Seattle’s Center for Architecture and Design had their grand opening 7 years ago in March, 2016, and they have stood as a pillar for the architecture and design industry ever since. We are honored to have worked with the AIA to construct this beautiful place. Their confidence in us and our product was felt, as this was a major project that had a lot of work put in from start to finish. It all started with an amazing design plan and incredible vision for the limited space they had available, and together with the great teams working on this project we were able to build the wonderful gallery that can be seen today.

Seattle Center for Architecture and Design

As a chapter of the American Institute of Architects, the Seattle Center for Architecture and Design welcomes and promotes many different styles and techniques of architecture, hosting valuable presentations and events in their welcoming gallery. On display they have many different subjects of the architecture and design industries, and many people visit the center from open until close to see these marvelous features and discuss these themes.

During their grand opening, the Center for Architecture and Design was in need of some large, adjustable walls and doors to manipulate the gallery as needed. Their vision was to have walls that could be adjusted to create a beautiful, open space for guests, but could also be turned as to create a closed area to hold meetings and conferences. Sing Core donated the wall panels needed for this grand project, as well as customized them with additions such as a man door, allowing an easy entrance and exit even when the room had been closed off. The donated panels were actually so large that the front windows had to be temporarily removed, as the product would not fit through the door!

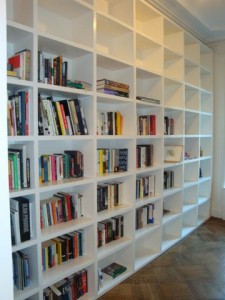

In addition to the adjustable walls and doors Sing Core donated, we also provided furniture for the office in the form of high end desks, shelving, partition walls, and more, all using our patented and patent-pending Sing Core products.

In addition to the adjustable walls and doors Sing Core donated, we also provided furniture for the office in the form of high end desks, shelving, partition walls, and more, all using our patented and patent-pending Sing Core products.

These grand adjustable walls are still in place today, and can be seen as a main piece of the Center’s gallery. They were created and still function to serve one main purpose: to maximize space in an innovative way. And while Sing Core is proud of our donation, we also owe a significant compliment to the incredible teams that designed the floor plan and installed the doors and walls, as their excellent skills and labor were just as essential in creating this space.

Texas Society of Architects

Texas Society of Architects

Sing Core also provided our panels at a discount to the Texas Society of Architects by AIA for use in their offices and building space. The location had a significant noise problem with their high, industrial style ceiling, and they needed high end panels to cut down on the echoes and residual sound. By installing Sing Core panels in strategic places, they were able to significantly cut down on the noise and establish a far more relaxed and focused work environment. Once again, this could not have been done without the incredible design and installation teams who perfectly utilized the Sing Core panels..

Conclusion

Sing Core is proud to be a platinum donor and support these AIA locations and the amazing things they do for the architecture and design community. If you are a member of the AIA, please share this article with your fellow AIA members, and we welcome you to reach out about any AIA project like these so that we can continue to help the organization, and we would be honored to do so at a discounted rate to help your budget. To learn more about the products provided to the Seattle and Texas locations, click here.

More Pictures of the Seattle and Texas AIA Donations