-proof door and don’t break your hand then you will get a free sing door from us.

The most common doors used in most homes are paper core doors. With one punch you can destroy one of these flims doors. Once the door is broken you will need to take it to a door shop to get if fixed or replaced and then take it back and install it. The cost is not only a door, it is how to dispose of it, take it in and out of the shop, build or replace the door and install it. Why not just buy a Sing door to begin with. Sing doors are not much more expensive than paper core doors when consider the life span and they are free. What is your time worth?

Your door doesn’t have to be steel to be strong. Sing Honeycomb Doors are stronger, lighter and more stylish than steel and vinyl doors due to the torsion box core.

Sing Doors are more stable, insulated and lightweight than solid wood doors. The torsion box core holds the Sing Door Panel flat so that it willnot warp and sag like ordinary wood. A 16lb steel hammer will easily dent a steel or vinyl door, but not a Sing Door. Because Sing panels are efficient to produce, they are more affordable than solid wood doors.

Sing Honeycomb doors are versatile, and customizable. Even the technoly used to construct the door can cater to our customers’ individual needs.

To see more torsion box pictures and web sites visit the Google image galery.

SING CORE Fiberglass (FRP) & Plastic

The cut away of the Sing Core panel show the patented core that makes the difference. If you want the best panel or door available make sure you use Sing Core.

Patented Sing Honeycomb Fiberglass door (10′ x 3′ x 2.25″). Ready for fiberglass edge banding.

Lightweight, high strength finished fiberglass French door.

Deflection test of a finished fiberglass trailer deck.

Fiberglass trailer deck (13′ x 6′). Very strong but lightweight.

The underside of the fiberglass trailer deck.

Fiberglass water tank can be used for a hot tub, fish tank or even water storage.

7′ x 3′ fiberglass door with blue gel coat.

| Sing Door Strength Demo |

80% of the doors we sell are true flat large oversize doors (over 4 ft. x 8 ft.), though we do specialize in 5% regular-sized doors.

Custom Lite Openings for Glass – No Extra Charge

The door is a moving structure used to block access, visibility and noise between two otherwise connected areas. The door as we know it is moving to the next level of high-performance, safety and security thanks to patented Sing Core.

This new door revolution is introducing a new evolution in door technology that delivers an insulated door that is true flat, lightweight, stronger than steel and Eco-friendly. Sing Core doors are the high-end solution used by the best millworks when it’s important to deliver the best door.

Enjoy the safety and security of a door that cannot be easily breached and is much safer for finger and limb injuries due to the lighter weight than conventional doors. Sing Core doors are available in any door configuration and/or size and available to all door manufacturers.

Types of Doors

Types of Doors Fiberglass Doors

Fiberglass Doors Clients List

Clients List

Patented Sing Core: We put a torsion box in the SIP panel to make it better. The other names for our panels include sandwich panel, honeycomb panel and lightweight panel.

|

|

|---|---|

|

Craned up to Manhattan highrise.

|

Click to enlarge

|

This custom made trapezoid door traveled over 2,921 miles from coast to coast, now on final leg of its journey to its new home in upscale Manhattan apartment. We specialize in custom sizes, shapes and thickness to fit our customer’s needs, we offer the best guarantee in the door business.

|

|

|---|---|

|

Door Open

|

Door Closed

|

As low as $50 a door for a door that will last a lifetime.

|

|

|---|---|

|

Punch proof Sing Core door.

|

Typical paper core door. (click to see more)

|

Today, the most common doors found in private residences contain a paper core. These doors are flimsy and are easily punctured, even when slightly impacted. Owners of these doors find themselves spending time and money on repairs, replacements, and installations that would not have been an issue had they purchased a door from Singcore. Singcore doors do not cost much more than paper-core doors, yet they have been tested to be at least 49 times stronger.

How secure are your doors? With our patented core, you can rest assured that our torsion box technology will stand up to harsh treatment and all weather conditions. Our doors have been thoroughly tested and have been proven to withstand the impact of a sledgehammer. There is no comparison between the stability, structure, and strength of Sing Core doors versus paper-core doors.

This is a Sing Overhead Garage Door Panel compared next to a typical steel overhead garage door panel. Same size and thickness but as you can see the steel panel buckles with only a few pounds put on it while the Sing Panel holds almost all of Inventor Peter Sings weight without any problem.

This is a Sing Overhead Garage Door Panel compared next to a typical steel overhead garage door panel. Same size and thickness but as you can see the steel panel buckles with only a few pounds put on it while the Sing Panel holds almost all of Inventor Peter Sings weight without any problem.

Doors do not have to be made out of steel to be rigid and strong. Sing Core doors are stronger and lighter, than steel and vinyl doors. Standard steel overhead garage doors are made of steel so thin that a golf ball can dent it. This is not the case with Sing Core doors. We offer higher quality doors at prices competitive with steel doors with quality superior to wooden doors.

Sing Core doors are more stable, provide better insulation, and are far lighter than solid wood doors. The torsion-box core holds the Sing Core door flat, ensuring that that the panel will not warp and sag like ordinary wood.

Sing Core doors are versatile and customizable. Every order is custom designed with the client’s project in mind. Each door is constructed using methods that specifically cater to our customers’ individual needs. We construct our doors using the following methods: pole barn grade, paint grade, wood grain grade, and plank grade.

Sing Door Panels are easy to order (link). You may select panels of standard dimensions from our inventory, or you may order custom sizes and shapes. Please submit a Work Order by fax or email, and we will get back to you with a free quote within one business day. You only need to submit the length, width, thickness and quantity. Even if you have an unorthodox idea or a tight budget, give us a call. Our representatives will help devise an alternative solution tailored to your needs. Sing Core allows you to design your own doors. Just add trim, paint, and hardware*. Exceptional pricing is available to distributors, manufacturers, and retailers . Doors Pamphlet For Distributors

| Sing Door Assembly | Â Sing Door Strength Demo |

See the Sing Best Door definition Sing Core specializes in custom 1-off high-end large oversized doors, sliding doors and aluminum doors. Why? Because no other door manufacturers does huge eco-friendly doors better. The Sing Core Door manufacturing plant is set up especially to make doors that are up to 50 feet tall, yet true flat, lightweight and stronger than steel.  Huge doors present a variety of complications for designers and installers. Due to structural changes in the materials and changes in the physical environment. A door that appears to be a perfect fit at the time of installation, most likely will be a huge disappointment over time. This causes extraneous maintenance fees, loss of energy, and lack of long life requiring early replacement.

Huge doors present a variety of complications for designers and installers. Due to structural changes in the materials and changes in the physical environment. A door that appears to be a perfect fit at the time of installation, most likely will be a huge disappointment over time. This causes extraneous maintenance fees, loss of energy, and lack of long life requiring early replacement.

Sing Core large doors are not only Eco-friendly, lightweight and stronger than steel, they are extremely affordable when compared to other lightweight but strong materials. The best-known, oldest, most reliable, high-end millworks in the United States depend on Sing Core to deliver the goods for them when it comes to large, oversize doors. Why? Because Sing Core large doors are the only oversized doors that can outperform any other door in terms of long-lasting satisfaction and guaranteed true flat. Just let us know your expectations and based on our expertise, we will be able to provide you with a solution that we can guarantee. Challenges of door manufacturing are based on three factors: 1. The skin (surface material) 2. The thickness 3. Door size Based on years of experience, we know how to manipulate those numbers to your best advantage to make certain that you get the results you desire. If you’re considering an immense large interior or exterior door, you should consider a Sing Core large oversize door that comes with a full 10-year structural warranty. Some of our design solutions include very large doors, like large French doors, large carriage doors, large closet doors, large cabinet doors, large guillotine doors and large front doors and in most cases to guarantee true flatness aluminum plays a part in the composite design. Sing Core oversized entry doors, oversized French doors, oversized front door, oversized interior doors, large glass doors, large patio doors and large entry doors by far exceed the requirements of any other doors available on the market today. When it comes to large exterior doors, large pocket door, large interior doors, large glass sliding doors, large garage doors or large wooden doors no other door manufacturers can deliver superior results, like Sing Core. Whether you’re considering a large sliding glass door, large wood doors, large sliding doors exterior, large shop doors, large opening doors or large pivot doors, Sing Core is your one-stop solution for your oversize door, guaranteed.

Sing Core large doors are not only Eco-friendly, lightweight and stronger than steel, they are extremely affordable when compared to other lightweight but strong materials. The best-known, oldest, most reliable, high-end millworks in the United States depend on Sing Core to deliver the goods for them when it comes to large, oversize doors. Why? Because Sing Core large doors are the only oversized doors that can outperform any other door in terms of long-lasting satisfaction and guaranteed true flat. Just let us know your expectations and based on our expertise, we will be able to provide you with a solution that we can guarantee. Challenges of door manufacturing are based on three factors: 1. The skin (surface material) 2. The thickness 3. Door size Based on years of experience, we know how to manipulate those numbers to your best advantage to make certain that you get the results you desire. If you’re considering an immense large interior or exterior door, you should consider a Sing Core large oversize door that comes with a full 10-year structural warranty. Some of our design solutions include very large doors, like large French doors, large carriage doors, large closet doors, large cabinet doors, large guillotine doors and large front doors and in most cases to guarantee true flatness aluminum plays a part in the composite design. Sing Core oversized entry doors, oversized French doors, oversized front door, oversized interior doors, large glass doors, large patio doors and large entry doors by far exceed the requirements of any other doors available on the market today. When it comes to large exterior doors, large pocket door, large interior doors, large glass sliding doors, large garage doors or large wooden doors no other door manufacturers can deliver superior results, like Sing Core. Whether you’re considering a large sliding glass door, large wood doors, large sliding doors exterior, large shop doors, large opening doors or large pivot doors, Sing Core is your one-stop solution for your oversize door, guaranteed.

Solid like a rock, light like feather so you don’t smash your finger.

If your sliding doors are large, you probably have to deal with the issues of added weight that can be problematic. Lightweight Sing Core’s torsion-box substrate is the answer to dealing with the issues of weight of large sliding doors yet adds high structural integrity, and helps to prevent injury to the end-user(s). Wood sliding patio doors, sliding glass doors, and even the most high-fashion vinyl sliding patio door can be expertly engineered with patented Sing Core technology. Strengthening outdoor sliding doors and reducing the weight helps to protect and reduce maintenance to expensive sliding door hardware as well as added stress and strain on the structure. When considering your sliding door ideas, think about the size, the weight and the structural integrity of your sliding door system over time.

If your sliding doors are large, you probably have to deal with the issues of added weight that can be problematic. Lightweight Sing Core’s torsion-box substrate is the answer to dealing with the issues of weight of large sliding doors yet adds high structural integrity, and helps to prevent injury to the end-user(s). Wood sliding patio doors, sliding glass doors, and even the most high-fashion vinyl sliding patio door can be expertly engineered with patented Sing Core technology. Strengthening outdoor sliding doors and reducing the weight helps to protect and reduce maintenance to expensive sliding door hardware as well as added stress and strain on the structure. When considering your sliding door ideas, think about the size, the weight and the structural integrity of your sliding door system over time.

SAFETY AND SECURITY

The Sing Core sliding door offers so much more than luxury, but also increases safety and security of the homeowner’s family, the contractors and workers, as traditional overweight sliding doors have been known to be unsafe and can cause injuries threatening life and limb. Reduce liability of your contractors and commercial clients by reducing on-the-job injuries and help to protect the lives of your clients and their families in residential settings. Even the best health insurance cannot replace a finger that has been crushed by a heavy sliding door.

GUARANTEED TRUE FLAT

When it comes to sliding doors for walk in closets, most people don’t recognize the importance of remaining true flat inside the pocket door frame. Whether you’re looking for a pocketed door system, wall-mounted system, hanging or floor track system, you can experience the superior performance of your single French door, fiberglass French door or exterior French door because you’ve been introduced to the best sliding French doors for sale on the market today. Exterior sliding barn doors can be beautiful following installation, but after time, problems develop due to door failure. They tend to expand and contract due to weather exposure causing them to warp, twist, and crack, compromising the overall performance of your sliding barn door system. Even a 1/4″ deflection can compromise an otherwise aesthetically pleasing completed project. Sing Core’s true flat guarantee is why high-end millworks and designers seek out Sing Core for extreme weather and temperature-controlled environments. For the do it yourselfer, DIY sliding closet doors can also be a challenge, and Sing Core can help to bridge the gap between the solo sliding door project. Sliding closet doors are gaining popularity amongst discerning builders and designers, while wooden sliding closet doors are extremely attractive, infusing Sing Core technology can save your interior sliding doors from warping, twisting and/or cracking, so that you can enjoy the elegance and functionality of your sliding door for lifetimes with little or no maintenance.

Photo courtesy Woodbourne Design Studio

No company excels in building sliding doors that are much larger than the standard 8 foot sliding patio door. Sing Core specializes in building extreme oversize, large sliding doors that are true flat and guaranteed. When you’re designing a double sliding door system, the true flat advantages of Sing Core helps to maintain the structural integrity, keeps the sliding of the doors from interfering with the perfect functionality and long-term efficiency. And increase in interior design trends, like the wall mounted sliding door, Sing Core is the sliding doors company that can get your from here to there whether you are looking for a sliding door for bathroom, sliding barn door kits, sliding door dividers. Sing Core is your preferred resource if you want to avoid cheap sliding patio doors. Sliding fire doors are gaining popularity in the Sing Core sliding door lineup. Regardless of the wide variety of types of sliding doors, Sing Core offers the elegance and excellence in barn door sliding door, sliding office doors, and exotic sliding doors, like, Chinese sliding doors, sliding French doors exterior, Shoji screen sliding doors and/or Japanese style sliding doors. Barn door interior sliding doors come in a variety of materials that are virtually unlimited to match your aesthetic tastes including, aluminum patio sliding doors. Sing Core makes the best real sliding door that solves the challenges that face architects and designers around the world for the best results, guaranteed.

We guarantee that we are the only company in the world that can deliver true flat oversize doors that meet your expectations, if you desire a true flat solution, especially in the large, oversize door.

One of the biggest challenges we see from designers and developers is that of the oversize door. Sure, anyone could make an oversize door, but can you make one that is true flat, maintaining structural integrity over long spans? That’s where Sing Core shines.

3 Types of Oversize Doors

There are three types of oversize door solutions, and in terms of meeting or exceeding the needs of the most high-end clients in the world. Our specialty is solving the problems associated with large oversize doors, while maintaining true flatness under extreme circumstances is unheard of, Sing Core helps us achieve the results that no one else can and remain lightweight and Eco-friendly, too. 1. Large Oversize Wood Door The large oversize wood door has been a challenge for centuries because regardless of your expectations or requirements, the very nature of wood itself will provide additional challenges for both designer and the design. Not until the invention of Sing Core has there been a perfect solution for the issues associated with large oversize wood doors. See more information on Large Oversize Wood Doors. 2. Large Oversize Aluminum Door For more extreme oversize solutions the Sing Aluminum Door is the better solution, especially when doors are expected to remain true flat under varying conditions. Aluminum has certain attributes that help us reach and exceed the requirements of the most demanding high-end clients. See more information on Large Oversize Aluminum Doors. 3. Large Oversize Wood/Aluminum Composite The best solution for battling the issue of oversize without compromising the look, feel, beauty and elegance of solid wood is to call in the specialists at Sing Core to help design the perfect solution to your strictest concerns and requirements. See more information on Large Oversize Wood/Aluminum Composite. 4. Large Oversize FRP Composite Door If your large oversize door will be facing extreme weather conditions, temperature variations, or some other kind of added stress that might be above what would be considered normal exposure. Every day someone finds the Sing Core solution. For instance, when O.B. Williams needs a hundred oversize doors, that are guaranteed flat, who do they turn to? They call Sing Core to get the job done. Plus, you have all the advantages of patented Sing Core, with any appearance that you like i.e., aluminum or exotic wood grain finish… In a hurry? No problem. Sing Core can build your true-flat oversize doors for you in less than 3 days, even though our normal turnaround is 2 to 6 weeks. Sing Core’s got your back. We make you look good. When your client demands only the best… You can confidently use Sing Core as your resource, because when it comes to oversize, true flat, nothing else even comes close. Any look you desire…  Oversize Sing Core doors can achieve any exterior surface your customer desires, including (but not limited to) any wood species you customer desires, concrete, fiberglass, aluminum, stainless steel, fire-resistant Magnesium Oxide (MgO) Board, bullet-proof Kevlar, etc… How do we do it? Oversize and true flat is a challenge that we take on every day. We know the perfect combination of patented sing core and aluminum, to maintain light weight, superior strength and true flat construction. This is how we build sustainable, high-end, true flat doors consistently and guaranteed for ten years.

Oversize Sing Core doors can achieve any exterior surface your customer desires, including (but not limited to) any wood species you customer desires, concrete, fiberglass, aluminum, stainless steel, fire-resistant Magnesium Oxide (MgO) Board, bullet-proof Kevlar, etc… How do we do it? Oversize and true flat is a challenge that we take on every day. We know the perfect combination of patented sing core and aluminum, to maintain light weight, superior strength and true flat construction. This is how we build sustainable, high-end, true flat doors consistently and guaranteed for ten years.